Brand & Engine

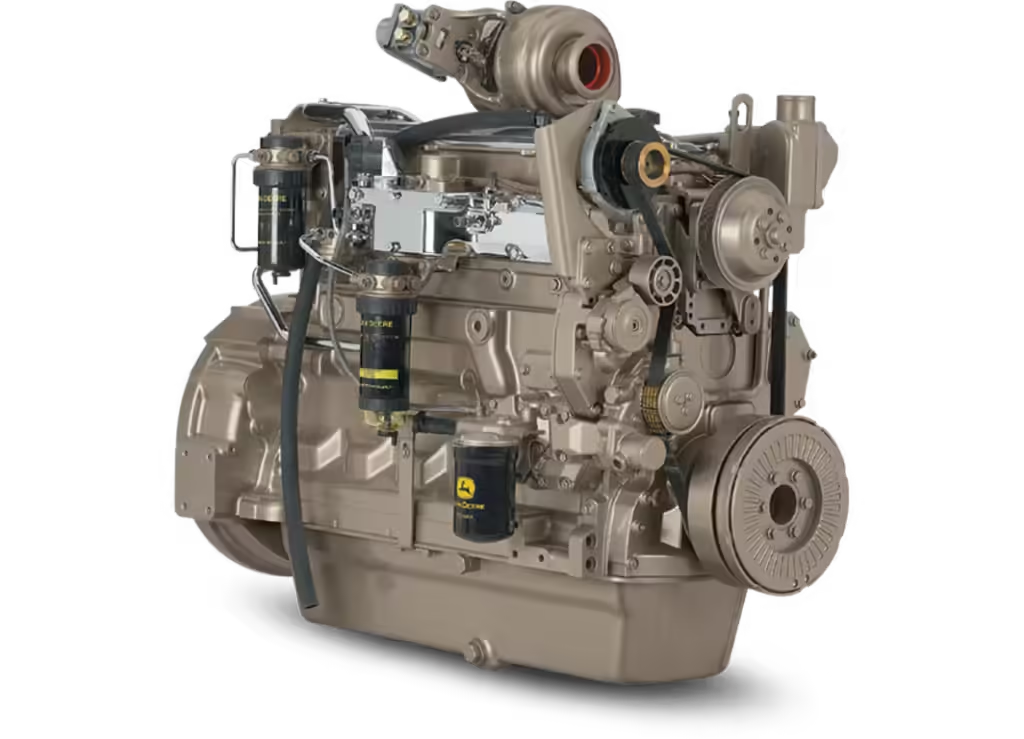

John Deere Engine 16 - 4045TF285 Variable Speed Industrial Auxiliary Engine

The 4045TF285 4.5L PowerTech™ is a variable speed engine for launches, work boats, trawler yachts, and patrol craft. With 74 kW (99 hp) power rating, these engines are perfect for light operations in smaller crafts.

Key Features

2-valve cylinder head

Cross flow head design that provides excellent breathing from a lower cost two-valve cylinder head

High-pressure common-rail (HPCR) and engine control unit (ECU)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures, up to 1600 bar (23,000 psi). It also controls fuel injection timing and provides precise control for the start, duration, and end of the injection.

Fixed geometry turbocharger

Fixed geometry turbochargers are sized for a specific power range and optimized to provide excellent performance across the entire torque curve. They are also designed to maximize fuel economy between the engine’s rated speed and peak torque.

Turbocharged

In turbocharged engines, the air is pre-compressed. Due to the higher pressure, more air is supplied into the combustion chamber allowing a corresponding increase in fuel injection which results in greater engine output.

Multiple injection strategy

The HPCR fuel system and engine control unit (ECU) allow for multiple fuel injections. The number of fuel injections, based on speed and load, help contribute to lower combustion temperatures, which reduce the formation of NOx and particulates. The multiple injection strategy also provides an added benefit of noise reduction.

John Deere electronic engine controls

PowerTech E engines offer electronically controlled fuel systems with improved cold-start performance, precise engine speed control, torque curve shaping and more. Because these systems have less need for redundant sensors, add-on electronic governors, and shutdown devices – they result in a lower total installed cost.

