Brand & Engine

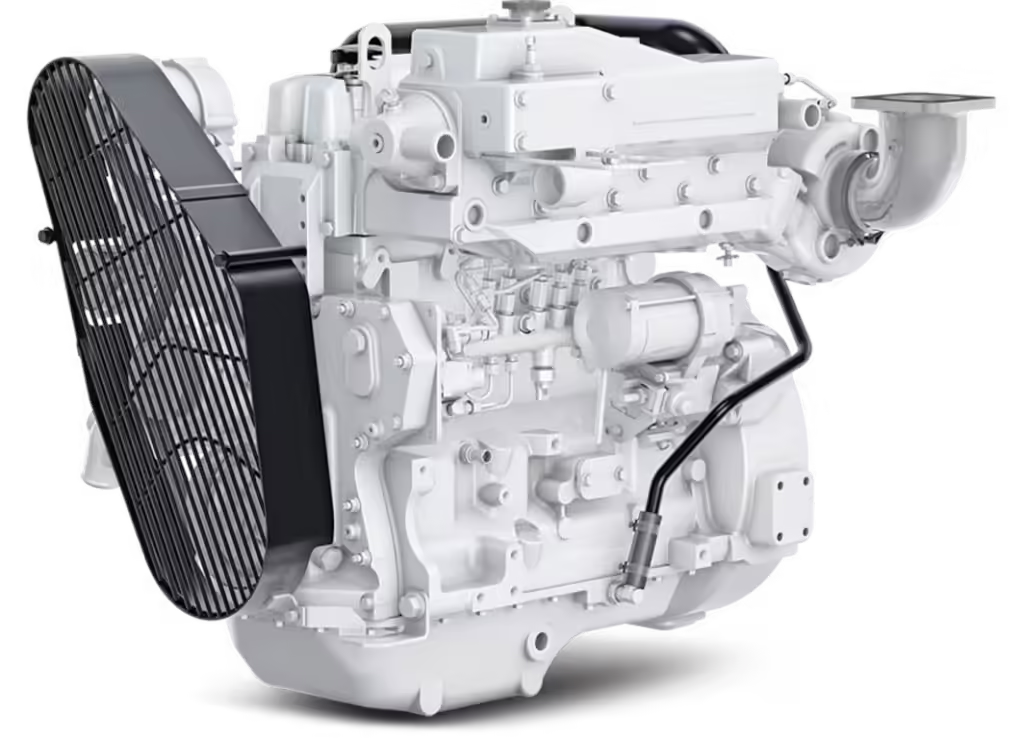

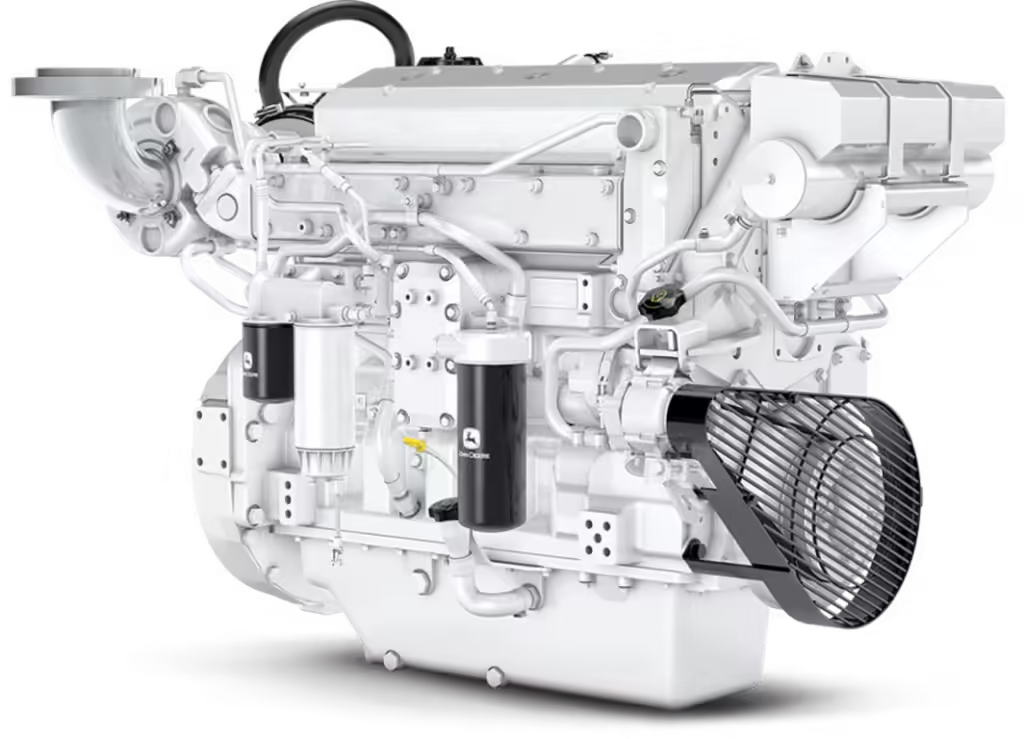

John Deere Engine 22- 4045AFM85 Marine Propulsion Engine

This 4.5L PowerTech™ engine regulates supreme propulsive power at 119-168 kW (160-225 hp) rating. It is ideal for line haul tugs and towboats, fish and shrimp trawlers/draggers, and displacement hull fishing boats. etc.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection. Electronic transfer pump is self-priming for ease of maintenance. Provides high performance, excellent fuel economy, and low emissions.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Integrated heat exchanger

Integrated expansion tank, heat exchanger, and exhaust manifold. High-capacity heat exchanger provides reliable operation in adverse conditions.

