Brand & Engine

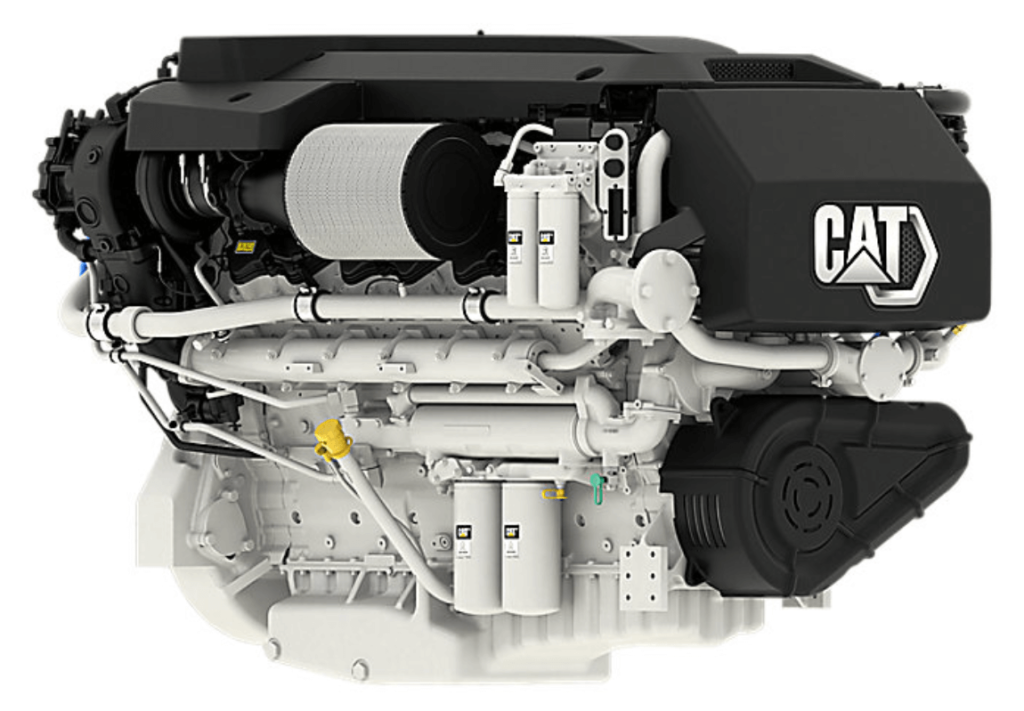

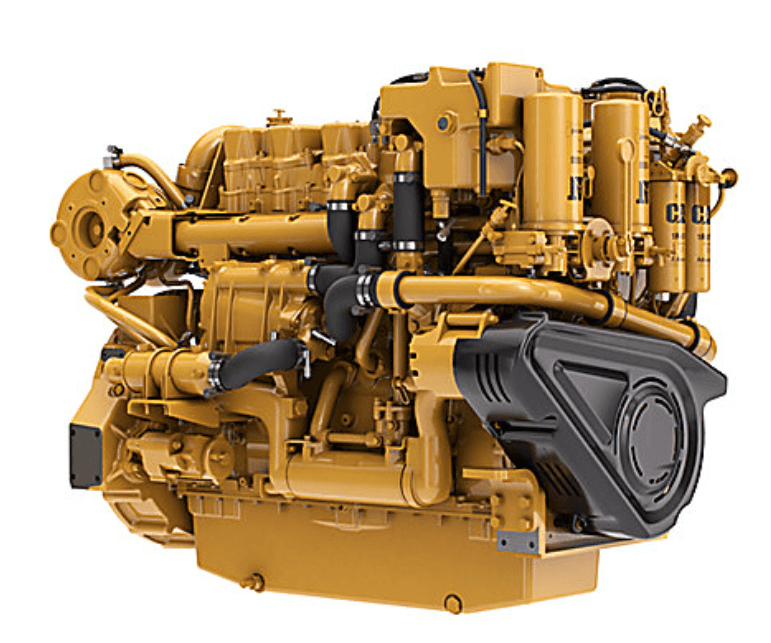

Caterpillar Engine 26 – High Performance Propulsion and Maneuvering Solutions C32B

KEY SPECS

Power Range

1800-2400 bhp (1342-1790 bkW)

Speed Range

2300 rpm

Emissions

IMO II, U.S. EPA Tier 3 (recreational), RCD, China II

Overview

With the introduction of the C32B product line in 2021, Caterpillar Marine now confirms the availability of the uprated Cat® C32B Marine Propulsion engine in 2025 mhp and 2433 mhp offerings. With 25% more peak power and high performance, this engine demonstrates great performance and efficiency, while also delivering noise reduction at lower engine speeds. This product meets IMO II and U.S. EPA Tier 3 (recreational) emissions standards and is perfectly suited for yachting applications. Governmental applications can also be a great fit for D-tier ratings. Please consult with your Cat Marine dealer regarding the use of E-tier ratings.

Key Features and Benefits:

- Updated engine design to enable higher power density

- Noise reduction at low engine speeds (MEUI-C Fuel System)

- Updated engine electronic control module (ADEM VI)

- MCS certifications available

- Updated seawater aftercooler and HEX design

- Optimized sequential air system maximizes performance and torque range

- LH and RH service side options available

- No zinc anodes required (use vessel bonding system)

PRODUCT SPECIFICATIONS FOR C32B

RATINGS

Power Range | 1800-2400 bhp (1342-1790 bkW) |

ENGINE

Speed Range | 2300 rpm |

Emissions | IMO II, U.S. EPA Tier 3 (recreational), RCD, China II |

Aspiration | Sequential Turbocharged – aftercooled |

Bore | 5.71 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | VEE 12, 4-Stroke Cycle diesel |

Flywheel Housing | SAE No. O |

Cooling | SWAC (Seawater Aftercooler) |

Governor | Electronic (ADEM VI) |

Oil Change Interval | 250 hrs |

Refill Capacity | Lube Oil System w/ oil filter change: 76 L (20 gal) |

DIMENSIONS & WEIGHTS

Dry Weight | 7736 lb |

Length | 87.8 in |

Width | 58 in |

Height | 58.1 in |

C32B STANDARD EQUIPMENT

STANDARD EQUIPMENT

- ADEM VI Electronic Control Module

- Air Cleaner / Closed Crankcase Ventilation

- Front and Rear Seawater Pumps

- Sea Water Aftercooler

- Titanium Plate Heat Exchanger

- Gear-driven JW and SW pumps

- Water-cooled Exhaust Manifolds and Turbochargers

- MEUI-C Fuel System

- 250-hr Oil Pan (Shallow Sump)

- RH or LH Service Side Options

C32B OPTIONAL EQUIPMENT

OPTIONAL ATTACHEMENTS

- 120V or 240V Jacket Water Heater

- SAE A or B PTO (RH rear)

