Brand & Engine

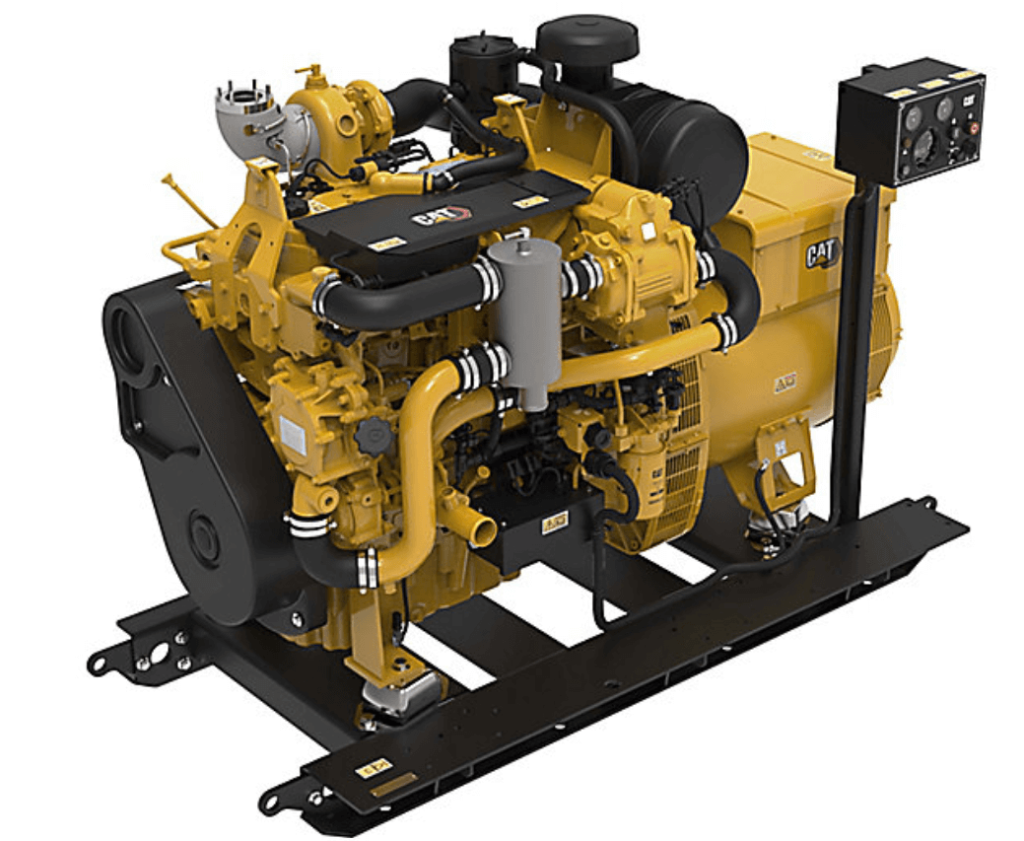

Caterpillar Engine 35 – Marine Generator Sets C4.4 (Electronic)

KEY SPECS

Power Range

65/75/99/118 ekW @ 1800 rpm (60 Hz), 65/80/99 ekW @ 1500 rpm (50 Hz)

Emissions

U.S. EPA Tier 3 certified, EU Stage V certified

Configuration

In-line 4, 4-stroke-cycle diesel

Overview

C4.4 (Electronic Control System)

Key Features and Benefits

- Simplicity = Reliability

• Configure the engine how you want it

• Compact engine profile with high power density

• Ease of repower with multiple cooling system options: Single circuit keel cooling /Separate circuit keel cooling / Heat exchanger

• Clean, smooth, and quiet operations

• Advanced fuel system provides excellent fuel consumption and low smoke

• Proven core engine design with millions of operating hours

• Fewer maintenance touchpoints and longer service intervals

• Global dealer network for unparalleled support

PRODUCT SPECIFICATIONS FOR C4.4 (ELECTRONIC)

POWER RATING

Power Range | 65/75/99/118 ekW @ 1800 rpm (60 Hz), 65/80/99 ekW @ 1500 rpm (50 Hz) |

ENGINE SPECIFICATIONS

Emissions | U.S. EPA Tier 3 certified, EU Stage V certified |

Configuration | In-line 4, 4-stroke-cycle diesel |

Rated Engine Speed | 1500/1800 rpm |

Bore | 4.13 in |

Stroke | 5 in |

Displacement | 268 in³ |

Aspiration | Turbocharged-aftercooled and turbo only aspiration (Turbocharged aspiration only for 65ekW (71bkW)) |

Governor | Electronic (A5 ECM) |

Refill Capacity | Lube Oil System w/Oil filter change: 11 L 2.8 gal) |

Oil Change Interval | 500 hrs |

Cooling | Heat exchanger, combined circuit keel cooling, or separate circuit keel cooling |

Flywheel Housing | SAE No. 03 with SAE 11.5 flywheel (126 teeth) |

DIMENSIONS & WEIGHTS

Maximum Length | 80.2 in |

Maximum Height | 78.7 in |

Maximum Width | 38.3 in |

Maximum Engine Dry Weight | 3389 lb |

C4.4 (ELECTRONIC) STANDARD EQUIPMENT

COOLING SYSTEM

- Gear-driven jacket-water and auxiliary water pumps

- Engine mounted air cleaner and expansion tank

- Integral plate-type oil cooler

EXHAUST SYSTEM

- Watercooled exhaust manifold and turbocharger

FUEL SYSTEM

- Common Rail fuel system

LUBE SYSTEM

- Open crankcase ventilation system

MOUNTING SYSTEM

- Engine mounted fuel and oil filter

- Engine mounted customer interface and control relays

STARTING SYSTEM

- 12V or 24V starter motor

GENERAL

- 3-phase AREP generators with 300% short circuit capability

- Digital Automatic Voltage Regulator

- Class H generator insulation

C4.4 (ELECTRONIC) OPTIONAL EQUIPMENT

GENERAL

- MGGP 200 Gauge Panel and interface harness

- Engine shutdown sensors and shutdown controller

- Double wall high pressure fuel lines

- EMCP engine control panel

- MGCP II engine control panel

- AC Voltage Monitoring

- Glow plugs

- Factory installed generator space heater kit

- MCS Certifications

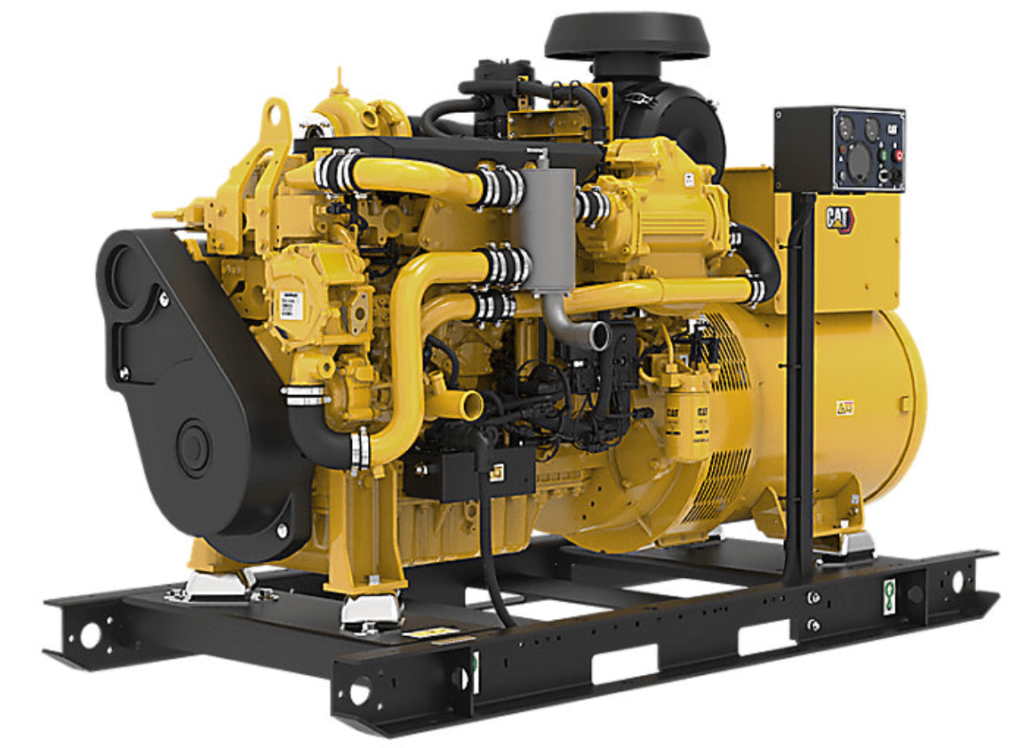

Caterpillar Engine – Marine Generator Sets C1.5

KEY SPECS

Maximum Rating

12 ekW (12 kVA)