Keel-cooled or heat exchanger

Closed cooling system in keel-cooled engine option eliminates the need for a sea strainer, seawater pump, or anodes. Heat exchanger option offers a lighter, more compact, and simpler engine installation.

Internal balancers

Internal balancers reduce engine noise and vibration for crew comfort. NOTE: John Deere 4045 engines only.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

ABS, BV, CCS, CRS, DNV-GL, LR

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 4045AFM85 |

Number of cylinders | 4 |

Displacement– L (cu in) | 4.5 (275) |

Bore and Stroke– mm (in) | 107 x 127 (4.21 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged and air-to-coolant aftercooled |

Engine Dimensions

Length – mm (in) | 1105 (43.5) |

Width Maximum – mm (in) | 864 (34.0) |

Length to rear face of flywheel housing – mm (in) | 890 (35.0) |

Flywheel housing SAE | 3 |

Height – mm (in) | 964 (38.0) |

Height, crankshaft centerline to top – mm (in) | 654 (25.7) |

Height, crankshaft centerline to bottom – mm (in) | 310 (12.2) |

Weight, dry – kg (lb) | 578 (1274) |

Engine Specifications

Performance Rating

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 119 (160) | 2300 | 33.2 (8.8) |

M2 | 134 (180) | 2400 | 36.9 (9.7) |

M3 | 149 (200) | 2500 | 44.2 (11.7) |

M4 | 168 (225) | 2600 | 48.6 (12.8) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65%\ |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 12 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

John Deere Engine 23 - 4045DFM70 - Marine Propulsion Engine

This 4.5L PowerTech™ propulsion engine is compatible for short-range tugs and towboats, long-range ferryboats, large passenger vessels, and offshore displacement hull fishing boats. At 60 kW (80 hp) power rating, it can thrive 3,000 – 5,000 hr of annual usage.

Key Features

Water-cooled exhaust manifold

Cooler and quieter environment for vessel and crew

Replaceable wet-type cylinder liners

- Excellent heat dissipation

- Hardened and precision machined for long life

- Rebuild to original specifications

Internal balancers

Low noise and vibration for crew comfort

Corrosion resistant components

Provides engine protection from the effects of seawater

Either-side service

- Oil fill and dipstick combinations

- Remote oil filter for easier service access

- Application and service flexibility to provide installation convenience plus fast and easy maintenance

Heat exchanger or keel-cooled

- High-capacity heat exchanger designed for reliable operation in adverse conditions

- Integrated expansion tank, heat exchanger and exhaust manifold reduce chances of leaks

- Keel-cooled options provide application flexibility

High torque and low rated RPM

- Enables the engine to turn larger propellers at lower speed for best efficiency

- Excellent vessel control and maneuvering

- Lower rated rpm limits vibration and noise for better crew comfort

Fuel System

Proven and reliable Mechanical Governor

Classification Societies

BV, CCS, CRS, DNV-GL, LR, PRS

Emissions Certifications

IMO Compliant

Technical Specifications

Model | 4045DFM70 |

Number of cylinders | 4 |

Displacement– L (cu in) | 4.5 (275) |

Bore and Stroke– mm (in) | 107 x 127 (4.21 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Naturally aspirated |

Engine Dimensions

Length – mm (in) | 885 (34.8) |

Width Maximum – mm (in) | 713 (28.1) |

Height – mm (in) | 912 (35.9) |

Weight, dry – kg (lb) | 437 (963) |

Performance Rating

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M2 | 60 (82) | 2500 | 17.5 (4.6) |

M Rating

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

John Deere Engine 24- 4045SFM85 Marine Propulsion Engine

This 4.5L PowerTech™ propulsion engine is ideal for inshore crew boats, charter fishing boats, pilot boats, dive boats, and planning hull commercial fishing boats, recreational boats, tactical military vessels, and rescue boats. It has 205-235 kW (275-315 hp) power rating with 35 to 40 percent load factor and 1000-3000 hours of annual usage.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

Turbocharged with air-to-seawater aftercooling

Cooler turbocharger operation enables higher ratings and efficiencies or applications that require high power or speed.

Multiple service options

Standard front fuel service, optional left-hand or right-hand oil filter options for twinengine applications.

Water-cooled exhaust manifold

- Integrated components eliminate external hoses and fitting

- Wet exhaust manifold creates a cooler and quieter environment for passengers and crew

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection. Electronic transfer pump is self-priming for ease of maintenance. Provides high performance, excellent fuel economy, and low emissions.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

Integrated heat exchanger

Integrated expansion tank, heat exchanger, and exhaust manifold reduce the chance of leaks. High-capacity heat exchanger provides reliable operation in adverse conditions.

Internal balancers

Internal balancers reduce engine noise and vibration for crew comfort.