- 75A, 105A or 175A Alternator

- Heat Shielding

- Cosmetic Engine Cover

- Electric Fuel Priming Pump

- Duplex Lube Oil and Fuel Filters

- Deep Sump Oil Pan

- Marine Alarm & Protection

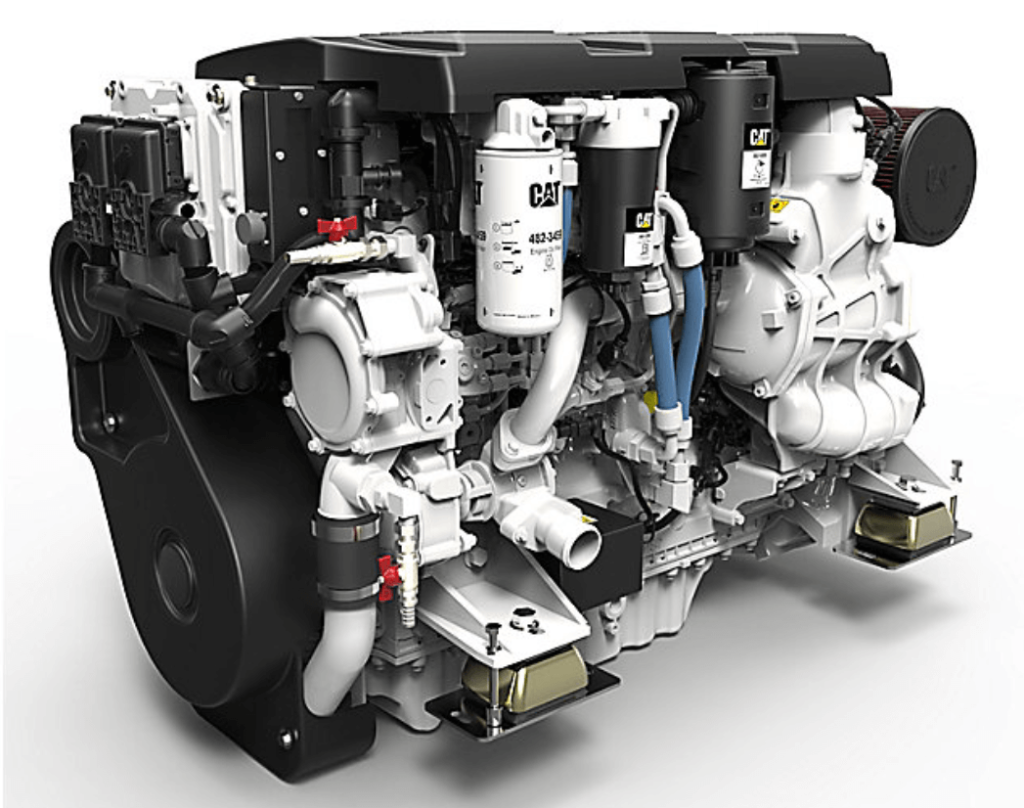

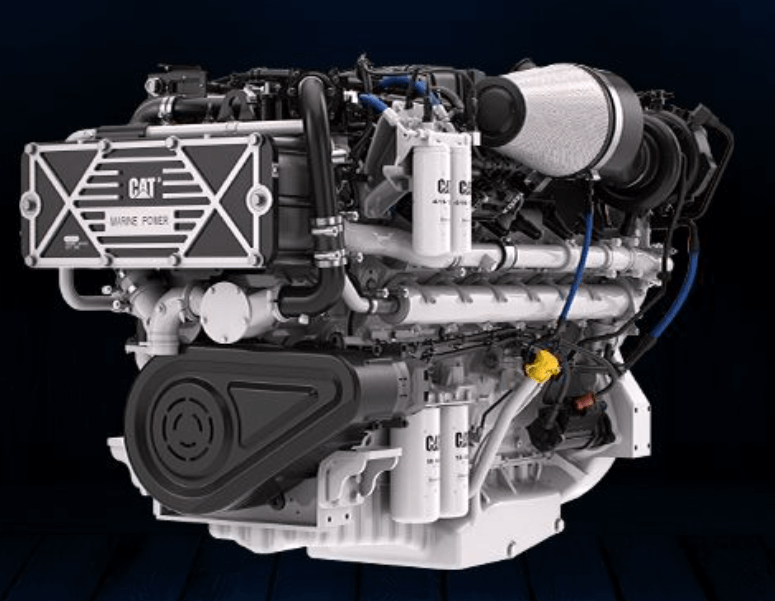

Caterpillar Engine 27 – High Performance Propulsion and Maneuvering Solutions C7.1

KEY SPECS

Power Range

400 bhp – 500 bhp (298 bkW – 373 bkW)

Speed Range

2900 rpm

Emissions

IMO II, U.S. EPA Tier 3, RCD II, China II

Overview

The C7.1 marine propulsion engine is ideal for recreational boating applications, specifically smaller vessels and motoryachts ranging from 25 -60 feet in size. The engine features a common rail fuel system enabling optimum combustion and low emissions. The engines provide noticeably quiet operation due to reduced combustion noise through advanced electronic control. Additionally, no visible smoke is emitted from the C7.1 engines during operation.

Key Features & Benefits

- Common rail fuel system enables optimum combustion and low emissions

- Reduced combustion noise through advanced electronic control

- 12V or 24V electrical system

- Compatible with Cat® displays and electronics

- Closed crankcase ventilation system improves engine room cleanliness

- Gear-driven jacket water pump and sea water pump for superior reliability

- Maintenance free valve train with hydraulic valve lash adjusters

- Self-priming fuel system ensures a smooth start every time

PRODUCT SPECIFICATIONS FOR C7.1

RATINGS

Power Range | 400 bhp – 500 bhp (298 bkW – 373 bkW) |

ENGINE SPECIFICATIONS

Speed Range | 2900 rpm |

Emissions | IMO II, U.S. EPA Tier 3, RCD II, China II |

Rotation from Flywheel End | Counterclockwise |

Bore | 4.13 in |

Stroke | 5.31 in |

Aspiration | Turbocharged, aftercooled |

Displacement | 428 in³ |

Configuration | In-line 6, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Width – Engine | 31.4 in |

Height | 34.5 in |

Engine Dry Weight – Approximate | 1676 lb |

Length – Engine | 43.1 in |

C7.1 STANDARD EQUIPMENT

STANDARD EQUIPMENT

- Water cooled turbocharger and exhaust manifold

- Common rail fuel system

- Corrosion resistant sea water aftercooler

- Closed crankcase ventilation system

- Starter motors – 12V or 24V

- Fuel cooler

- Integral engine oil cooler

- Vibration damper and guard

- Electric fuel priming pump

- Self-tensioning multi-vee alternator drive belt

- Gear driven sea water pump (rubber impeller)

- Fin and tube type jacket water heat exchanger

- Front and rear engine mounting brackets

C7.1 OPTIONAL EQUIPMENT

OPTIONAL ATTACHEMENTS

- Alternators – 24V 140 amp – 12V 175 amp

- Transmission gear oil cooler (engine mounted)