Speed

1500 / 1800 rpm

Emissions

U.S. EPA Tier 3

Overview

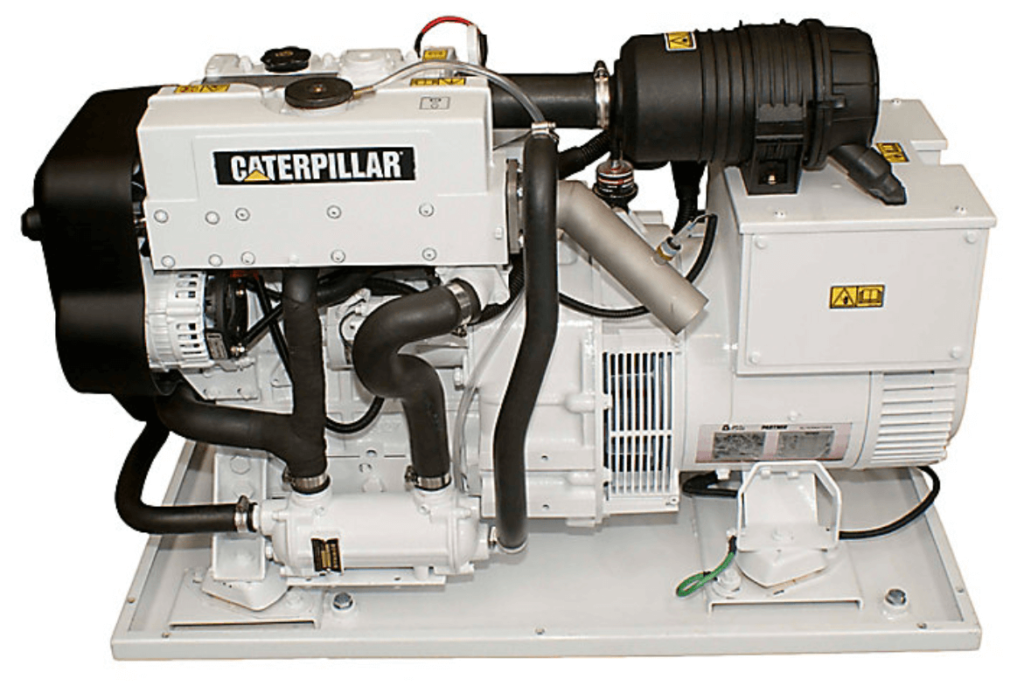

Cat® C1.5 Diesel Marine Generator Set

Key Features & Benefits

- This compact unit provides required power on demand, operating very efficiently with optimum performance.

- The 3 cylinder naturally aspirated engine operates with little vibration and low sound levels.

- Available as an open set or with a sound enclosure, this package is ideal for power requirements in any application.

- Low operating and maintenance costs with excellent fuel economy.

- The single side servicing with extended service intervals makes maintenance easy.

PRODUCT SPECIFICATIONS FOR C1.5

GENERATOR SET SPECIFICATIONS

Maximum Rating | 12 ekW (12 kVA) |

Speed | 1500 / 1800 rpm |

Minimum Rating | 10 ekW (10 kVA) |

Frequency | 50 Hz or 60 Hz |

ENGINE SPECIFICATIONS

Emissions | U.S. EPA Tier 3 |

Configuration | Inline 3, 4-Stroke Cycle diesel |

Displacement | 91 in³ |

Aspiration | Naturally Aspirated |

Governor Type | Electrical Isochronous |

Bore | 3.31 in |

Stroke | 3.5 in |

Refill Capacity | Lube Oil System w/oil filter change: 6 L (1.6 gal) |

Oil Change Interval | 500 hrs |

Rotation from Flywheel End | Counterclockwise |

Cooling | Hex or Single Circuit Keel |

GENERATOR SET DIMENSIONS

Length | 40.8 in / 1,038 mm (open) 43.1 in / 711 mm (enclosed) |

Width | 21.1 in / 535 mm (open) 24 in / 608 mm (enclosed) |

Height | 27.1 in / 535 mm (open) 27.9 in / 711 mm (enclosed) |

Engine Dry Weight | 703 lb / 319 kg |

C1.5 STANDARD EQUIPMENT

STANDARD EQUIPMENT

- Single element air cleaner

- Water-cooled exhaust manifold

- Single or Three phase brushless generator

- 12 or 24 volt electric starting motor

- 12 volt 55 amp alternator

- Single sided service points

- Anti-vibration mounts.

- Electronic automatic safety shutdowns

C1.5 OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- Sound attenuated enclosure (Factory Fit or Upgrade Kit)

- Keel cooling kit

- Basic, Deluxe and remote panel options

- AC circuit breakers

- Flexible fuel lines

- Primary fuel filter/water separator

- Siphon break

- Exhaust system components

- Insulated electrical system

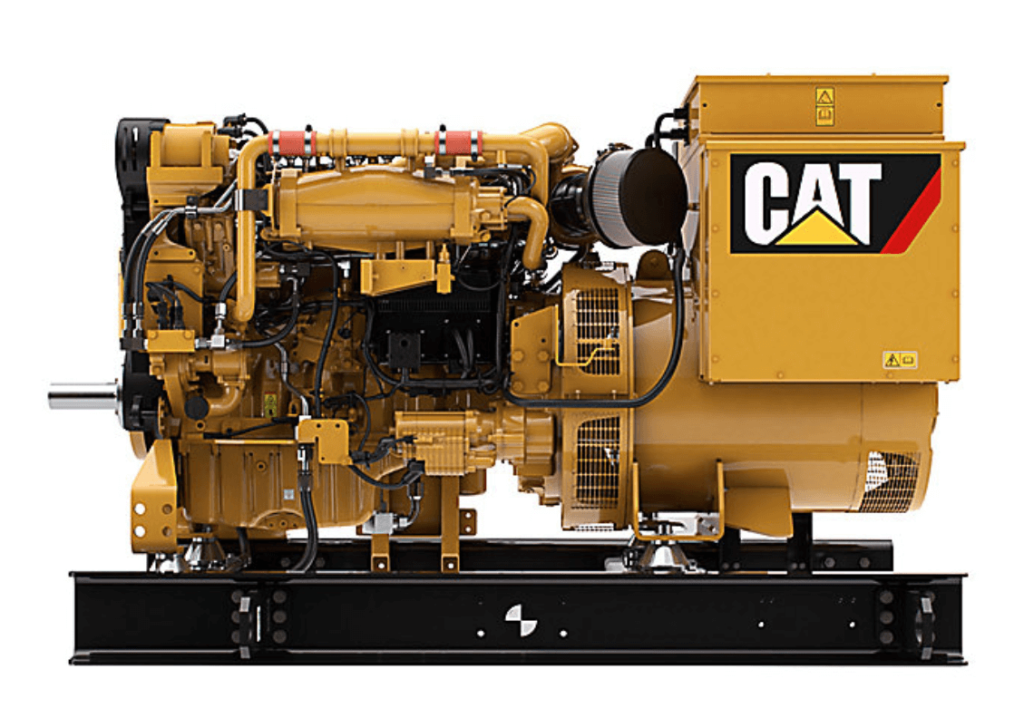

Caterpillar Engine 37 – Marine Generator Sets C2.2

KEY SPECS

Maximum Rating

25 ekW (25 kVA)