NOTE: John Deere 4045 engines only.

Classification Societies

ABS, BV, DNV-GL, LR

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

- Recreational Craft Directive II (2013/53/EU)

Technical Specifications

Model | 4045SFM85 |

Number of cylinders | 4 |

Displacement– L (cu in) | 4.5 (275) |

Bore and Stroke– mm (in) | 107 x 127 (4.21 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged and air-to-seawater aftercooled |

Engine Dimensions

Length – mm (in) | 1145 (45.1) |

Length to rear face of flywheel housing – mm (in) | 900 (35.4)\ |

Flywheel housing SAE | 2, 3 |

Height – mm (in) | 922 (36.2) |

Height, crankshaft centerline to top – mm (in) | 611 (24.0) |

Height, crankshaft centerline to bottom – mm (in) | 311 (12.2) |

Weight, dry – kg (lb) | 558 (1230) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M4 | 205 (275) | 2600 | 54 (14) |

M5 | 235 (315) | 2800 | 62 (16) |

M Rating

M4 – Typical load factor | >40% |

M4 – Typical annual usage (hr) | 1,000-3,000 hr |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M5 – Typical load factor | <=35% |

M5 – Typical annual usage (hr) | 300-1,000 hr |

M5 – Typical full-power operation (hr) | 0.5 of each 8 hr |

John Deere Engine 25 - 4045TFM50 - Marine Propulsion Engine

This 4.5L PowerTech™ propulsion engine with standard 112 kW (150 hp) power rating supports a wide range of applications including:

- line haul tugs and towboats

- fish and shrimp trawlers/draggers

- displacement hull fishing boats

- short-range tugs and towboats

- long-range ferryboats

- large passenger vessels

- offshore displacement hull fishing boats

- coastal fishing boats

- offshore crew boats

- research boats

- short-range ferryboats

- dinner cruise boats

- inshore crew boats

- charter fishing boats

- pilot boats

- dive boats

- planning hull commercial fishing boats

Key Features

Water-cooled exhaust manifold

Cooler and quieter environment for vessel and crew

Replaceable wet-type cylinder liners

- Excellent heat dissipation

- Hardened and precision machined for long life

- Rebuild to original specifications

Internal balancers

Low noise and vibration for crew comfort

Corrosion resistant components

Provides engine protection from the effects of seawater

Either-side service

- Oil fill and dipstick combinations

- Remote oil filter for easier service access

- Application and service flexibility to provide installation convenience plus fast and easy maintenance

Fuel system

Proven and reliable Mechanical Governor

Heat exchanger or keel-cooled

- High-capacity heat exchanger designed for reliable operation in adverse conditions

- Integrated expansion tank, heat exchanger and exhaust manifold

- Keel-cooled or heat exchanger options provide application flexibility

High torque and low rated RPM

- Enables the engine to turn larger propellers at lower speed for best efficiency

- Excellent vessel control and maneuvering

- Lower rated rpm limits vibration and noise for better crew comfort

Classification Societies

CRS, DNV-GL, RINA

Emissions Certifications

Non-Emissions Certified

Technical Specifications

Model | 4045TFM50 |

Number of cylinders | 4 |

Displacement– L (cu in) | 4.5 (275) |

Bore and Stroke– mm (in) | 106 x 127 (4.17 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged |

Engine Dimensions

Length – mm (in) | 885 (34.8) |

Width Maximum – mm (in) | 712 (28.0) |

Height – mm (in) | 912 (35.9) |

Weight, dry – kg (lb) | 462 (1019) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 78 (105) | 2300 | N/A |

M2 | 90 (121) | 2400 | N/A |

M3 | 101 (135) | 2500 | 26.3 (6.9) |

M4 | 112 (150) | 2600 | 29.7 (7.8) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | < 65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 12 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

John Deere Engine 26 - 4045TFM85 - Marine Propulsion Engine

The 4045TFM85 4.5L PowerTech™ propulsion engines have a medium 75-93 kW (100-125 hp) power rating ideal for up to 3000- 5000 hours of annual usage.

This engine pairs well with line haul tugs and towboats, fish and shrimp trawlers/draggers, and displacement hull fishing boats, short-range tugs and towboats, long-range ferryboats, large passenger vessels, and offshore displacement hull fishing boats.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection. Electronic transfer pump is self-priming for ease of maintenance. Provides high performance, excellent fuel economy, and low emissions.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Integrated heat exchanger

Integrated expansion tank, heat exchanger, and exhaust manifold reduce the chance of leaks. High-capacity heat exchanger provides reliable operation in adverse conditions.

Keel-cooled or heat exchanger

Closed cooling system in keel-cooled engine option eliminates the need for a sea strainer, seawater pump, or anodes. Heat exchanger option offers a lighter, more compact, and simpler engine installation.