- Instrument Panels

- Glow plugs

- Jacket water heater

- 6″ water cooled exhaust elbow

- Isolation mounts

- Primary fuel filter/water separator (remote mount)

- Selection of factory-fitted marine transmissions and oil hoses

- Cabin heater (calorifier) connections

- Triple groove PTO pulley (crankshaft mounted)

- Flexible fuel hoses

- Right-hand and high level left hand oil dipsticks

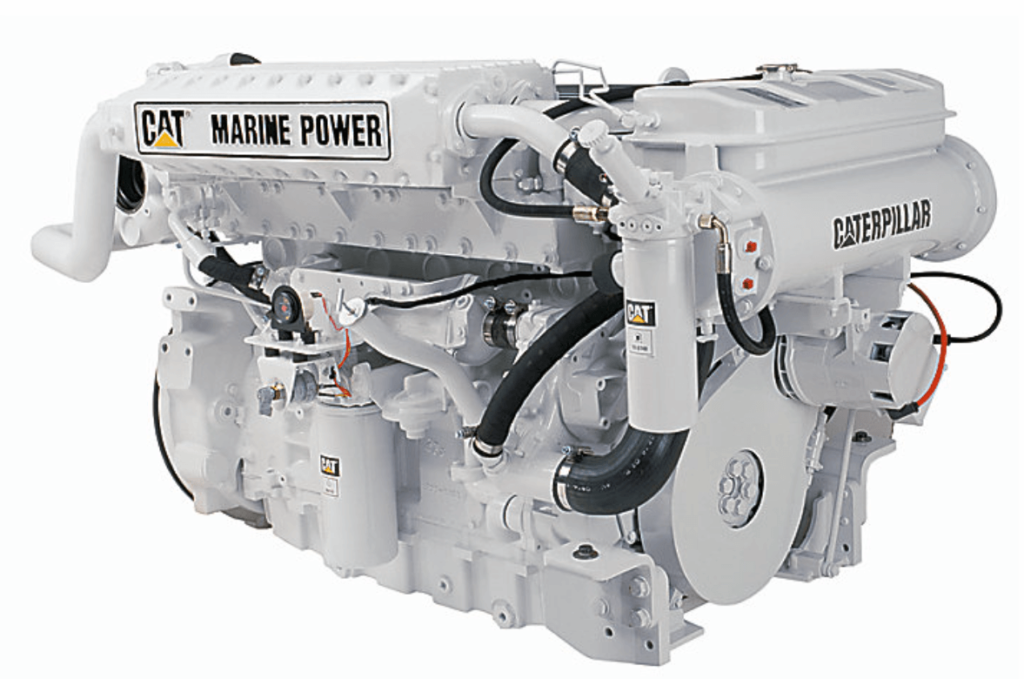

Caterpillar Engine 28 – High Performance Propulsion and Maneuvering Solutions C12

KEY SPECS

Power Range

578-609 mhp (570-600 bhp)

Speed Range

2300 rpm

Emissions

IMO I

Overview

Cat® C12 Diesel Marine Propulsion Engines, with ratings of 578-609 mhp (570-600 bhp) at 2300 rpm, meet IMO I emission standards. The C12 takes full advantage of the electronically controlled unit injection fuel system, resulting in an environmentally friendly engine with outstanding performance and fuel economy. There is also a wide range of optional equipment available to meet the needs of your marine commercial or pleasure craft application.

Key Features

- Adem Iii Control System: More control inputs and outputs, capacity for additional features, additional monitoring capabilities, expansion capability for future enhancements

- Most Advanced Electronic Control System: Adjustment free control of engine speed, customer defined operating characteristics, protection and warning system, optional display systems available

- Future Enhancement Capability: The electronic control system has additional capacity for future enhancements to ensure a long useful engine life

- Redesigned Exhaust Manifold: Provides a smoother passage for improved exhaust gas flow to the turbocharger which leads to more usable energy and lower exhaust temperatures.

- Easy Replacement for 3196: The C12 has the same physical size, same footprint, and the same connection points as the 3196 engine as well the same optional attachments.

- Optional Monitoring System: Caterpillar offers several “plug and play” monitoring systems which display everything from the basic engine operating parameters to engine load factor and trip totals. Ask your local Caterpillar dealer for additional information on our Marine Power Display (MPD), Marine Analog Power Display (MAPD), and our Engine Vision Display (EVD).

- Product Support: Trained technicians at over 1800 authorized service locations worldwide support Caterpillar products. Use our Internet Dealer Locator www.cat.com to identify the Caterpillar dealer location nearest to you.

- Warranty: C-12 Marine Propulsion engines used in commercial applications are covered for 12 months from the date of delivery to the end user. Engines used in non-revenue producing pleasure craft applications are covered for 24 months, unlimited hours, from the date of delivery. Concurrently, specific engine components are covered for 60 months, unlimited hours, from the date of delivery to the end user.

- Extended Service Coverage (esc): Optional engine protection coverage for up to 60 months from date of delivery may be purchased through your local Caterpillar dealer.

PRODUCT SPECIFICATIONS FOR C12

RATINGS

Power Range | 578-609 mhp (570-600 bhp) |

ENGINE

Speed Range | 2300 rpm |

Emissions | IMO I |

Aspiration | TA |

Bore | 5.1 in |

Stroke | 5.9 in |

Displacement | 732 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | In-line 6, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Height | 39.5 in |

Length | 62 in |

Width | 38.1 in |

Dry Weight | 2588 lb |

C12 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler – sea water; corrosion resistant, Air Cleaner/Fumes Disposal (closed system), Turbocharger, Jacket Water Cooled

CONTROL SYSTEM

- Electronic governing, Cold mode start strategy, Power compensation for fuel temperature, Programmable low idle, Electronic diagnostics and fault logging, Engine and transmission monitoring (speed, temperature, pressure), Fuel/air ratio control, Emergency stop switch (A&B ratings only)

COOLING SYSTEM

- Thermostat and housing, Jacket water pump; gear driven, Sea water pump; rubber impeller; self-priming; gear-driven, Integral heat exhanger/expansion tank; removable tube bundle; replaceable copper-nickel tubes, Keel cooling – combined circuit (includes pipe thread flange kit)

EXHAUST SYSTEM

- Watercooled Manifold & Turbocharger

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel; SAE No. 1; 113 teeth, Flywheel housing; SAE No. 1 (10 degree slant pad), SAE standard rotation

FUEL SYSTEM

- Fuel filer; RH service on Port; LH service on Starboard, Fuel transfer pump, Fuel priming pump, Flexible fuel lines

INSTRUMENTATION

- Service meter, electric

LUBE SYSTEM

- Crankcase breather, Oil cooler, Oil filter; spin-on; RH service on Port; LH service on Starboard, Oil filler, Dipstick; RH service on Port; LH service on Starboard, Oil pump; gear driven