Rated Engine Speed

1500 / 1800 rpm

Emissions

U.S. EPA Tier 3

Overview

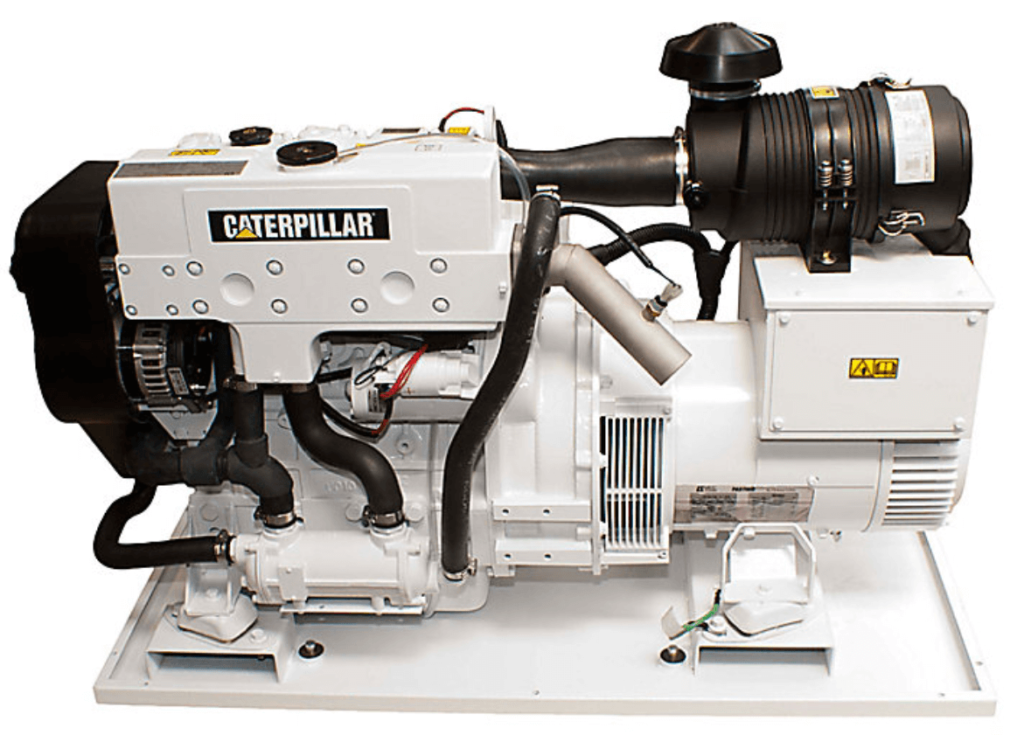

Cat® C2.2 Diesel Marine Generator Set

Key Features & Benefits

- This compact unit provides required power on demand, operating very efficiently with optimum performance.

- The 4 cylinder engine operates with little vibration and low sound levels.

- Available as an open set or with a sound enclosure, this package is ideal for power requirements in any application.

- Low operating and maintenance costs with excellent fuel economy.

- Single side servicing with extended service intervals makes maintenance easy.

PRODUCT SPECIFICATIONS FOR C2.2

GENERATOR SET SPECIFICATIONS

Maximum Rating | 25 ekW (25 kVA) |

Minimum Rating | 15 ekW (15 kVA) |

ENGINE SPECIFICATIONS

Rated Engine Speed | 1500 / 1800 rpm |

Emissions | U.S. EPA Tier 3 |

Configuration | Inline 4, 4-Stroke Cycle diesel |

Displacement | 135 in³ |

Aspiration | Naturally Aspirated / Turbocharged |

Governor Type | Electrical Ischronous |

Bore | 3.31 in |

Stroke | 3.5 in |

Refill Capacity | Lube Oil System w/oil filter change: 10.6 L (2.8 gal) |

Oil Change Interval | 500 hrs |

Rotation from Flywheel End | Counterclockwise |

Cooling | Hex or Single Circuit Keel |

GENERATOR SET DIMENSIONS

Length | 47.9 in / 1,219 mm (open) 50.7 in / 1,290 mm (enclosed) |

Width | 22.3 in / 567 mm (open) 24.7 in / 628 mm (enclosed) |

Height | 32.8 in / 835 mm (open) 31 in / 775 mm (enclosed) |

Engine Dry Weight | 857-1,027 lb / 386-466 kg |

C2.2 STANDARD EQUIPMENT

STANDARD EQUIPMENT

- Single element air cleaner

- Water-cooled exhaust manifold

- Single or Three phase brushless generator

- 12 or 24 volt electric starting motor

- 12 volt 55 amp alternator

- Single sided service points

- Anti-vibration mounts.

- Electronic automatic safety shutdowns

C2.2 OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- Sound attenuated enclosure (Factory Fit or Upgrade Kit)

- Keel cooling kit

- Basic, Deluxe and remote panel options

- AC circuit breakers

- Flexible fuel lines

- Primary fuel filter/water separator

- Siphon break

- Exhaust system components

- Insulated electrical system

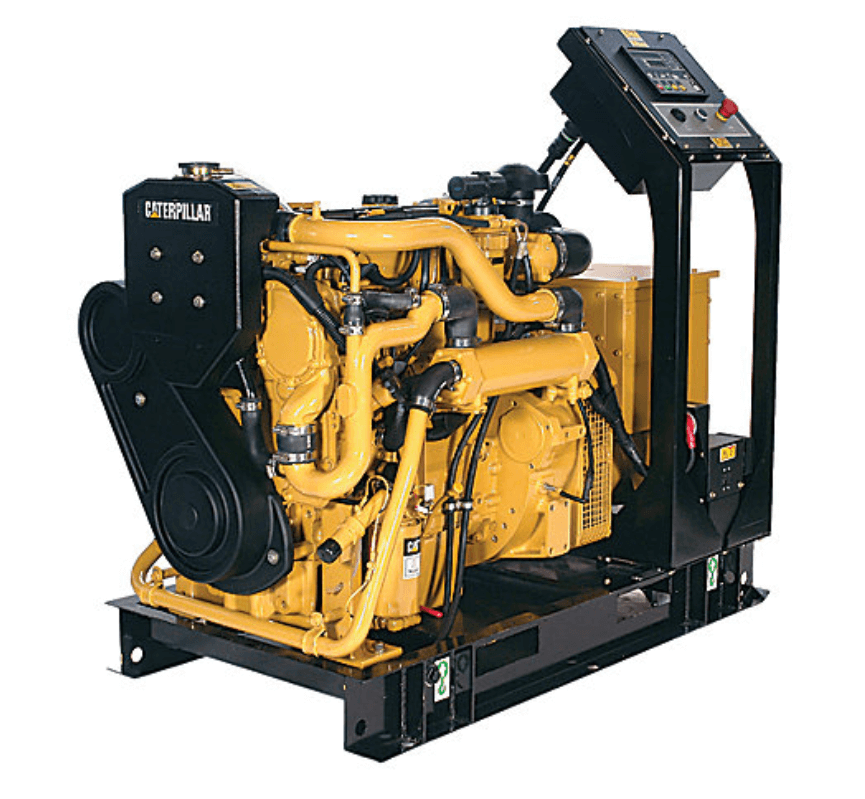

Caterpillar Engine 38 – Marine Generator Sets C4.4

KEY SPECS

Minimum Rating

36.0R ekW (45 kVA)

Maximum Rating

99 ekW (123 kVA)

Frequency

50 Hz or 60 Hz

Overview

Cat® C4.4 Diesel Marine Generator Set has three phase ratings of 50 Hertz at 38.0, 51.5, and 69.0 ekW with heat exchanger cooling and at 36.0, 49.0, and 65.0 ekW with radiator cooling that meet EU CCNR2 emissions standards. The C4.4 also has three phase ratings of 60 Hertz at 44.0, 58.5, 76.0, and 99.0 ekW with heat exchanger cooling and of 42.0, 56.0, 72.0, and 95.0 ekW with radiator cooling. C4.4 gen set is available in 12 or 24 volt as an open gen set or as an enclosed package. Single-side servicing improves ease of maintenance and lowers overall owner operating costs. The compact package size is ideal for a wide range of commercial and pleasure craft applications. These ratings also have Marine Classification Society approved packages available.