Internal balancers

Internal balancers reduce engine noise and vibration for crew comfort. NOTE: John Deere 4045 engines only.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

CCS, DNV-GL

Emissions Certifications

EPA Commercial Marine Tier 3

Technical Specifications

Model | 4045TFM85 |

Number of cylinders | 4 |

Displacement– L (cu in) | 4.5 (275) |

Bore and Stroke– mm (in) | 106 x 127 (4.17 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged |

Engine Dimensions

Length – mm (in) | 1020 (40.2) |

Width Maximum – mm (in) | 808 (31.8) |

Length to rear face of flywheel housing – mm (in) | 877 (34.5) |

Flywheel housing SAE | 3 |

Height – mm (in) | 912 (35.9) |

Height, crankshaft centerline to top – mm (in) | 625 (24.6) |

Height, crankshaft centerline to bottom – mm (in) | 287 (11.3) |

Weight, dry – kg (lb) | 507 (1118) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 50 (67) | 2400 | 21.5 (5.7) |

M2 | 93 (125) | 2500 | 29.1 (7.7) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

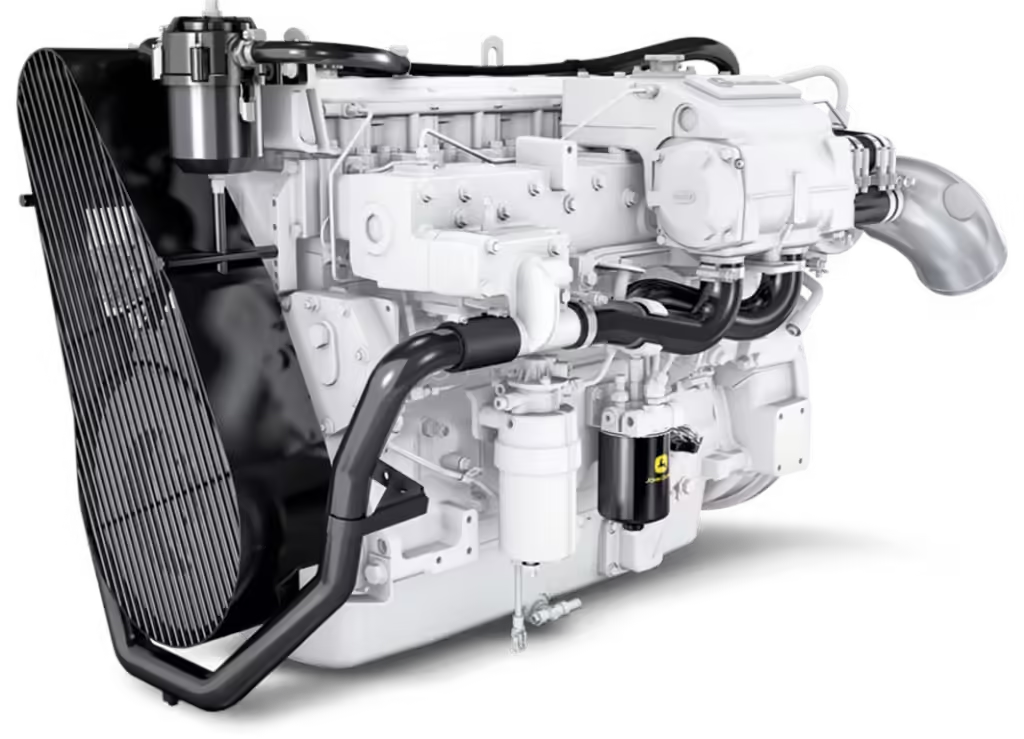

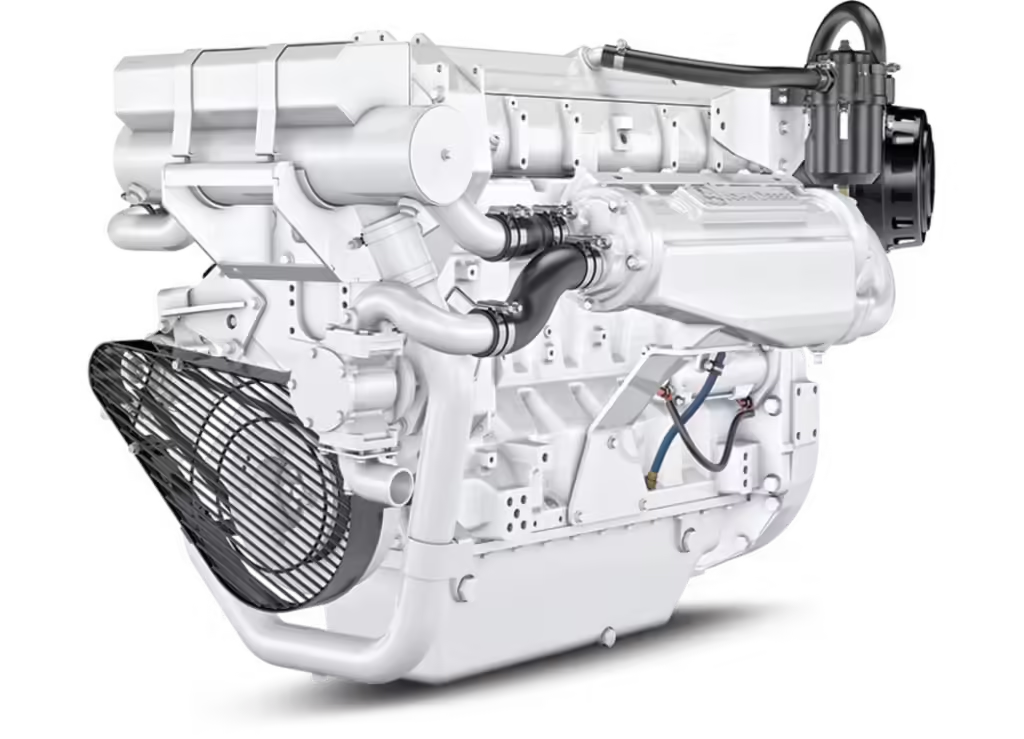

John Deere Engine 27 - 6068AFM85 - Marine Propulsion Engine

This 6.8L PowerTech™ propulsion engine has a robust 172-246 kW (230-330 hp) power rating. It is ideal for vessels in the JD M1 to M4 ratings, including recreational boats, launches, work boats, trawler yachts, and patrol craft.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection. Electronic transfer pump is self-priming for ease of maintenance. Provides high performance, excellent fuel economy, and low emissions.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Keel-cooled or heat exchanger

Closed cooling system in keel-cooled engine option eliminates the need for a sea strainer, seawater pump, or anodes. Heat exchanger option offers a lighter, more compact, and simpler engine installation.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

ABS, BV, CCS, DNV, LR

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Compliant

- NRMM (97/68/EC) as amended

Technical Specifications

Model | 6068AFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 6 (6) |

Bore and Stroke– mm (in) | 107 x 127 (4.21 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged and air-to-coolant aftercooled |

Engine Dimensions

Length – mm (in) | 1489 (58.6) |

Length to rear face of flywheel housing – mm (in) | 1172 (46.1) |

Width Maximum – mm (in) | 862 (33.9) |

Flywheel housing SAE | 2 |

Height – mm (in) | 935 (36.8) |

Height, crankshaft centerline to top – mm (in) | 644 (25.4) |

Height, crankshaft centerline to bottom – mm (in) | 291 (11.5) |

Weight, dry – kg (lb) | 787 (1735) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 172 (230) | 2300 | N/A |

M2 | 198 (266) | 2400 | 57.9 (15.3) |

M3 | 224 (300) | 2500 | 76.0 (20.1) |

M4 | 246 (330) | 2600 | 71.2 (18.8) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 12 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

John Deere Engine 28- 6068SFM85 - Marine Propulsion Engine