MOUNTING SYSTEM

- Front support

POWER TAKE-OFFS

- Hydraulic pump drive; SAE A; 11 tooth spline, 57 ft-lbs max torque; counterclockwise as viewed from the rear of hte engine looking into the pump drive and turns 1.41 x engine speed, Crankshaft pulley; 345 mm (13.6 in) single groove; 15.88 mm (.63in) width

PROTECTION SYSTEM

- Shutdown; electronic; 12 or 24 volt; energized to run

GENERAL

- Vibration damper, Lifting eyes, RH or LH service options, Literature, Variable engine wiring, Upper rear-facing customer wiring connector and ECAP connection, Electronic installation kit (connectors, pins, sockets)

C12 OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Low Profile Air Inlet Line, Shield (Air Inlet Line)

CHARGING SYSTEM

- Charging Alternators, Voltmeter Guages, Voltmeter Guage Mounting, Alternator Mounting Group

COOLING SYSTEM

- Sea Water Pump, Coolant Recovery Tank, Flange Kit

EXHAUST SYSTEM

- Flexible Fitting, Elbow, Dry Elbow, Watercooled Elbow, Exhaust Connection, Exhaust Outlet Pipe, EXH Outlet Flange, Rain Cap, Muffler

FUEL SYSTEM

- Fuel Cooler, Fuel Connections, Primary Fuel Filter, Primary Fuel/Water Separator

INSTRUMENTATION

- OEM Wiring Harness, Engine to Engine Harness, Digital Tachometer, Tachometer Mounting, Magnetic Pickup, RH 4 Hole Instrument Panel, LH 4 Hole Instrument, Marine Power Display System, Marine Power Display Unit (for additional monitoring stations), Marine Power Display Bracket, Wiring Group, Transmission Sensors

LUBE SYSTEM

- Manual sump pump, Transmission oil cooler

MOUNTING SYSTEM

- Vibration Isolators

POWER TAKE-OFFS

- Crankshaft Pulley, Front Stub Shaft, Front Stub Shaft & Pulley

STARTING SYSTEM

- Air Pressure Regulator, Air Start Silencer, Start Switch, Jacket Water Heater, Battery sets (24 volt – dry)

GENERAL

- Wiring Harness Removal, Belt Guard – Alternator, Belt Guard – Alternator Pulley, Filter Cover Kit

PACKING

- Overseas Preservation, Engine Protective Cover, Storage Preservation, Export Packing

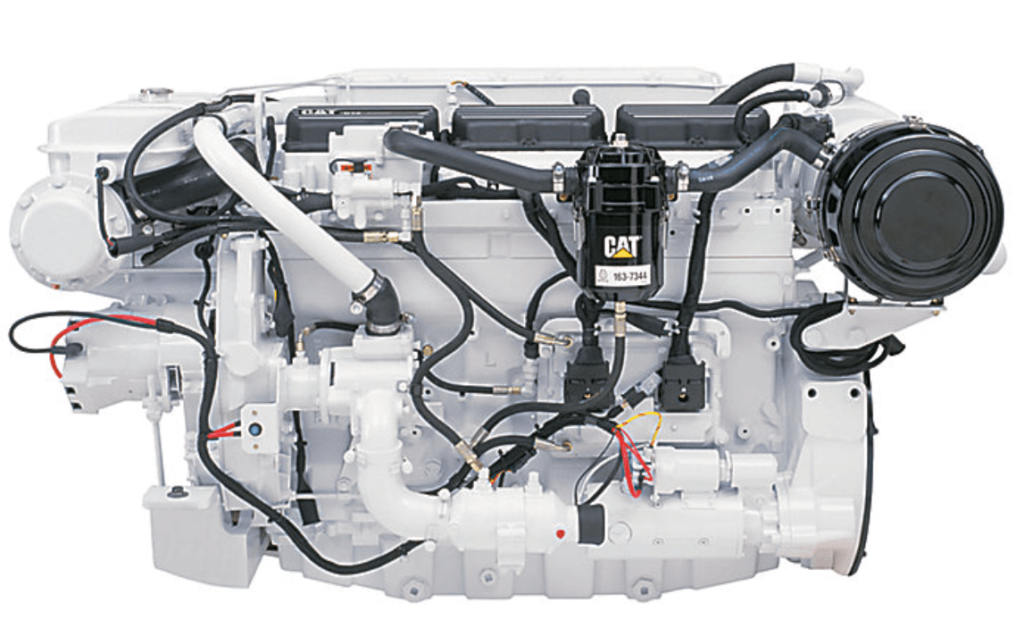

Caterpillar Engine 29 – High Performance Propulsion and Maneuvering Solutions C12 ACERT

KEY SPECS

Power Range

660-705 bhp (492-526 bkW)

Speed Range

2300 rpm

Emissions

IMO II

Overview

Cat® C12 ACERT Diesel Marine Propulsion Engines, with ratings of 669-715 mhp (660-705 bhp) at 2300 rpm, meet IMO II emission standards. The C12 takes full advantage of the electronically controlled unit injection fuel system, resulting in an environmentally friendly engine with outstanding performance and fuel economy. There is also a wide range of optional equipment available to meet the needs of your specific pleasure craft application.

Key Features

- Less Visible White or Black Smoke

- Lower Compression Ratio, Resulting in Less Steady State Smoke

- Improved Transient Response

- Standard Caterpillar Warranty

- Parts and Service Support from Worldwide Dealer Organization

PRODUCT SPECIFICATIONS FOR C12 ACERT

RATINGS

Power Range | 660-705 bhp (492-526 bkW) |

ENGINE

Speed Range | 2300 rpm |

Emissions | IMO II |

Aspiration | TA |

Bore | 5.1 in |

Stroke | 5.9 in |

Displacement | 732 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | In-line 6, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Width | 38.1 in |

Dry Weight | 2588 lb |

Length | 62 in |

Height | 39.5 in |

C12 ACERT STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler – sea water; corrosion resistant, Air Cleaner/Fumes Disposal (closed system), Turbocharger, Jacket Water Cooled

CONTROL SYSTEM

- Electronic governing, Cold mode start strategy, Power compensation for fuel temperature, Programmable low idle, Electronic diagnostics and fault logging, Engine and transmission monitoring (speed, temperature, pressure), Fuel/air ratio control, Emergency stop switch (A&B ratings only)

COOLING SYSTEM

- Thermostat and housing, Jacket water pump; gear driven, Sea water pump; rubber impeller; self-priming; gear-driven, Integral heat exhanger/expansion tank; removable tube bundle; replaceable copper-nickel tubes, Keel cooling – combined circuit (includes pipe thread flange kit)

EXHAUST SYSTEM

- Watercooled Manifold & Turbocharger

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel; SAE No. 1; 113 teeth, Flywheel housing; SAE No. 1 (10 degree slant pad), SAE standard rotation

FUEL SYSTEM

- Fuel filer; RH service on Port; LH service on Starboard, Fuel transfer pump, Fuel priming pump, Flexible fuel lines