Key Features and Benefits:

- Economical: Low owning and operating costs with competitive pricing, longlife construction, and extended service intervals

- Easy to Install: Plug and play remote instrument panels

- Environmentally Responsible: Low emission, noise, and vibration levels; 60 Hz meets EPA Tier 2, 50 Hz meets EU 97/68EC Stage II regulations

- Safe: Automatic shutdowns for overspeed, high fresh water temperature, low engine oil pressure, and high exhaust temperature (when fitted with a wet exhaust system).

- Flexible: Available as an open set or with sound attenuated enclosure, and with radiator-, heat exchanger-, or keel-cooled options

- Excellent Power Quality: Suitable for sophisticated on-board equipment (computers, etc.)

- Single Source of Supply for Propulsion and Generator Sets: Reduced service costs and port time

PRODUCT SPECIFICATIONS FOR C4.4

GENERATOR SET SPECIFICATIONS

Minimum Rating | 36.0R ekW (45 kVA) |

Maximum Rating | 99 ekW (123 kVA) |

Frequency | 50 Hz or 60 Hz |

Speed | 1500 rpm or 1800 rpm |

Emissions/Fuel Strategy | EPA Tier 2 (60 Hz), EU 97/68EC Stage II (50 Hz) |

ENGINE SPECIFICATIONS

Engine Model | In-line 4, 4-Stroke-Cycle Diesel |

Aspiration | NA, T, TA |

Bore | 4.13 in |

Stroke | 5 in |

Displacement | 269 in³ |

Governor Type | Electronic |

GENERATOR SPECIFICATIONS

Excitation | Separately excited from auxiliary winding to provide 300% short circuit current up to 10 seconds |

Pitch | 2/3 |

Number of Leads | 12 lead reconnectable |

Insulation | Class H |

IP Rating | IP23 water protection (IP44 available for certain models, contact your dealer for information) |

Voltage Regulator | Solid state voltage regulator with integral voltage adjustment potentiometer |

GENERATOR SET DIMENSIONS

Length | 68.9 in |

Width | 47.8 in |

Height | 39.4 in |

Weight | 805 kg (1775 lb) – 1015 kg (2338 lb) |

C4.4 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Air cleaner, single element canister type w/ service indicator and rain cap

- Dry insulated turbocharger (DIT and DITA models only)

- Glowplug cold start system

COOLING SYSTEM

- Heat exchanger cooled packages w/ Cupro-nickel tube bundle (sized for 50 o C ambient air and 32 o C sea water) or Keel cooled packages (sized for 50 o C ambient air)

- De-aeration expansion tank

- Plate-type engine oil cooler

- Gear driven centrifugal jacket water pump

- Gear driven self priming sea water pump

- Caterpillar Extended Life Coolant (heat exchanger cooled packages)

EXHAUST SYSTEM

- Dry insulated turbocharger

- Water-cooled exhaust manifolds

FUEL SYSTEM

- Primary fuel filter / water separator w/ NPT and BSP connectors (ship loose)

- Secondary fuel filter (LH)

- Fuel priming pump electric

- Energize to run shutoff solenoid

GENERATOR

- 12 lead reconnectable

- 3 phase all models

- Brushless

- Separately excited from auxiliary winding to provide 300% short circuit current up to 10 seconds

- 2/3 pitch

- Broad voltage band

- IP23 water protection

- Solid state voltage regulator w/ integral voltage adjustment potentiometer

- Class H insulation

- Connection poles

LUBE SYSTEM

- Lubricating oil

- Oil filter (LH)

- Dipstick (LH)

- Fumes disposal (closed system)

MOUNTING SYSTEM

- Steel base frame with drip pan

- Anti-vibration mounts

STARTING/CHARGING SYSTEM

- Negative isolated ground electric system

GENERAL

- Single side service (LH)

- Keel cooled gensets do not include the keel cooler(s)

C4.4 OPTIONAL EQUIPMENT

SPACE HEATER KIT

- 240V AC, 120V AC

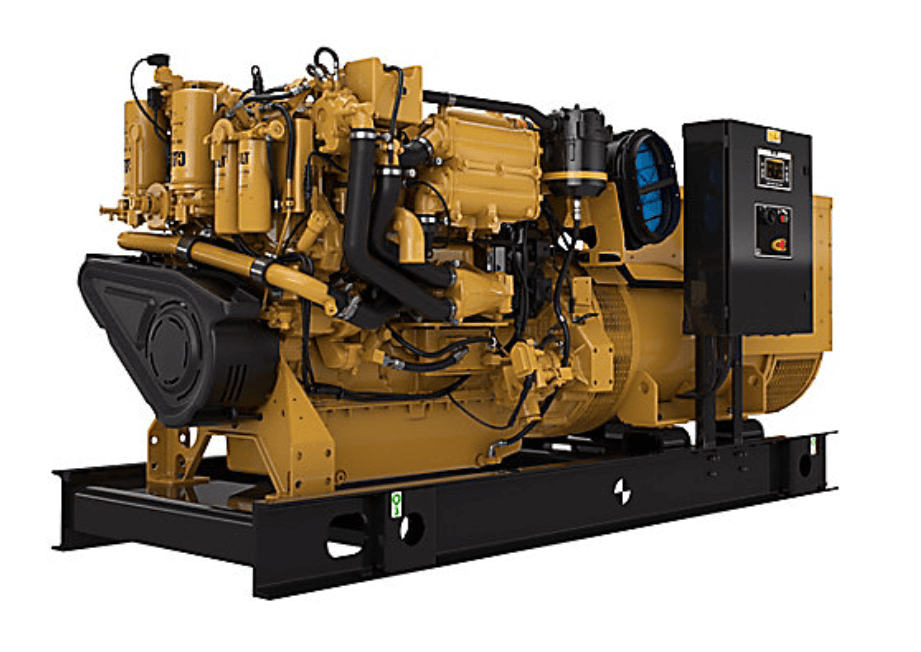

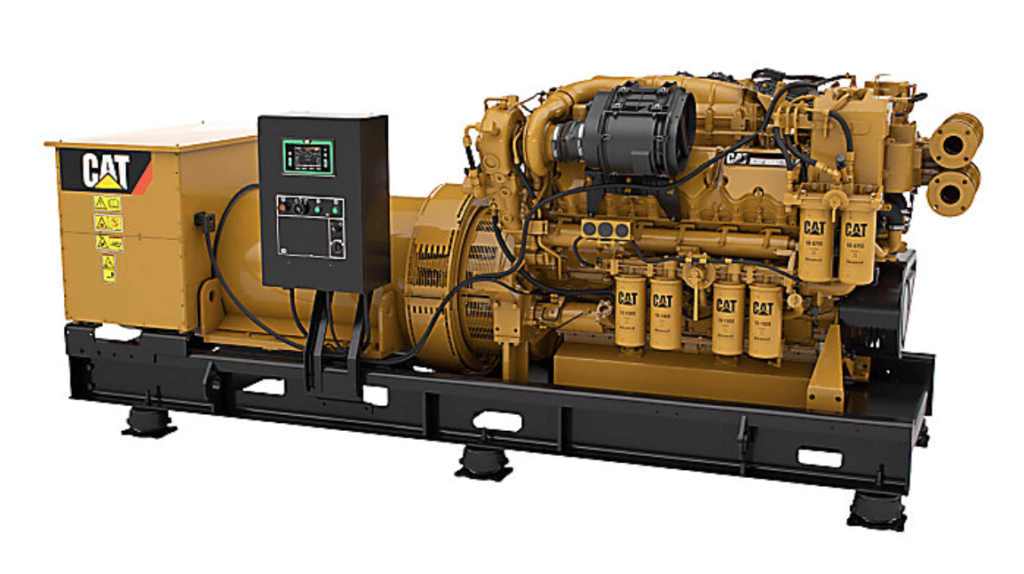

Caterpillar Engine 39 – Marine Generator Sets C7.1 (ELECTRONIC CONTROL SYSTEM)

KEY SPECS

Maximum Rating

100 ekW – 200 ekW (125 kVA – 250 kVA)