Additional features

- Self-adjusting poly-vee fan drive

- Forged-steel connecting rods

- Replaceable wet-type cylinder liners

- Either-side service

- 500-hour oil change

- Standard gear auxiliary drive

Emissions Certifications

EPA Marine Tier 3

Technical Specifications

General Engine Data

Model | 4045TF285 |

Number of cylinders | 4 |

Displacement– L (cu in) | 4.5 (275) |

Bore and Stroke– mm (in) | 106 x 127 (4.17 x 5.00) |

Engine Type | In-line, 4-Cycle |

Aspiration | Turbocharged |

Engine Dimensions

Length – mm (in) | 867 (34.1) |

Width Maximum – mm (in) | 680 (26.8) |

Height – mm (in) | 1055 (41.5) |

Weight, dry – kg (lb) | 491 (1082) |

Performance Data Range

Heavy Duty – Rated power/Rated speed | 63.6 kW (85 hp) @2200 rpm |

Heavy Duty – Peak power | 65 kW (87 hp) @2000 rpm |

Heavy Duty – Power bulge | 3 % @1900 rpm |

Heavy Duty – Peak torque | 354 N·m (261 ft-lb) @1600 rpm |

Heavy Duty – Torque rise | 29% |

John Deere Engine 17 - 6068HF485 Variable Speed Industrial Auxiliary Engine

This 6.8L PowerTech™ engine supports medium to heavy duty watercrafts at 187 kW (251 hp) power rating. With variable speed setting support, vessel owners have more power to control speed range depending on the electrical load for best fuel economy.

Key Features

4-valve cylinder head

The 4-valve cylinder head provides excellent airflow resulting in greater low-speed torque and better transient response. Cross flow design.

High-pressure common-rail (HPCR) and engine control unit (ECU)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures, up to 1600 bar (23,000 psi). It also controls fuel injection timing and provides precise control for the start, duration, and end of the injection.

Cooled exhaust gas recirculation (EGR)

EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing NOx.

Variable geometry turbocharger (VGT)

Varies exhaust pressure based on load and speed to ensure proper EGR flow; greater low-speed torque, quicker transient response, higher peak torque, and best-in-class fuel economy.

Air-to-air aftercooled

This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

John Deere electronic engine controls

- Electronic engine controls monitor critical engine functions, providing warning and/or shutdown to prevent costly engine repairs and eliminate the need for add-on governing components all lowering total installed costs. Snapshot diagnostic data that can be retrieved using commonly available diagnostic service tools.

- Controls utilize common wiring interface connector for vehicles or available OEM instrumentation packages; solid conduit and “T” connectors to reduce wiring stress and provide greater durability and improved appearance.

- Factory-installed, engine mounted ECU or remote-mounted ECU comes with wiring harness and associated components. Industry-standard SAE J1939 interface communicates with other vehicle systems, eliminating redundant sensors and reducing vehicle installed cost.

Additional features

- Glow plugs

- Gear-driven auxiliary drives

- Self-adjusting poly-vee

- Fan drive: and either-side service

Emissions Certifications

EPA Commercial Marine Tier 3

Technical Specifications

Model | 6068HF485 |

Number of cylinders | 6 |

Displacement– L (cu in) | 6.8 (415) |

Bore and Stroke– mm (in) | 106 x 127 (4.17 x 5.00) |

Compression Ratio | 17.0 : 1 |

Engine Type | In-line, 4-Cycle |

Aspiration | Turbocharged and air-to-air aftercooled |

Engine Dimensions

Length – mm (in) | 1161 (45.7) |

Width Maximum – mm (in) | 616 (24.3) |

Height – mm (in) | 1128 (44.4) |

Weight, dry – kg (lb) | 678 (1495) |

Performance Data Range

Heavy Duty – Rated power/Rated speed | 149 kW (200 hp) @ 2200 rpm |

Heavy Duty – Peak power | 168 kW (225 hp) @ 1800 rpm |

Heavy Duty – Power bulge | 13 % @ 1800 rpm |

Heavy Duty – Peak torque | 934 N·m (689 ft-lb) @ 1400 rpm |

Heavy Duty – Torque rise | 44% |

John Deere Engine 18 - 6090HF485 Variable Speed Industrial Auxiliary Engine

This 9.0L PowerTech™ engine is designed for commercial and recreational applications, including pleasure crafts, launches, work boats, fishing boats, trawler yachts, and sportfishing boats. It offers variable speed settings at 280 kW (375 hp) @2200 rpm.

Key Features

4-valve cylinder head

The 4-valve cylinder head, with U-flow head design, provides excellent airflow resulting in greater low-speed torque and better transient response.

High-pressure common-rail (HPCR) and engine control unit (ECU)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures, up to 1600 bar (23,000 psi). It also controls fuel injection timing and provides precise control for the start, duration, and end of the injection.

Cooled exhaust gas recirculation (EGR)

EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing NOx.

Variable geometry turbocharger (VGT)

Varies exhaust pressure based on load and speed to ensure proper EGR flow; greater low-speed torque, quicker transient response, higher peak torque, and best-in-class fuel economy.

Air-to-air aftercooled

This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

John Deere electronic engine controls

- Electronic engine controls monitor critical engine functions, providing warning and/or shutdown to prevent costly engine repairs and eliminate the need for add-on governing components all lowering total installed costs. Snapshot diagnostic data that can be retrieved using commonly available diagnostic service tools.