LUBE SYSTEM

- Crankcase breather, Oil cooler, Oil filter; spin-on; RH service on Port; LH service on Starboard, Oil filler, Dipstick; RH service on Port; LH service on Starboard, Oil pump; gear driven

MOUNTING SYSTEM

- Front support

POWER TAKE-OFFS

- Hydraulic pump drive; SAE A; 11 tooth spline, 57 ft-lbs max torque; counterclockwise as viewed from the rear of hte engine looking into the pump drive and turns 1.41 x engine speed, Crankshaft pulley; 345 mm (13.6 in) single groove; 15.88 mm (.63in) width

PROTECTION SYSTEM

- Shutdown; electronic; 12 or 24 volt; energized to run

GENERAL

- Vibration damper, Lifting eyes, RH or LH service options, Literature, Variable engine wiring, Upper rear-facing customer wiring connector and ECAP connection, Electronic installation kit (connectors, pins, sockets)

C12 ACERT OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Low Profile Air Inlet Line, Shield (Air Inlet Line)

CHARGING SYSTEM

- Charging Alternators, Voltmeter Guages, Voltmeter Guage Mounting, Alternator Mounting Group

COOLING SYSTEM

- Sea Water Pump, Coolant Recovery Tank, Flange Kit

EXHAUST SYSTEM

- Flexible Fitting, Elbow, Dry Elbow, Watercooled Elbow, Exhaust Connection, Exhaust Outlet Pipe, EXH Outlet Flange, Rain Cap, Muffler

FUEL SYSTEM

- Fuel Cooler, Fuel Connections, Primary Fuel Filter, Primary Fuel/Water Separator

INSTRUMENTATION

- OEM Wiring Harness, Engine to Engine Harness, Digital Tachometer, Tachometer Mounting, Magnetic Pickup, RH 4 Hole Instrument Panel, LH 4 Hole Instrument, Marine Power Display System, Marine Power Display Unit (for additional monitoring stations), Marine Power Display Bracket, Wiring Group, Transmission Sensors

LUBE SYSTEM

- Manual sump pump, Transmission oil cooler

MOUNTING SYSTEM

- Vibration Isolators

POWER TAKE-OFFS

- Crankshaft Pulley, Front Stub Shaft, Front Stub Shaft & Pulley

STARTING SYSTEM

- Air Pressure Regulator, Air Start Silencer, Start Switch, Jacket Water Heater, Battery sets (24 volt – dry)

GENERAL

- Wiring Harness Removal, Belt Guard – Alternator, Belt Guard – Alternator Pulley, Filter Cover Kit

PACKING

- Overseas Preservation, Engine Protective Cover, Storage Preservation, Export Packing

Caterpillar Engine 30 – High Performance Propulsion and Maneuvering Solutions C18 ACERT TIER 3

KEY SPECS

Power Range

814-1015 mhp, 803-1001 bhp, 599-747 bkW

Speed Range

2100-2300 rpm

Emissions

EPA Tier 3, IMO II, EU Stage IIIA

Overview

The C18 ACERT marine propulsion engine has high performance commercial application ratings of 814-1015 mhp (803-1001 bhp) at 2100-2300 rpm that meet U.S. EPA Tier 3, IMO II, and EU Stage IIIA emissions regulations. In addition to meeting the stricter EPA Tier 3 emissions, this engine now offers a fresh water aftercooled option for the commercial propulsion and auxiliary engines and genset packages. From fishing to offshore and everything in between, you can be confident that we have the solution to fit your needs.

Key Features

- Separate Circuit Aftercooling System: The primary advantage of the separate circuit aftercooling system (SCAC) is that no sea water circulates through the aftercooler

- Emissions: EPA Tier 3 compliant, IMO II and EU IWW compliant

- Cooling System: Heat exchanger and Keel cooled options for all ratings

- Turbo Configurations: Single turbo configurations for all ratings

- Competitive Size and Weight:

- Marine Certifications: All major MCS type approvals available from factory

PRODUCT SPECIFICATIONS FOR C18 ACERT TIER 3

RATINGS

Power Range | 814-1015 mhp, 803-1001 bhp, 599-747 bkW |

ENGINE

Speed Range | 2100-2300 rpm |

Emissions | EPA Tier 3, IMO II, EU Stage IIIA |

Aspiration | TA,TTA |

Bore | 5.7 in |

Stroke | 7.2 in |

Displacement | 1106 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | In-line 6, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Maximum Length | 76 in |

Minimum Length | 73 in |

Maximum Dry Weight | 4299 lb |

Minimum Dry Weight | 4000 lb |

Maximum Height | 51.2 in |

Minimum Height | 47.2 in |

Maximum Width | 47.4 in |

Minimum Width | 44.6 in |

C18 ACERT TIER 3 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Open Crankcase Ventilation (OCV) system

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Engine JW and SCAC Shell & Tube Heat Exchangers for HEX cooled engines

- SCAC pump, gear driven, for HEX cooled engines only

- Jacket water pump, gear driven

- Sea water pump, bronze impeller, gear driven

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 152 mm (6 in) round flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

- SAE No. 1, Flywheel: 14 inch, 113 teeth

FUEL SYSTEM

- Front service simplex fuel system

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Front service simplex oil system

- Center sump oil pan:

- Front and top service oil filler locations

- Front service dipstick

- Oil pump, gear driven

POWER TAKE-OFFS

- Poly-V groove for alternator drive

- NOTE: There are no standard power take-offs available

GENERAL

- Front damper guard

- Front service engine

- Common electrical bonding point

- Engine does not ship with zinc components

- Engine is certified to D2/E2 emissions cycles

- CERTIFIED TO 2013 EPA TIER 3 AND IMO II MARINE COMMERCIAL PROPULSION (E3 CYCLE) EMISSION STANDARDS

- CERTIFIED TO EU STAGE IIIA AND CCNR STAGE II (E3 CYCLE) EMISSIONS STANDARDS.

- NOTE: Ratings listed below can also be used in Recreational / Pleasure Craft applications.