Speed

1,500 rpm / 1,800 rpm

Emissions

IMO II, IMO III (SCR required) U.S. EPA Tier 4, EU Stage V, China II

Overview

C7.1 (Electronic Control System)

Key Features & Benefits

- Gear Driven Water Pumps

- Automatic Valve Adjustment

- Variety of Different Cooling Systems

- Multiple Control Panel Options

- Engine Mounted Filtration

- Independent Shutdown Sensors and Controller

- Generator Paralleling Droop Kit for Load Sharing

- Streamlined Options for Easy Installation and Maintenance

- Utilizes SCR technology enabling IMO III emissions compliance (optional)

PRODUCT SPECIFICATIONS FOR C7.1 (ELECTRONIC CONTROL SYSTEM)

GENERATOR SET SPECIFICATIONS

Maximum Rating | 100 ekW – 200 ekW (125 kVA – 250 kVA) |

Speed | 1,500 rpm / 1,800 rpm |

ENGINE SPECIFICATIONS

Emissions | IMO II, IMO III (SCR required) U.S. EPA Tier 4, EU Stage V, China II |

Configuration | Inline 6, 4-Stroke Cycle Diesel |

Displacement | 428 in³ |

Aspiration | Turbocharged / Aftercooled |

Governor | Electronic (A5 ECM) |

Bore | 4.13 in |

Stroke | 5.31 in |

Refill Capacity | Lube Oil System w/oil filter change: 21 L / 5.6 gal |

Oil Change Interval | 500 hrs |

Rotation from Flywheel End | Counterclockwise |

Cooling | Heat exchanger, Seperate Circuit Keel Cooled, Combined Circuit Keel Cooled, Radiator Cooled |

GENERATOR SET DIMENSIONS

Length | 76.3 in /1,940 mm |

Height | 49.7 in / 1,263 mm |

Engine Dry Weight | 3355 lb / 1,522 kg |

Width | 38 in / 965 mm |

NOTE: GENERATOR SET DIMENSIONS AND WEIGHTS – DEPENDENT ON GENERATOR TYPE

C7.1 (ELECTRONIC CONTROL SYSTEM) STANDARD EQUIPMENT

STANDARD EQUIPMENT

- Common Rail Fuel System

- Mounted Air Cleaner

- Integral Plate Type Oil Cooler

- Isolated Sump

- Anti-vibration Mounts

- Gear Driven Sea Water Pump

- Gear Driven Jacket Water Pump

- Safety Shutdowns

- Water Cooled Exhaust Manifold

- Watercooled Turbocharger

C7.1 (ELECTRONIC CONTROL SYSTEM) OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- Marine Classification Society (MCS) Approval

- Generator Space Heater

- Engine Jacket Water Heater

- Duplex Oil Filters

- Duplex Fuel Filters

- Double Wall High Pressure Fuel Lines

- Additional Starter Motor

- Fuel Cooler (Radiator cooled only)

- Charging Alternator

- PTO Drive

- Service Parts Kit

- Generator Droop Kit

- Glow Plugs to Aid Cold Weather Starting

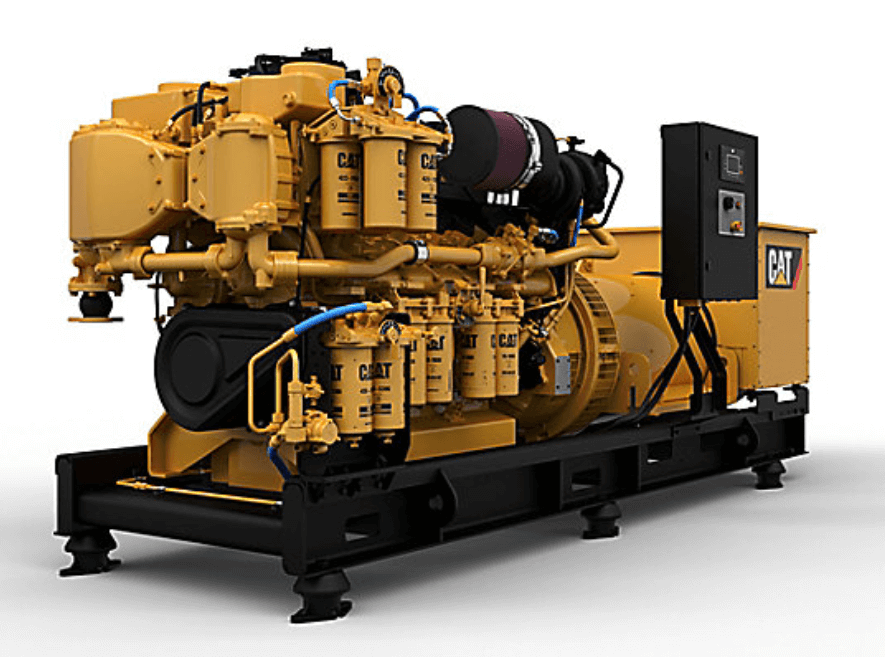

Caterpillar Engine 40 – Marine Generator Sets C9.3 MARINE GENERATOR SET

KEY SPECS

Speed

200 ekW – 274 ekW

Rated Engine Speed

1,500, 1,800 rpm

Emissions/Fuel Strategy

IMO II, IMO III, U.S. EPA Tier 3, China Stage II

Overview

C9.3 Marine Generator Set

Key Features & Benefits

- Electronic control system provides industry-leading torque and throttle response at low speeds, while maintaining fuel efficiency at high speeds

- Common rail fuel system enables optimum combustion and low emissions

- RH and LH locations service options for fuel and oil filters, as well as dipstick location for easily accessible service

- Compatible with Cat® displays

- Available remote-mounted display panel with start, stop, and engine diagnostics

- 12V or 24V electrical system

- Certified by all marine classification societies

- Utilizes SCR technology enabling IMO III emissions compliance while lowering operational costs

PRODUCT SPECIFICATIONS FOR C9.3 MARINE GENERATOR SET

GENERATOR SET SPECIFICATIONS

Speed | 200 ekW – 274 ekW |

Emissions/Fuel Strategy | IMO II, IMO III, U.S. EPA Tier 3, China Stage II |

ENGINE SPECIFICATIONS

Rated Engine Speed | 1,500, 1,800 rpm |

Aspiration | Turbocharged-aftercooled |

Bore | 4.5 in |

Stroke | 5.8 in |

Cooling | Heat exchanger and separate or combined keel cooled options |

Displacement | 567.5 in |

Oil Change Interval | 500 hrs |

Configuration | Inline 6, 4-Stroke Cycle diesel |

Refill Capacity | Lube Oil System w/oil filter change: 24.5 L (6.5 gal) |

Governor | Electronic |

Rotation from Flywheel End | Counterclockwise |

GENERATOR SET DIMENSIONS

Width | 38.5 in / 978 mm |

Length | 57.2 in / 1,452 mm |

Engine Dry Weight | 2083 – 2474 lb / 945 – 1122 kg |

Height | 43 in / 1,093 mm |

C9.3 MARINE GENERATOR SET STANDARD EQUIPMENT

STANDARD EQUIPMENT

- Water-cooled turbocharger and exhaust manifold

- Electronic control system

- Thermostats and housing

- Gear-driven Sea water pump (self-priming)

- Common rail fuel system

- Shell and tube jacket water heat exchanger

- Corrosion-resistant Sea water aftercooler

- Engine oil cooler

- Vibration damper and guard

- Primary fuel filters

C9.3 MARINE GENERATOR SET OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- Alternators – 24V 70 or 105 amp, 12V 110 amp

- Closed crankcase ventilation

- Transmission gear oil cooler (engine mounted for HEX)