- Controls utilize common wiring interface connector for vehicles or available OEM instrumentation packages; solid conduit and “T” connectors reduce wiring stress and provide greater durability and improved appearance.

- Factory-installed, engine mounted ECU or remote-mounted ECU comes with wiring harness and associated components. Industry-standard SAE J1939 interface communicates with other vehicle systems, eliminating redundant sensors and reducing vehicle installed cost.

Additional features

- Gear-driven auxillary drives

- Self-adjusting poly-vee fan drive

- Single-piece low friction piston

- Optional rear PTO

- Low-pressure fueling system with “auto-prime” feature

- Directed top-liner cooling

Emissions Certifications

EPA Marine Tier 3

Technical Specifications

General Engine Data

Model | 6090HF485 |

Number of cylinders | 6 |

Displacement– L (cu in) | 9 (549) |

Bore and Stroke– mm (in) | 118.4 x 136.0 (4.66 x 5.35) |

Compression Ratio | 16.0 : 1 |

Engine Type | In-line, 4-Cycle |

Aspiration | Turbocharged and air-to-air aftercooled |

Engine Dimensions

Length – mm (in) | 1208 (47.6) |

Width Maximum – mm (in) | 630 (24.8) |

Height – mm (in) | 1113 (43.8) |

Weight, dry – kg (lb) | 901 (1986) |

Performance Data Range

Intermittent – Rated power/Rated speed | 280 kW (375 hp) @2200 rpm\ |

Intermittent – Peak power | 280 kW (375 hp) @2200 rpm |

Intermittent – Power bulge | 0 % |

Intermittent – Peak torque | 1543 N·m (1138 ft-lb) @1500 rpm |

Intermittent – Torque rise | 27% |

John Deere Engine 19- 6090HFM85 Variable Speed Industrial Auxiliary Engine

This 9.0L PowerTech™ engine is an excellent option for variable speed auxiliary applications in patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats. It offers 242 kW (325 hp) power rating running @ 2000 rpm speed.

Key Features

ABS type approved for use on classed & inspected vessels

- Water-cooled exhaust manifold and turbo to meet surface temperature requirements

- Marine Classification Society approved fuel hoses, lube and oil hoses

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in greater low-speed torque and better transient response.

- Cross flow design

Electronic unit injector (EUI) and engine control unit (ECU)

The EUI fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures, up to 2000 bar (29,000 psi). It also controls fuel injection timing and provides precise control for start, duration, and end of injection.

Air-to-air aftercooled

This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

John Deere electronic engine controls

- Electronic engine controls monitor critical engine functions, providing warning and/or shutdown to prevent costly engine repairs and eliminate the need for add-on governing components all lowering total installed costs. Snapshot diagnostic data that can be retrieved using commonly available diagnostic service tool.

- Controls utilize common wiring interface connector for vehicles or available OEM instrumentation packages; new solid conduit and “T” connectors to reduce wiring stress and provide greater durability and improved appearance.

- Factory-installed, engine mounted ECU and wiring harness and associated components. Industry- standard SAE J1939 interface communicates with other vehicle systems, eliminating redundant sensors and reducing vehicle installed cost.

Additional features

- Gear-driven auxiliary drives

- Self-adjusting poly-vee fan drive

- Single-piece low friction piston

- Low-pressure fuel system with “auto-prime” feature

- Directed top-liner cooling

Classification Societies

ABS

Emissions Certifications

- EPA Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 6090HFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 9.0 (549) |

Bore and Stroke– mm (in) | 118.4 x 136 (4.66 x 5.35) |

Engine Type | In-line, 4-cycle |

Aspiration | Turbocharged and Aftercooled |

Engine Dimensions

Length – mm (in) to rear of block | 1081 (42.6) |

Width Maximum – mm (in) | 714 (28.1) |

Height – mm (in) | 965 (38.0) |

Weight, dry – kg (lb) | TBD (TBD) |

Performance Data Range

Application Ratings | Variable Speed |

Rated Power | 242 kW (325 hp) @ 2000 rpm |

Rated torque | 1155 Nm (852 ft-lb) @ 2000 rpm |

Peak Torque | 1386 Nm (1022 ft-lb) @ 1500 rpm |

John Deere Engine 20 - 6135HF485 Variable Speed Industrial Auxiliary Engine

6135HF485 13.5L PowerTech™ is a powerful engine for variable speed auxiliary applications such as patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats. It offers 448 kW (600 hp) @ 2100 rpm.

Key Features

4-valve cylinder head

The 4-valve cylinder head provides excellent airflow resulting in greater low-speed torque and better transient response. Cross flow design.

Electronic unit injectors (EUI) and engine control unit (ECU)

The EUI fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures, up to 2000 bar (29,000 psi). It also controls fuel injection timing and provides precise control for start, duration, and end of injection.

Cooled exhaust gas recirculation (EGR)

EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing NOx.