This 6.8L PowerTech™ engine has an impressive 186-298 kW (249-400 hp) power rating. It is suited for operating recreational boats, launches, work boats, trawler yachts, and patrol craft.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection. Electronic transfer pump is self-priming for ease of maintenance. Provides high performance, excellent fuel economy, and low emissions.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Turbocharged with air-to-seawater aftercooling

Cooler turbocharger operation enables higher ratings and efficiencies for applications that require high power or speed.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Heat exchanger

High-capacity heat exchanger provides reliable operation in adverse conditions.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

ABS, BV, CCS, CRS, DNV-GL, LR

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 6068SFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 6.8 (415) |

Bore and Stroke– mm (in) | 106 x 127 (4.17 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Air-to-sea water |

Engine Dimensions

Length – mm (in) | 1489 (58.6) |

Width Maximum – mm (in) | 872 (34.3) |

Height – mm (in) | 931 (36.7) |

Height, crankshaft centerline to top – mm (in) | 640 (25.2) |

Height, crankshaft centerline to bottom – mm (in) | 291 (11.5) |

Weight, dry – kg (lb) | 763 (1682) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 186 (249) | 2400 | 51.1 (13.5) |

M2 | 209 (280) | 2500 | 56.7 (15.0) |

M3 | 239 (321) | 2600 | 63.3 (16.7) |

M4 | 265 (355) | 2700 | 69.3 (18.3) |

M5 | 298 (400) | 2800 | 81.3 (21.5) |

M rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 12 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

M5 – Typical annual usage (hr) | 000 hr |

M5 – Typical full-power operation (hr) | 0.5 of each 8 hr |

M5 – Typical load factor | <=35% |

John Deere Engine 29 - 6068TFM50 - Marine Propulsion Engine

This 6.8L PowerTech™ engine regulates propulsive power at 115-168 kW (154-225 hp). These engines can be configured for optimum performance in recreational boats, launches, work boats, trawler yachts, and patrol craft.

Key Features

Water-cooled turbocharger and exhaust manifold

Cooler and quieter environment for vessel and crew

Replaceable wet-type cylinder liners

- Excellent heat dissipation

- Hardened and precision machined for long life

- Rebuild to original specifications

Corrosion resistant components

Provides engine protection from the effects of seawater

Either-side service

- Oil fill and dipstick combinations

- Remote oil filter for easier service access

- Application and service flexibility to provide installation convenience plus fast and easy maintenance

Heat exchanger or keel-cooled

- High-capacity heat exchanger designed for reliable operation in adverse conditions

- Integrated expansion tank, heat exchanger and exhaust manifold

- Keel cooler or heat exchanger options provide application flexibility

High torque and low rated RPM

- Enables the engine to turn larger propellers at lower speed for best efficiency