- Additional engine and transmission sensor packages

- Instrument panels

- Electric starting motors – 12V or 24V

- Air starting motor

- Dual electric starting motors or combined electric/air

- Electric fuel priming pump

- Fuel cooler

- PTO Drives – V-belt pulley stack, stub shaft

- Duplex fuel and oil filters

- Double wall fuel rail

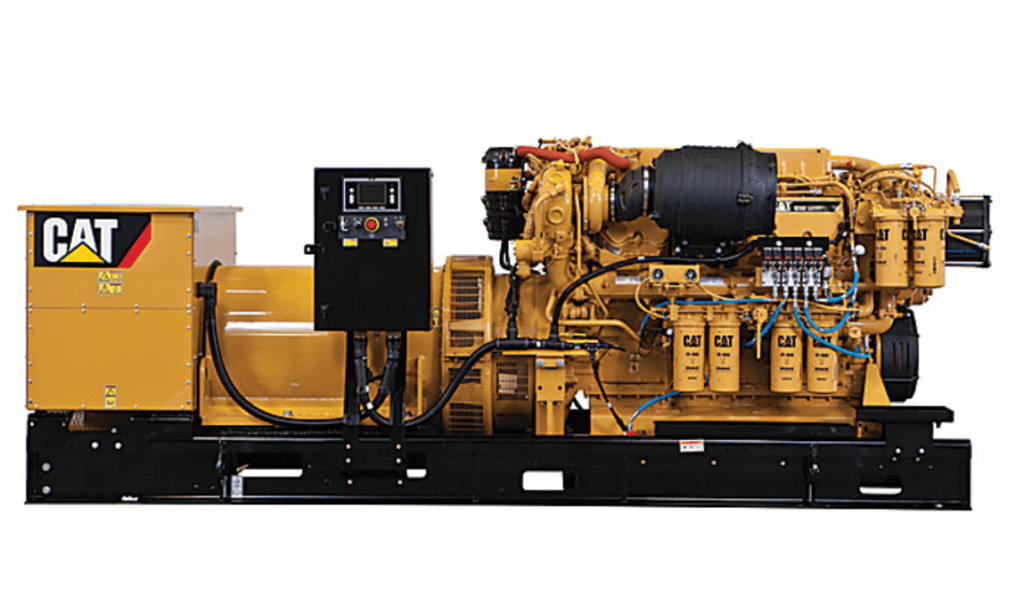

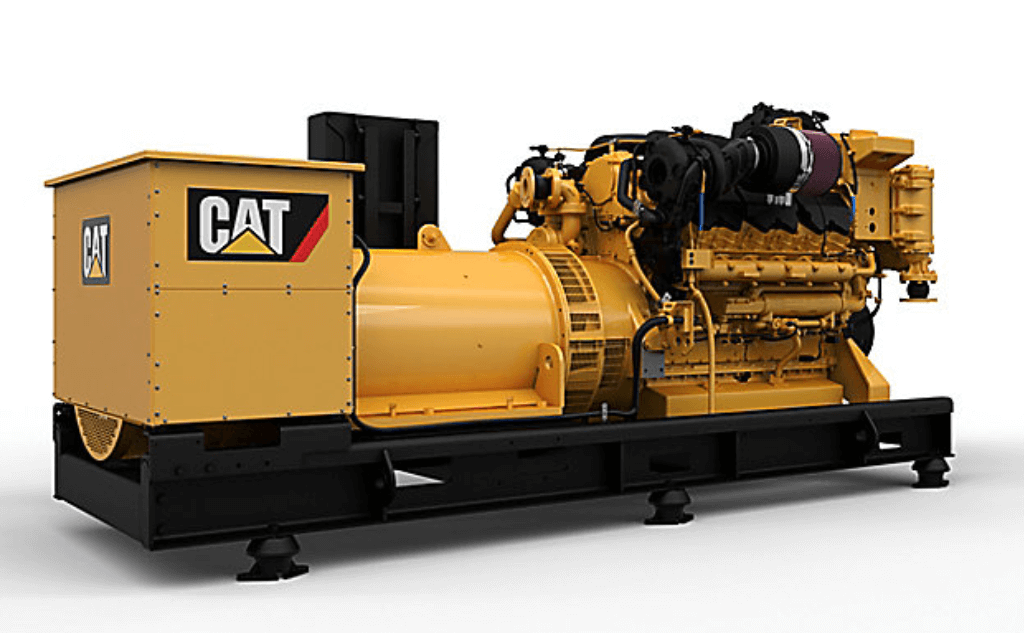

Caterpillar Engine 41 – Marine Generator Sets C18 (SRMP) MARINE GENERATOR SET

KEY SPECS

Minimum Rating

260 ekW (325 kVA)

Maximum Rating

565 ekW (706 kVA)

Frequency

50 hz

Overview

The C18 SRMP is the latest generator and brings commonality with our petroleum products as well as interfacing improvements. We have also taken this opportunity to add new price list options. All engine ratings and emissions certifications are the same, however we have been able to increase the power output of the generator for 12 of the 14 ratings.

Key Features and Benefits:

- Separate Circuit Aftercooling System: The primary advantage of the separate circuit aftercooling system (SCAC) is that no sea water circulates through the aftercooler

- Emissions: EPA Tier 3 compliant, IMO II and EU IWW compliant

- Cooling System: Heat exchanger and Keel cooled options for all ratings

- Turbo Configurations: Single turbo configurations for all ratings

- Competitive Size and Weight:

- Marine Certifications: All major MCS type approvals available from factory

PRODUCT SPECIFICATIONS FOR C18 (SRMP) MARINE GENERATOR SET

GENERATOR SET SPECIFICATIONS

Minimum Rating | 260 ekW (325 kVA) |

Maximum Rating | 565 ekW (706 kVA) |

Frequency | 50 hz |

Speed | 50 Hz – 1500 rpm, 60 Hz – 1800 rpm |

GENERATOR SET CONFIGURATIONS

Emissions | EPA Tier 3, IMO II, EU IW |

ENGINE SPECIFICATIONS

Configuration | In-line 6, 4-Stroke-Cycle Diesel |

Aspiration | Turbocharged – aftercooled |

Bore | 5.7 in |

Stroke | 7.2 in |

Fuel System | MEUI |

GENERATOR SPECIFICATIONS

Excitation | SRMP |

Insulation | Class H |

IP Rating | IP23 (standard), IP 44 (optional) |

Voltage Regulator | CDVR (Digital Voltage) |

GENERATOR SET DIMENSIONS – RADIATOR COOLED

Height | 94.8 in |

Length | 55.6 in |

Width | 66.9 in |

Weight – Approximate | 13396 lb |

GENERATOR SET DIMENSIONS – KEEL AND HEX COOLED

Length | 119.6 in |

Height | 64.9 in |

Width | 55.6 in |

Weight – Approximate | 9747 lb |

C18 (SRMP) MARINE GENERATOR SET STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Heavy-duty inlet air filter

COOLING SYSTEM

- SCAC pump, gear driven, for HEX cooled engines only

- Jacket water pump, gear driven

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- Round flanged exhaust outlet

FUEL SYSTEM

- Hybrid fuel lines

- MEUI™ fuel system

- Fuel filter, front service

- Fuel transfer and priming pumps

LUBE SYSTEM

- Center sump oil pan, deep

- Front and top service oil filler locations

- Front service dipstick

MOUNTING SYSTEM

- Vibration Isolators

- Formed C-channel rails

CONTROL SYSTEM

- Electronic fuel/air ratio control

- SRMP permanent magnet 12-lead generator

- Digital voltage regulator

- Class H insulation, Class F temperature rise, IP23 protection

C18 (SRMP) MARINE GENERATOR SET OPTIONAL EQUIPMENT

EXHAUST SYSTEM

- Dry Elbows

- Water-Cooled Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler, Spark Arresting

- Fumes disposal (closed system)

AIR INLET SYSTEM

- Air Inlet Adapter

CHARGING SYSTEM

- Battery Chargers 10 amp

- Battery sets: 24V 950-1300 CCA

- Charging alternator 24V 105 amp

CONTROL SYSTEM

- Caterpillar alarm and protection

- EMCP 4.2 control panel

- MGCP III B control panel

FUEL SYSTEM

- Duplex fuel filter – front service

- Fuel cooler

- Primary fuel/water separator

INSTRUMENTATION

- Generator service side – LH, RH

- Generator terminal box extension

- Load sharing module (option for type approved module)

LUBE SYSTEM

- Spare pump kits

- Duplex oil filter – front service

- Manual sump pump

MOUNTING SYSTEM

- Vibration Isolators

PROTECTION SYSTEM

- Generator protection – IP44

STARTING SYSTEM

- Starting motors – electric and/or air

- Jacket water heaters

Caterpillar Engine 42 – Marine Generator Sets C32 ACERT IMO II

KEY SPECS

Minimum Rating

550 eKW (688 kVA)

Maximum Rating

940 ekW (1175 kVA)

Frequency

50 Hz or 60 Hz

Overview

C32 ACERT generator sets incorporate a separate circuit aftercooling system (SCAC) for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines contribute to minimizing owning and operating costs. The IMO II and EU Stage IIIA compliant ratings are available with heat exchanger or keel cooled options. Heat exchanger configurations have an optional front mounted sea water pump.