CONTROL SYSTEM

- Programmable low idle

- WOSR (Wide Operating Speed Range) available for EPA Tier 3 – B and C Ratings

- Adjustable High Idle (TEL) – EPA Tier 3 WOSR Ratings Only

- Electronic diagnostics and fault logging

- Engine and transmission monitoring (speed, temperature, pressure)

- Electronic fuel/air ratio contro

- Engine Protection Mode for extended ambient conditions – EPA Tier 3 Ratings Only

- Torque Limiting functionality for WOSR ratings only

- 70-pin customer connector

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA +/-

C18 ACERT TIER 3 OPTIONAL EQUIPMENT

EXHAUST SYSTEM

- Dry Elbows

- Water-Cooled Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- Alternator Mounting Group

- Ammeter

CONTROL SYSTEM

- MECP I

- CATERPILLAR ALARM AND PROTECTION

COOLING SYSTEM

- AUX EXPANSION TANK FLANGE KIT

FUEL SYSTEM

- Duplex Fuel Filters

- Flexible Fuel Lines

- Fuel Cooler

- Primary Fuel Filters

INSTRUMENTATION

- Instrument Panels

- OEM Wiring Harness

- Engine to Engine Harness

- Gauges

- Transmission Sensors

- Oil Level Sensor

LUBE SYSTEM

- Duplex Oil Filters

- Transmission Oil Cooler

- Sump Pump

MOUNTING SYSTEM

- Vibration Isolators

- Front Support

- Rear Support

POWER TAKE-OFFS

- NOTE: PTO OPTIONS REQUIRE TORSIONAL VIBRATION ANALYSIS

- Crankshaft Pulleys

- Front Stub Shaft

- Hydraulic Pump Drive Adapter

- Front Enclosed Clutch

PROTECTION SYSTEM

- Marine Classification Society and SOLAS

- Marine Classification Society and Fire Resistance

STARTING SYSTEM

- STARTING SYSTEM Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

Caterpillar Engine 31 – High Performance Propulsion and Maneuvering Solutions C18 ACERT TIER 3 RECREATIONAL

KEY SPECS

Power Range

1015-1150 mhp, 1001-1136 bhp, 747-847 bkW

Speed Range

2300 rpm

Emissions

EPA Tier 3, IMO II, EU IW

Overview

The C18 ACERT marine propulsion engine has ratings for recreational applications that meet U.S. EPA Tier 3, IMO II, and EU Stage IIIA Regulations. This marine engine incorporates the latest core engine system innovations to provide maximum benefits in power density, performance, emissions, and fuel efficiency. Not only is it equipped with engine monitoring and protection features, it is also compatible with Cat display and vessel control systems. With this engine comes the unmatched worldwide marine support network including Cat dealers and hundreds of authorized marine dealers. Their combined experience and expertise, products and services, backup and support allow your recreational pleasure craft to remain precisely that — a pleasure.

KEY FEATURES

- Separate Circuit Aftercooling System: The primary advantage of the separate circuit aftercooling system (SCAC) is that no sea water circulates through the aftercooler

- Emissions: EPA Tier 3 compliant, IMO II and EU IWW compliant

- Cooling System: Heat exchanger and Keel cooled options for all ratings

- Turbo Configurations: Single turbo configurations for all ratings

- Competitive Size and Weight:

- Marine Certifications: All major MCS type approvals available from factory

PRODUCT SPECIFICATIONS FOR C18 ACERT TIER 3 RECREATIONAL

RATINGS

Power Range | 1015-1150 mhp, 1001-1136 bhp, 747-847 bkW |

ENGINE

Speed Range | 2300 rpm |

Emissions | EPA Tier 3, IMO II, EU IW |

Aspiration | TA,TTA |

Bore | 5.7 in |

Stroke | 7.2 in |

Displacement | 1106 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | In-line 6, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Maximum Height | 51.2 in |

Minimum Height | 47.2 in |

Maximum Length | 76 in |

Minimum Length | 73 in |

Maximum Width | 47.4 in |

Minimum Width | 44.6 in |

Maximum Dry Weight | 4299 lb |

Minimum Dry Weight | 4000 lb |

C18 ACERT TIER 3 RECREATIONAL STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler – sea water, corrosion resistant

- Air cleaner/fumes disposal (closed system)

- Turbocharger, jacket water cooled

- Front-down and rear-down aftercooler condensate drains

CONTROL SYSTEM

- Electronic diagnostics and fault logging

- Cold mode start strategy

- Engine and transmission monitoring (speed, temperature, pressure)

- Electronic fuel/air ratio control

- 70-pin customer connector

- Engine Protection Mode for High Ambient Conditions

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA +/-)

COOLING SYSTEM

- Sea water pump, rubber impeller, self-priming, gear driven

- Sea water aftercooled

- Jacket water pump, gear driven

- JW Heat Exchanger – Titanium plate with integral fuel cooler expansion tank, and thermostat housing (fully open temp 92C)

- Coolant recovery system

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 114.3 mm (4.5 in) ID round flanged exhaust outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 1

- Flywheel, 18 inch, 113 teeth

- SAE standard rotation

FUEL SYSTEM

- Fuel filter, RH service on Port, LH service on Starboard

- Fuel transfer pump

- Fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Crankcase breather

- Oil cooler

- Oil filter, spin-on, low profile, RH service on Port, LH service on

- Oil pan, center sump

- Dipstick, RH service on Port, LH service on Starboard

- Oil pump, gear driven

POWER TAKE-OFFS

- Hydraulic pump drive, SAE A, 11-tooth spline, 46 ft-lbs max torque, counterclockwise as viewed from the front of the engine with 1.41 x engine speed

- Crankshaft pulley, 292 mm (11.5 in) two groove, 15.88 mm (0.63 in) width

PROTECTION SYSTEM

- A4 ECM Electronic Engine Monitoring System provides customer programmable engine de-rate strategies to protect against adverse operating conditions