- Excellent vessel control and maneuvering

- Lower rated rpm limits vibration and noise for better crew comfort

Fuel system

Proven and reliable Mechanical Governor

Classification Societies

CRS, DNV-GL, RINA

Emissions Certifications

IMO Compliant

Technical Specifications

Model | 6068TFM50 |

Number of cylinders | 6 |

Displacement– L (cu in) | 6.8 (415) |

Bore and Stroke– mm (in) | 106 x 127 (4.17 x 5.00) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged |

Engine Dimensions

Length – mm (in) | 1141 (44.9) |

Width Maximum – mm (in) | 712 (28.0) |

Height – mm (in) | 881 (34.7) |

Weight, dry – kg (lb) | 730 (1609) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 115 (154) | 2300 | N/A |

M2 | 130.5 (175) | 2400 | 36.3 (9.6) |

M3 | 149 (200) | 2500 | N/A |

M4 | 168 (225) | 2600 | 46.8 (12.4) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | <65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 12 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

John Deere Engine 30- 6090AFM85 - Marine Propulsion Engine

The 9.0L PowerTech™ propulsion engine has 213-317 kW (285-425 hp) power rating. It empowers vessels in the patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats categories.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and controls fuel injection timing and provides precise control for the start, duration, and end of injection.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Keel-cooled or heat exchanger

Closed cooling system in keel-cooled engine option eliminates the need for a sea strainer, seawater pump, or anodes. Heat exchanger option offers a lighter, more compact, and simpler engine installation.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

ABS, BV, CCS, DNV-GL, LR

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 6090AFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 9.0 (549) |

Bore and Stroke– mm (in) | 118 x 136 (4.65 x 5.35) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged and air-to-coolant aftercooled |

Engine Dimensions

Length – mm (in) | 1712 (67.4) |

Width Maximum – mm (in) | 1027 (40.4) |

Length to rear face of flywheel housing – mm (in) | 1415 (55.7) |

Flywheel housing SAE | 2 |

Height – mm (in) | 984 (38.7) |

Height, crankshaft centerline to top – mm (in) | 665 (26.2) |

Height, crankshaft centerline to bottom – mm (in) | 319 (12.6) |

Weight, dry – kg (lb) | 1055 (2326) |

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 64.6 (17.1) | 2100 | 213 (286) |

M2 | 243 (326) | 2200 | 71.4 (18.9) |

M3 | 280 (375) | 2300 | 80.9 (21.4) |

M4 | 317 (425) | 2400 | 91.2 (24.1) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 16 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

John Deere Engine 31 - 6090SFM85 - Marine Propulsion Engine

This 9.0L PowerTech™ engine boast composition for hybrid vessels. The 242-410 kW (325-550 hp) power rating makes it an ideal fit for patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats.

It is best suited for hybrid vessels that require variable-speed generator drive engine for regulating electrical power for electric propulsion, energy storage, hotel load, and auxiliary electric loads.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

High-pressure common-rail (HPCR)

The HPCR fuel system provides variable common-rail pressure, multiple injections, and controls fuel injection timing and provides precise control for the start, duration, and end of injection.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Turbocharged with air-to-seawater aftercooling

Cooler turbocharger operation enables higher ratings and efficiencies for applications that require high power or speed.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Heat exchanger

High-capacity heat exchanger provides reliable operation in adverse conditions.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

ABS, BV, CCS, DNV-GL, LR

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 6090SFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 9.0 (549) |

Bore and Stroke– mm (in) | 118.4 x 136 (4.66 x 5.35) |

Engine Type | In-line, 4- Cycle |

Aspiration | Air-to-sea water |

Engine Dimensions

Length – mm (in) | 1712 (67.4) |

Width Maximum – mm (in) | 974 (38.3) |

Length to rear face of flywheel housing – mm (in) | 1415 (55.7) |

Flywheel housing SAE | 2 |

Height – mm (in) | 983 (38.7) |

Height, crankshaft centerline to top – mm (in) | 664 (26.1) |

Height, crankshaft centerline to bottom – mm (in) | 319 (12.6) |

Weight, dry – kg (lb) | 1056 (2328) |

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 242 (325) | 2100 | 65.4 (17.3) |

M2 | 280 (375) | 2200 | 77.6 (20.5) |

M3 | 317 (425) | 2300 | 87.4 (23.1) |

M4 | 373 (500) | 2400 | 107.1 (28.3) |

M5 | 410 (550) | 2500 | 115.6 (30.5) |

H | 242 (325) | 2000 | 63.2 (16.7) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 16 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