Variable geometry turbocharger (VGT)

- Varies exhaust pressure based on load and speed to ensure proper EGR flow

- Greater low-speed torque, quicker transient response, higher peak torque, and best-in-class fuel economy.

Air-to-air aftercooled

This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

John Deere electronic engine controls

- Electronic engine controls monitor critical engine functions, providing warning and/or shutdown to prevent costly engine repairs and eliminate the need for add-on governing components all lowering total installed costs. Snapshot diagnostic data that can be retrieved using commonly available diagnostic service tools.

- Controls utilize common wiring interface connector for vehicles or available OEM instrumentation packages.

- Solid conduit and “T” connectors to reduce wiring stress and provide greater durability and improved appearance.

- Factory-installed, engine mounted ECU or remote-mounted ECU comes with wiring harness and associated components. Industry-standard SAE J1939 interface communicates with other vehicle systems, eliminating redundant sensors and reducing vehicle installed cost.

Additional features

- Gear-driven auxiliary drives

- 500-hour oil change

- Self-adjusting poly-vee fan drive

- Either-side service

- Single-piece low friction piston

- Optional rear PTO

- Low-pressure fuel system with “auto-prime” feature

- Directed top-liner cooling

Emissions Certifications

EPA Marine Tier 3

Technical Specifications

General Engine Data

Model | 6135HF485 |

Number of cylinders | 6 |

Displacement– L (cu in) | 13.5 (824) |

Bore and Stroke– mm (in) | 132 x 165 (5.20 x 6.50) |

Compression Ratio | 16.0:1 |

Engine Type | In-line, 4-Cycle |

Aspiration | Turbocharged and air-to-air aftercooled |

Engine Dimensions

Length – mm (in) | 1334 (52.5) |

Width Maximum – mm (in) | 855 (33.7) |

Height – mm (in) | 1512 (59.5) |

Weight, dry – kg (lb) | 1493 (3291) |

Performance Data Range

Intermittent – Rated power/Rated speed | 448 kW (601 hp) @2100 rpm |

Intermittent – Peak power | 448 kW (601 hp) @2100 rpm |

Intermittent – Power bulge | 0 % |

Intermittent – Peak torque | 2550 N·m (1881 ft-lb) @1275 rpm |

Intermittent – Torque rise | 25% |

John Deere Engine 21 - 6135HFM85 Variable Speed Industrial Auxiliary Engine

6135HFM85 13.5L PowerTech™ has variable speed industrial auxiliary configuration for powering patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats. This model offers 373 kW (500 hp) power output @ 2000 rpm.

Key Features

ABS type approved for use on classed & inspected vessels

- Water-cooled exhaust manifold and turbo to meet surface temperature requirements

- Marine Classification Society approved fuel hoses, lube, and oil hoses

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in greater low-speed torque and better transient response.

- Cross flow design

Electronic unit injector (EUI) and engine control unit (ECU)

The EUI fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures, up to 2000 bar (29,000 psi). It also controls fuel injection timing and provides precise control for start, duration, and end of injection

Air-to-air aftercooled

This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs

John Deere electronic engine controls

- Electronic engine controls monitor critical engine functions, providing warning and/or shutdown to prevent costly engine repairs and eliminate the need for add-on governing components all lowering total installed costs. Snapshot diagnostic data that can be retrieved using commonly available diagnostic service tools

- Controls utilize common wiring interface connector for vehicles or available OEM instrumentation packages; new solid conduit and “T” connectors to reduce wiring stress and provide greater durability and improved appearance

- Factory-installed, engine mounted ECU and wiring harness and associated components. Industry- standard SAE J1939 interface communicates with other vehicle systems, eliminating redundant sensors and reducing vehicle installed cost

Additional features

- Gear-driven auxiliary drives

- Self-adjusting poly-vee fan drive

- Single-piece low friction piston

- Low-pressure fuel system with “auto-prime” feature

- Directed top-liner cooling

Classification Societies

ABS

Emissions Certifications

- EPA Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

General Engine Data

Model | 6135HFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 13.5 (824) |

Bore and Stroke– mm (in) | 132 x 165 (5.20 x 6.50) |

Engine Type | In-line, 4-cycle |

Aspiration | Turbocharged and air-to-air aftercooled |

Engine Dimensions

Length – mm (in) to rear of block | 1225 (48.2) |

Width Maximum – mm (in) | 838 (33.0) |

Height – mm (in) | 1430 (56.3) |

Weight, dry – kg (lb) | 1322 (2914) |

Performance Data Range

Application Ratings | Variable Speed |

Rated Power | 373 kW (500 hp) @ 2000 rpm |

Rated torque | 1781 Nm (1314 ft-lb) @ 2000 rpm |

Peak Torque | 2137 Nm (1576 ft-lb) @ 1500 rpm |