GENERAL

- Front damper guard

- Lifting eyes

- RH or LH service options

- Upper rear-facing customer wiring connector and Service Tool connection

C18 ACERT TIER 3 RECREATIONAL OPTIONAL EQUIPMENT

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

FUEL SYSTEM

- Primary Fuel Filter / Water Separator

- Primary Fuel Filter

LUBE SYSTEM

- Transmission Oil Cooler

POWER TAKE-OFFS

- Crankshaft Pulleys

STARTING SYSTEM

- Electric Starting Motor – Single 24 Volt

- Battery Sets – 24 Volt – Dry

CONTROL SYSTEM

- MECP I

INSTRUMENTATION

- OEM Wiring Harness

- Engine to Engine Harness

- Instrument Panels

- Transmission Sensors

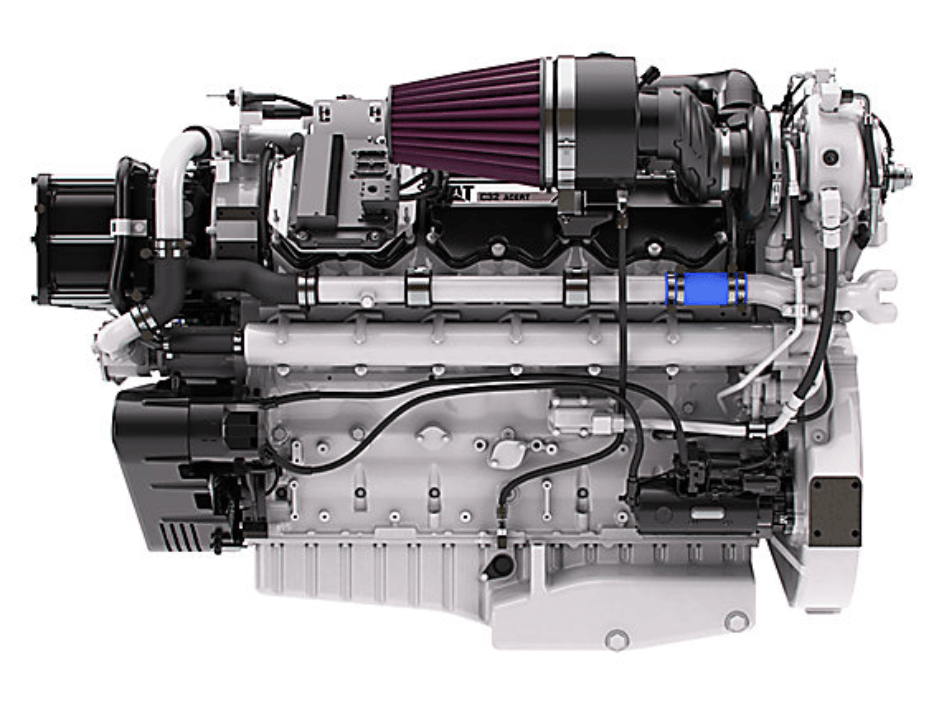

Caterpillar Engine 32 – High Performance Propulsion and Maneuvering Solutions C32B

KEY SPECS

Power Range

2000 bhp (1491 bkW)

Speed Range

2300 rpm

Emissions

IMO II, U.S. EPA Tier 3 Recreational, RCD, China Stage II

Overview

C32B Tier 3 Recreational

All new from the block up and built on the proven C32 platform, the C32B marine engine delivers more power, more speed, more time on the water and more peace of mind. All that comes in a quieter package with only a 2% increase in weight compared to the previous model — making the C32B the right choice for new builds and repowers. Rated at 2025 mhp (2000 bhp) / 1491 bkW @ 2300 rpm, the C32B meets U.S. EPA Marine Tier 3 and IMO II emissions standards. With an E Tier rating, it can run at the full 2000hp up to 8% of the time.

Key Features and Benefits:

- Electronically Governed and Controlled (ADEM VI ECM)

- Noise Reduction at low engine speeds (MEUI-C Fuel System)

- Improved Acceleration Capability

- Gear-driven Jacket Water Pump and Sea Water Pump for Enhanced Reliability

- MCS Certifications Available

- Titanium Plate Heat Exchanger

- LH and RH Service side options available

PRODUCT SPECIFICATIONS FOR C32B

RATINGS

Power Range | 2000 bhp (1491 bkW) |

ENGINE

Speed Range | 2300 rpm |

Emissions | IMO II, U.S. EPA Tier 3 Recreational, RCD, China Stage II |

Aspiration | TTA |

Bore | 5.71 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | Vee 12, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Width | 57.8 in |

Length | 82.9 in |

Height | 56.9 in |

Dry Weight | 9934 lb |

ENGINE SPECIFICATIONS

Stroke | 6.38 in |

C32B STANDARD EQUIPMENT

STANDARD EQUIPMENT

- ADEM VI Electronic Control Module

- Air Cleaner / Fumes Disposal

- Electronic Diagnostics and Fault Logging

- Engine and Transmission Monitoring

- Sea Water Aftercooler

- Titanium Plate Heat Exchanger with Expansion Tank

- Gear-driven JW and SW pumps

- Water-cooled Exhaust Manifolds and Turbochargers

- MEUI-C Fuel System

- Fuel Priming and Transfer Pump

- 250-hr Oil Pan (Shallow Sump)

- RH or LH Service Side Options

C32B OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- 120V or 240V Jacket Water Heater

- SAE A or B PTO (LH or RH rear)

- 75A or 105A Alternator

- Spray Shielding

Caterpillar Engine 33 – High Performance Propulsion and Maneuvering Solutions C32

KEY SPECS

Power Range

1600-1900 bhp (1193-1417 bkW)

Speed Range

2300 rpm

Emissions

IMO II, U.S. EPA Tier 3 Recreational, RCD, China Stage II

Overview

C32 propulsion engine ratings of 1925 mhp (1900 bhp) 1417 bkW, 1825 mhp (1800 bhp) 1342 bkW, and 1622 mhp (1600 bhp) 1193 bkW are available with heat exchanger cooling. These ratings are compliant for U.S. EPA Tier 3 Recreational, EU Stage IIIA, and IMO II. The 1600 and 1800 bhp ratings are also meet US EPA Tier 3 Commercial Standards. The engine configuration includes an air cleaner and CCV system as well as jacket water aftercooling. Additional features include a “plug-in PTO”, an MECP I control panel, and hybrid fuel lines. The MECP I panel has a monochrome display for engine parameters, external outputs for customer installed visible and audible alarms, Start/Stop buttons, and an Off/Local/Remote switch.

Key Features & Benefits

- Electronically Governed and Controlled (ADEM IV ECM)

- Gear-drive Jacket Water Pump and Sea Water Pump for Enhanced Reliability

- MCS Certifications Available

- Titanium Plate Heat Exchanger

- LH and RH Service side options available

PRODUCT SPECIFICATIONS FOR C32

RATINGS

Power Range | 1600-1900 bhp (1193-1417 bkW) |

ENGINE

Speed Range | 2300 rpm |

Emissions | IMO II, U.S. EPA Tier 3 Recreational, RCD, China Stage II |

Aspiration | Twin Turbocharged-aftercooled |

Bore | 5.71 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | Vee 12, 4-Stroke Cycle diesel |

DIMENSIONS & WEIGHTS

Length | 82.9 in |

Width | 58.3 in |

Height | 56.9 in |

Dry Weight | 6780 lb |

C32 STANDARD EQUIPMENT

STANDARD EQUIPMENT

- ADEM IV Electronic Control Module

- Air Cleaner / Fumes Disposal

- Electronic Diagnostics and Fault Logging

- Engine and Transmission Monitoring

- Sea Water Aftercooler

- Titanium Plate Heat Exchanger with Expansion Tank

- Gear-driven JW and SW pumps

- Water-cooled Exhaust Manifolds and Turbochargers

- MEUI Fuel System

- Fuel Priming and Transfer Pump

- 250-hr Oil Pan (Shallow Sump)

- RH or LH Service Side Options

C32 OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- 120V or 240V Jacket Water Heater

- SAE A or B PTO (LH or RH rear)