M5 – Typical annual usage (hr) | 000 hr |

M5 – Typical full-power operation (hr) | 0.5 of each 8 hr |

M5 – Typical load factor | <=35% |

H – Typical annual usage (hr) | Unrestricted |

H – Typical full-power operation (hr) | Uninterrupted |

H – Typical load factor | ≤ 70% |

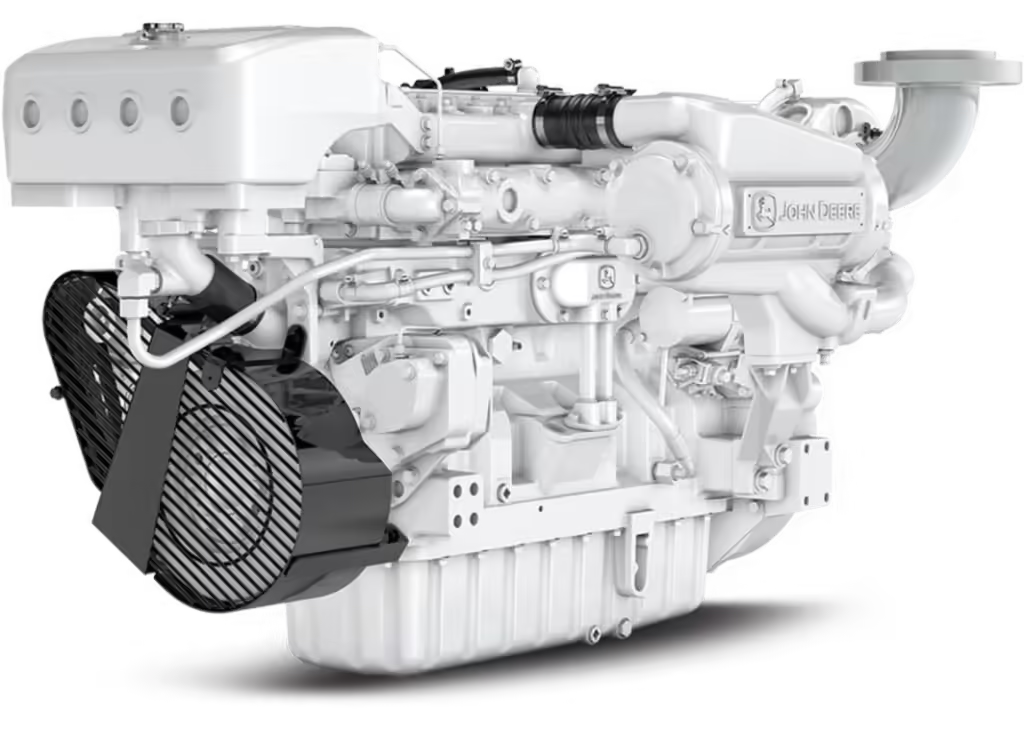

John Deere Engine 32 - 6135AFM85 - Marine Propulsion Engine

6135AFM85 13.5L PowerTech™ engines feature 272-429 kW (365-575 hp) power rating. The M1 rated engines induce dynamic propulsion to operate your watercraft for up to 24 hours per day at uninterrupted full power. With load factor greater than 65%, the engine can power patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats.

Key Features

High torque and low rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

Electronic unit injectors (EUI)

The EUI fuel system provides higher injection pressures. It also controls fuel injection timing and provides precise control for start, duration, and end of injection.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Keel-cooled or heat exchanger

Closed cooling system in keel-cooled engine option eliminates the need for a sea strainer, seawater pump, or anodes. Heat exchanger option offers a lighter, more compact, and simpler engine installation.

Multiple service options

Either-side oil fill/dipstick combinations and remote oil and fuel filter options are available for easier service access.

Classification Societies

ABS, BV, DNV-GL, LR, PRS

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 6135AFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 13.5 (824) |

Bore and Stroke– mm (in) | 132 x 165 (5.20 x 6.50) |

Engine Type | In-line, 4- Cycle |

Aspiration | Turbocharged and air-to-coolant aftercooled |

Engine Dimensions

Length – mm (in) | 1801 (70.9) |

Width Maximum – mm (in) | 1062 (41.8) |

Height – mm (in) | 1266 (49.8) |

Height, crankshaft centerline to top – mm (in) | 902 (35.5) |

Height, crankshaft centerline to bottom – mm (in) | 364 (14.3) |

Weight, dry – kg (lb) | 1410 (3109) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 272 (365) | 1800 | 76.7 (20.3) |

M2 | 317 (425) | 1900 | 86.2 (22.8) |

M3 | 373 (500) | 2000 | 102.2 (27.0) |

M4 | 429 (575) | 2100 | 118.8 (31.4) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 12 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