Key Features and Benefits

- Emissions: IMO II comlpliant

- Worldwide Support: Extensive service network of dealers; Unparalleled service from authorized marine dealers.

- Durability: Proven engine operating history; Performance iron with thousands of hours of validation testing for quality and durability.

- Reliability: 60 months standard warranty

- Cooling System: Heat Exchanger or Keel Cooling; Heat exchanger configurations: optional front mounted sea water pump

- Aftercooling System: Separate circuit aftercooling system (SCAC): no seawater circulating through the aftercooler

PRODUCT SPECIFICATIONS FOR C32 ACERT IMO II

GENERATOR SET SPECIFICATIONS

Minimum Rating | 550 eKW (688 kVA) |

Maximum Rating | 940 ekW (1175 kVA) |

Frequency | 50 Hz or 60 Hz |

Speed | 1500 rpm (50 hz) or 1800 rpm (60 hz) |

Emissions/Fuel Strategy | IMO II |

ENGINE SPECIFICATIONS

Aspiration | Twin Turbocharged-Aftercooled |

Bore | 5.7 in |

Stroke | 6.4 in |

Displacement | 1959 in³ |

Governor Type | Electronic |

Fuel System | Diesel |

Engine Model | Vee 12, 4-Stroke-Cycle Diesel |

GENERATOR SPECIFICATIONS

Excitation | permanent magnet (PMG) |

Pitch | 2/3 |

Number of Poles | 4 |

Number of Bearings | 2 roller bearings |

Number of Leads | 6 |

Insulation | Class H |

Voltage Regulation | ± 0.5% (steady state) |

Frame Size | 1423, 1467 |

IP Rating | Drip Proof IP 23* |

Alignment | Closed-coupled adapter |

Wave Form Deviation – Line to Line | < 3.0% |

Voltage Regulator | Cat® Digital Voltage Regulator (CDVR) |

Telephone Influence Factor (TIF) | < 50 |

GENERATOR SET DIMENSIONS

Length | 168.34 in |

Width | 65.79 in |

Height | 70.86 in |

Weight – Estimated | 15721 lb |

C32 ACERT IMO II STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- If an EMCP panel or MGCP option is not chosen as optional equipment, then start/stop controls must be provided by the customer

- Electronic diagnostics and fault logging

- Engine Protection Mode for extended ambient conditions

- Electronic fuel/air ratio control

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for Heat Exchanged (HEX) & Keel cooled engines

- Jacket Water (JW) and SCAC Heat Exchangers Shell & Tube for HEX cooled engines

- SCAC pump, gear driven

- Jacket water pump, gear driven

- Sea water pump, bronze impeller, gear driven, for HEX cooled engines only

- Jacket water HEX with Sea water pump Connections: 76.2 mm (3in) ID Standard

- 4 Bolt ANSI Flange Connection

- Jacket water HEX without Sea water pump Connection: 2.5″ hose barb connection (inlet), 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange (outlet)

- Keel Connections: 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange Connection

- SCAC and JW shunt tanks for maintaining proper Pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 4 Bolt 130 mm (5.12 in) diameter flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

FUEL SYSTEM

- Duplex Fuel Filters, Spin-on, RH service

- Fuel connections size: Supply JIC Deg -10 (7/8 – 14), Return JIC 37 Deg -8 (3/4 -16)

- Plate-type fuel cooler installed behind Aftercooler Shunt Tank

- Fuel transfer pump, gear driven

- Manual fuel priming pump

GENERATORS AND GENERATOR ATTACHMENTS

- SR5 form wound

- 2 roller bearings

- Permanent magnet excitation

- 4 pole, 6 leads, Series Star connected

- Caterpillar’s Digital Voltage Regulator (CDVR)

- Marine Class H insulation, Class F temperature rise

- Surface mounted platinum (PT100) 3-wire RTDs, 2 per phase on stator and one each on support bearings

- Anti-condensation space heaters (2 elements – 240 VAC, 1000 Watts

- IP23 Protection suitable for use with Fixed Water Based Local Application Fire Fighting Systems (FWBLAFFS)

- System IV insulation for harsh environment protection

LUBE SYSTEM

- Simplex oil filters, RH service

- Deep sump oil pan

- RH service oil filler locations

- RH service dipstick

- Oil pump, gear driven

MOUNTING SYSTEM

- Formed C-channel rails, 300mm (11.81in) height

- Six shipped loose combined helical spring/rubber isolators for installation below package base

GENERAL

- Front damper guard

- Common electrical bonding point on HEX and KEEL cooled engines

C32 ACERT IMO II OPTIONAL EQUIPMENT

ALARM AND PROTECTION

- Remote Panels

- MCS Controller

- Power analyzer module

- oil level, exhaust temperature, air starting pressure, heat exchanger pressure sensors

EXHAUST SYSTEM

- Dry Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

- Rain Cap

AIR INLET SYSTEM

- Air Inlet Cleaner

- Closed Crankcase Ventilation

- Air inlet adapter

CHARGING SYSTEM

- Battery Chargers, Charging Alternators

CONTROL SYSTEM

- Load Sharing Attachment

FUEL SYSTEM

- Water Separator

LUBE SYSTEM

- Duplex Oil Filters, Sump Pump

PROTECTION SYSTEM

- Fuel and Oil Shielding

STARTING SYSTEM

- Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Dual Starting Motors (Electric and Air)

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

Caterpillar Engine 43 – Marine Generator Sets C32 ACERT TIER 3

KEY SPECS

Minimum Rating

730 ekW (913 kVA)

Maximum Rating

940 ekW (1175 kVA)

Frequency

60hz

Overview

C32 ACERT generator sets incorporate a separate circuit aftercooling system (SCAC) for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines contribute to minimizing owning and operating costs. The EPA Tier 3, IMO II, EU Stage IIIA compliant ratings are available with heat exchanger or keel cooled options. Heat exchanger configurations have an optional front mounted sea water pump.

Key Features and Benefits

- Emissions: U.S. EPA Tier 3 compliant

- Worldwide Support: Extensive service network of dealers; Unparalleled service from authorized marine dealers

- Durability: Proven engine operating history; Performance iron with thousands of hours of validation testing for quality and durability

- Reliability: 60 months standard warranty

- Cooling System: Heat Exchanger or Keel Cooling; Heat exchanger configurations: optional front mounted sea water pump

- Aftercooling System: Separate circuit aftercooling system (SCAC): no seawater circulating through the aftercooler

PRODUCT SPECIFICATIONS FOR C32 ACERT TIER 3

GENERATOR SET SPECIFICATIONS

Minimum Rating | 730 ekW (913 kVA) |

Maximum Rating | 940 ekW (1175 kVA) |

Frequency | 60hz |

Speed | 1800 rpm |

Emissions/Fuel Strategy | EPA Tier III |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged and aftercooled |

Bore | 5.7 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Governor Type | Electronic |

Fuel System | MEUI |

Engine Model | Vee-12, 4-stroke-Cycle-Diesel |

GENERATOR SPECIFICATIONS

Excitation | Permanent magnet |

Number of Poles | 4 |

Number of Bearings | 2 roller bearings |

Number of Leads | 6 |

Insulation | Class H |

IP Rating | 23 |

Voltage Regulator | CDVR |

GENERATOR SET DIMENSIONS

Width | 60.2 in |

Height | 65.6 in |

Weight – Estimated | 15721 lb |

Length | 162.8 in/4271 mm (minimum), 175.3 in/4452 mm (maximum) |

C32 ACERT TIER 3 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- If an EMCP panel or MGCP option is not chosen as optional equipment, then start/stop controls must be provided by the customer