- 75A or 105A Alternator

- Spray Shielding

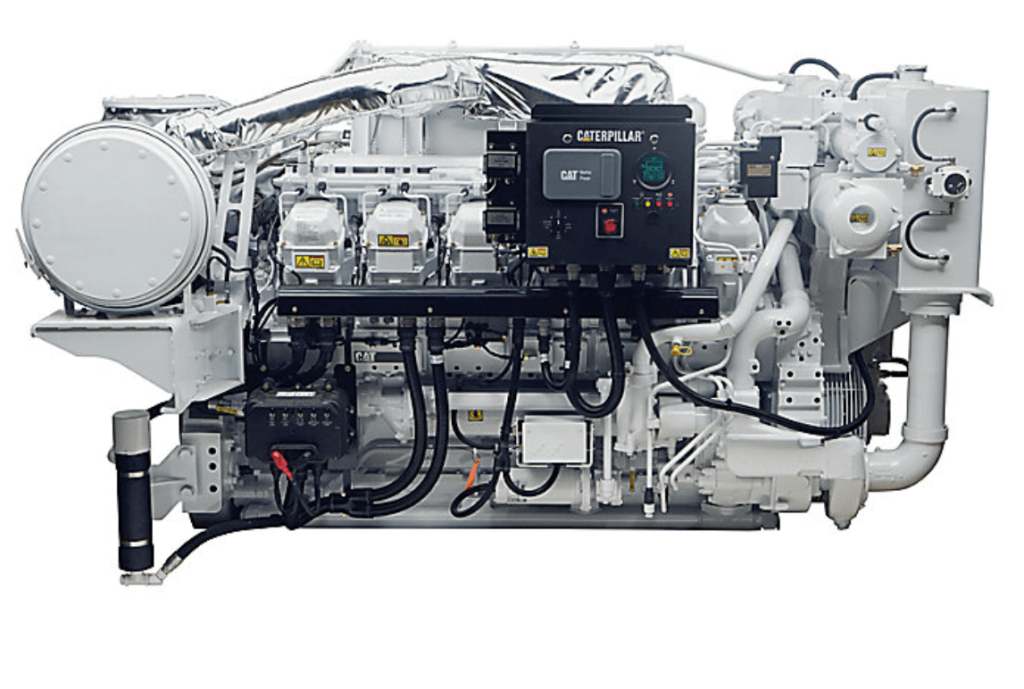

Caterpillar Engine – High Performance Propulsion and Maneuvering Solutions 3512C HD

KEY SPECS

Power Range

1340-2366 bhp (1000-1765 bkW)

Speed Range

1600-1800 rpm

Emissions

EPA Tier 3, IMO II

Overview

The Cat 3512C marine propulsion engine makes your investment work harder. Through a wide range of available power ratings, no required aftertreatment technology, and nominal rated BSFC fuel consumption – it will drive down your total cost of ownership. With a redesigned piston bowl shape to improve combustion, and improved fuel delivery, this engine is IMO II emissions compliant and committed to sustainable environmental development. Single-source support, the Caterpillar warranty, and industry-leading one-year warranty on parts make the 3512C a fully integrated marine power solution

Key Features

Making Your Investment Work Harder: Uses advanced predictive modeling software to select best nozzle configurations and combustion cylinder geometry, Stainless steel exhaust manifold and turbo heat shields, Closed crankcase ventilation system, Dual camshafts, Reduced aftercooler heat load for smaller heat exchanger requirements

Driving down Total Cost of Ownership: A wide range of power ratings available, No aftertreatment technology required, Fuel consumption nominal rated BSFC

Committed to Sustainable Development: Modified piston bowl shape to improve combustion and reduce emissions, Uses K-factor injector to align with predictive model analysis, Better electronic injection control using crank timing vs. cam timing, EPA Marine Tier 3/IMO Tier II Emissions Compliant, Lower IMAT = Lower NOx

Improving Workforce Efficiency: Electronic governing (A4 ECU), Instrument panel shipped loose with Color Marine Power Display (MPD), Cold mode start strategy, Programmable low idle, Optional marine alarm and protection system

Fully Integrated Marine Power Solution: Single-source support, Caterpillar warranty for all factory packaged components, Industry-leading one-year warranty on parts

PRODUCT SPECIFICATIONS FOR 3512C HD

RATINGS

Power Range | 1340-2366 bhp (1000-1765 bkW) |

ENGINE

Speed Range | 1600-1800 rpm |

Emissions | EPA Tier 3, IMO II |

Aspiration | TTA |

Bore | 6.69 in |

Stroke | 8.5 in |

Displacement | 3574 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | Vee 12, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Width | 80.2 in |

Height | 87.5 in |

Dry Weight | 16508 lb |

Length | 104.2 in |

3512C HD STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Powercore air cleaner

CONTROL SYSTEM

- Dual Caterpillar A4 Electronic Engine Control with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

EXHAUST SYSTEM

- 3500C engines:

FUEL SYSTEM

- Fuel transfer pump

- Electronically Controlled Unit Injectors

LUBE SYSTEM

- Crankcase breather groups, Top mounted

- Oil filler and dipstick, LH or RH

- Oil pump, gear type

- 250 or 1000 hour sump oil pan

POWER TAKEOFFS

- Accessory drives: Lower RH, lower LH

- Front housing, two-sided

PROTECTION SYSTEM

- A4 Electronic Monitoring System provides customer programmable engine derating strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel)

- Safety shutoff protection:

GENERAL

- Vibration damper and guard

- Lifting eyes

- NOTE: Engines for heat exchanger cooling do NOT include heat exchange

FLYWHEEL AND FLYWHEEL HOUSING

- Flywheel, SAE No. 00, 183 teeth

- Flywheel housing, SAE No. 00

COOLING SYSTEM

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump

- Aftercooler system: If using glycol, up to maximum 20% glycol concentration is allowed

INSTRUMENTATION

- Electronic service meter, instrument panel (24V), start/stop switch, emergency stop button, maintenance due light, diagnostic light, warning light, maintenance clear switch, start motor magnetic switch, 15 and 3A breakers

- Graphical Unit (Color Marine Power Display) for analog or digital of:

3512C HD OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Air Inlet Adapters

CHARGING SYSTEM

- Battery Chargers

- Charging Alternator

CONTROL SYSTEM

- Throttle Control

COOLING SYSTEM

- Coolant Shunt Tank

- Cooling System Options

EXHAUST SYSTEM

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

FUEL SYSTEM

- Fuel Cooler Heat Exchanger – Sea Water

- Primary Fuel Filter

- Fuel Level Switch

- Rigid Fuel Lines

- Flexible Fuel Lines

INSTRUMENTATION

- Communication Modules

- Color Marine Power Display System

- Pilot House Instrument Panels

- Marine Gear Sensors

LUBE SYSTEM

- Sump Pumps

- Lubricating Oil

POWER TAKE-OFFS

- Stub Shafts

- Crankshaft Pulleys

- Damper Guard

- Flexible Coupling and Guards

MARINE SOCIETY REQUIREMENTS

- Green Passport Documentation

- Spray Shielding

PROTECTION SYSTEM

- Shutoff and Alarm Contactors

SPECIAL APPEARANCE PACKAGES

- Special Appearance Packages with Chrome Covers

- Yacht Class Finish

STARTING SYSTEM

- Air Starting Motor Options

- Battery Sets – 24 Volt – Dry

- Battery Rack

MOUNTING SYSTEM

- Engine Supports

- Vibration Isolation Mountings

PACKING

- Shrink Wrap Protection

- Storage Preservation with Glycol Solution/Vapor Corrosion Inhibitor

- Export Boxing

- Export Packaging