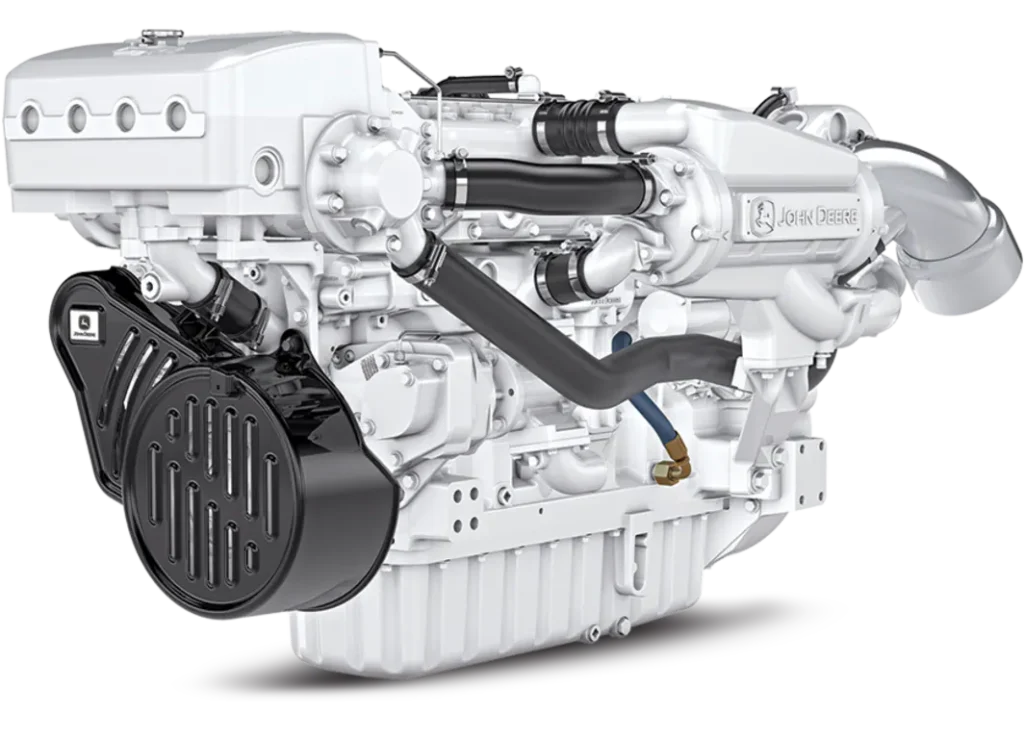

John Deere Engine 33 - 6135SFM85 - Marine Propulsion Engine

The powerful 6135SFM85 13.5L PowerTech™ engines have massive 317-559 kW (425-750 hp) power rating. From light recreational boats to heavy-duty vessels operating up to 5000 hours per year, the engine is compatible for patrol craft, launches, work boats, fishing boats, trawler yachts, and sportfishing boats.

Key Features

High Torque and Low Rated RPM

High torque provides excellent vessel control and maneuverability. Lower rated propulsion RPM reduces vibration and noise for improved crew comfort.

4-valve cylinder head

Excellent airflow through 4-valve cylinder head delivers greater low-speed torque and better transient response time.

Electronic unit injectors (EUI)

The EUI fuel system provides higher injection pressures. It also controls fuel injection timing and provides precise control for start, duration, and end of injection.

Water-cooled exhaust manifold

Integrated components eliminate external hoses and fittings. Wet exhaust manifold creates a cooler and quieter environment for passengers and crew.

Turbocharged with air-to-seawater aftercooling

Cooler turbocharger operation enables higher ratings and efficiencies for applications that require high power or speed.

Replaceable cylinder liners

Replaceable wet-type cylinder liners are precision-machined and hardened for long life. Allows engine to be rebuilt to original specifications.

Electronic engine control unit (ECU)

Advanced fault code diagnostics and customizable engine protections ensure reliability and uptime. Provides highly customizable features and trim to integrate your vessel.

Heat exchanger

High-capacity heat exchanger provides reliable operation in adverse conditions.

Classification Societies

ABS, BV, DNV-GL, LR, PRS

Emissions Certifications

- EPA Commercial Marine Tier 3

- IMO MARPOL Annex VI Tier II Compliant

Technical Specifications

Model | 6135SFM85 |

Number of cylinders | 6 |

Displacement– L (cu in) | 13.5 (824) |

Bore and Stroke– mm (in) | 132 x 165 (5.20 x 6.50) |

Engine Type | In-line, 4- Cycle |

Aspiration | Air-to-sea water |

Engine Dimensions

Length – mm (in) | 1819 (71.6) |

Width Maximum – mm (in) | 1036 (40.8) |

Height – mm (in) | 1266 (49.8) |

Height, crankshaft centerline to top – mm (in) | 902 (35.5) |

Height, crankshaft centerline to bottom – mm (in) | 364 (14.3) |

Weight, dry – kg (lb) | 1426 (3144) |

Engine Specifications

Performance Rating | Power KW (bhp) | Rated Speed (rpm) | Rated fuel consumption L/hr(gal/hr) |

M1 | 317 (425) | 1800 | 79.5 (21.0) |

M2 | 373 (500) | 1900 | 94.4 (24.9) |

M3 | 429 (575) | 2000 | 110.9 (29.3) |

M4 | 485 (650) | 2100 | 124.7 (32.9) |

M5 | 559 (750) | 2200 | 145.9 (38.5) |

M Rating

M1 – Typical annual usage (hr) | Unrestricted |

M1 – Typical full-power operation (hr) | Uninterrupted |

M1 – Typical load factor | >65% |

M2 – Typical annual usage (hr) | 000-5 |

M2 – Typical full-power operation (hr) | 16 of each 24 hr |

M2 – Typical load factor | <=65% |

M3 – Typical annual usage (hr) | 000-4 |

M3 – Typical full-power operation (hr) | 4 of each 16 hr |

M3 – Typical load factor | <=50% |

M4 – Typical annual usage (hr) | 000-3 |

M4 – Typical full-power operation (hr) | 1 of each 12 hr |

M4 – Typical load factor | <=40% |

M5 – Typical annual usage (hr) | 000 hr |

M5 – Typical full-power operation (hr) | 0.5 of each 8 hr |

M5 – Typical load factor | <=35% |