- Electronic diagnostics and fault logging

- Engine Protection Mode for extended ambient conditions

- Electronic fuel/air ratio control

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for Heat Exchanged (HEX) & Keel cooled engines

- Jacket Water (JW) and SCAC Heat Exchangers Shell & Tube for HEX cooled engines

- SCAC pump, gear driven

- Jacket water pump, gear driven

- Sea water pump, bronze impeller, gear driven, for HEX cooled engines only

- Jacket water HEX with Sea water pump Connections: 76.2 mm (3in) ID Standard

- 4 Bolt ANSI Flange Connection

- Jacket water HEX without Sea water pump Connection: 2.5″ hose barb connection (inlet), 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange (outlet)

- Keel Connections: 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange Connection

- SCAC and JW shunt tanks for maintaining proper Pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 4 Bolt 130 mm (5.12 in) diameter flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

FUEL SYSTEM

- Duplex Fuel Filters, Spin-on, RH service

- Fuel connections size: Supply JIC 37 Deg -10 (7/8-14), Return JIC 37 Deg -8 (3/4-16)

- Plate-type fuel cooler installed behind Aftercooler Shunt Tank

- Fuel transfer pump, gear driven

- Manual fuel priming pump

GENERATORS AND GENERATOR ATTACHMENTS

- SR5 form wound

- 2 roller bearings

- Permanent magnet excitation

- 4 pole, 6 leads, Series Star connected

- Caterpillar’s Digital Voltage Regulator (CDVR)

- Marine Class H insulation, Class F temperature rise

- Surface mounted platinum (PT100) 3-wire RTDs, 2 per phase on stator and one each on support bearings

- Anti-condensation space heaters (2 elements – 240 VAC, 1000 Watts

- IP23 Protection suitable for use with Fixed Water Based Local Application Fire Fighting Systems (FWBLAFFS)

- System IV insulation for harsh environment protection

LUBE SYSTEM

- Simplex oil filters, RH service

- Deep sump oil pan

- RH service oil filler locations

- RH service dipstick

- Oil pump, gear driven

MOUNTING SYSTEM

- Formed C-channel rails, 300mm (11.81in) height

- Six shipped loose combined helical spring/rubber

- isolators for installation below package base

GENERAL

- Front Damper guard

- Common electrical bondng point on HEX and KEEL cooled engines

C32 ACERT TIER 3 OPTIONAL EQUIPMENT

ALARM AND PROTECTION

- Remote panels

- MCS Controller

- Power analyzer module

- Oil level, exhaust temperature, air starting pressure, heat exchanger pressure sensors

EXHAUST SYSTEM

- Dry Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

- Rain Cap

AIR INLET SYSTEM

- Air Inlet Cleaner

- Closed Crankcase Ventilation

- Air inlet adapter

CHARGING SYSTEM

- Battery Chargers, Charging Alternators

CONTROL SYSTEM

- Load Sharing Attachment

FUEL SYSTEM

- Water Separator

LUBE SYSTEM

- Duplex Oil Filters, Sump Pump

PROTECTION SYSTEM

- Fuel and Oil Shielding

STARTING SYSTEM

- Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Dual Starting Motors (Electric and Air)

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

Caterpillar Engine 44 – Marine Generator Sets C32 TIER 3 / IMO II

KEY SPECS

Minimum Rating

219 ekW

Maximum Rating

940 ekW

Frequency

60hz

Overview

Cat C32 Generator Set (US EPA Tier 3 / IMO II)

Key Features and Benefits

- Scac: Separate-circuit aftercooling – no sea water in aftercooler

- Fuel System: Reliable electronic controlled unit injector fuel system. Enhanced control of fuel injection optimized through crank timing and A4 ECM technology. Advanced combustion technology to optimize fuel consumption and meet emissions without aftertreatment.

- Power Reserve: Industry leading power reserve

- Certifications: Wide range of available Marine Society certifications

- Warranty: Industry-leading warranty coverage for factory packaged components

- Service: Global dealer network for service in any location

PRODUCT SPECIFICATIONS FOR C32 TIER 3 / IMO II

GENERATOR SET SPECIFICATIONS

Minimum Rating | 219 ekW |

Maximum Rating | 940 ekW |

Frequency | 60hz |

GENERATOR SET DIMENSIONS

Length | 167.2 in/4245 mm (minimum), 226.1 in/5742 mm (maximum) |

Width | 59.9 in/1521 mm (minimum), 89.8 in/2280 mm (maximum) |

Height | 70.4 in/1747 mm (minimum), 92.8 in/2356 mm (maximum) |

Package Dry Weight | 15721 lb/7131 kg (minimum), 21998 lb/9978 kg (maximum) |

ENGINE SPECIFICATIONS

Configuration | Vee-12, 4-stroke-Cycle-Diesel |

Aspiration | Turbocharged-aftercooled aspiration |

Bore | 5.71 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Emissions | U.S. EPA Tier 3 / IMO II emissions certified |

Rated Engine Speed | 1800 rpm |

Governor | Electronic (A4 ECM) |

Generator | SR5 – Form Wound |

Refill Capacity | Lube Oil System w/ oil filter change: 146 L (38.5 gal) |

Cooling | Heat exchanger, keel or radiator cooled |

Oil Change Interval | 750 hrs |

C32 TIER 3 / IMO II STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooled (SCAC)

CONTROL SYSTEM

- 24V control system

COOLING SYSTEM

- Heat exchanger, keel or radiator cooled

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

FUEL SYSTEM

- Duplex fuel filters with hybrid fuel lines

- Fuel transfer and priming pump

GENERATORS AND GENERATOR ATTACHMENTS

- IP23, air cooled, form wound SR5 generator offered in 440, 480 and 690V

LUBE SYSTEM

- Oil fill, simplex filter and dipstick

MOUNTING SYSTEM

- Helical spring/rubber isolated mounting for vibration and structure borne noise reduction

GENERAL

- Right or left hand service sides

- Customer wiring and service tool connector

C32 TIER 3 / IMO II OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Closed crankcase ventilation

ALARM AND PROTECTION

- MGCP II or MGCP IIIB control panel with Cat® alarm and protection system

- IP44 generator protection

EXHAUST SYSTEM

- Muffler

- SOLAS approved spray shielding

CHARGING SYSTEM

- Charging alternator

CONTROL SYSTEM

- EMCP 4.2 control panel

FUEL SYSTEM

- Installed primary fuel filter with water separator and manual or electric priming pump

- Fuel cooler

LUBE SYSTEM

- Duplex oil filters

STARTING SYSTEM

- Starting motors – air, electric or dual

Caterpillar Engine 45 – Marine Generator Sets C32 IMO III

KEY SPECS

Minimum Rating

219 ekW

Maximum Rating

940 ekW

Frequency

60hz

Overview

Cat C32 Generator Set, IMO III emissions certified (SCR required)

Key Features and Benefits

- Emissions: Utilizes SCR Technology to enable IMO III emission regulations compliance while lowering operational costs

- Control Strategy: Utilizes closed loop air assisted DEF dosing control strategy that delivers: Highest efficiency mixing and control to lower operational costs; Extends emissions useful life; Ensures compliance; Flexible to urea quality

- Fuel System: Enhanced control of fuel injection optimized through crank timing and the A5 ECM technology

- Power Reserve: Industry-leading power reserve

- Certifications: Wide range of available Marine Society certifications

- Warranty: Industry-leading warranty coverage for factory packaged components

- Service: Global dealer network for service in any location

PRODUCT SPECIFICATIONS FOR C32 IMO III

GENERATOR SET SPECIFICATIONS

Minimum Rating | 219 ekW |

Maximum Rating | 940 ekW |

Frequency | 60hz |

GENERATOR SET DIMENSIONS

Length | 167.2 in/4245 mm (minimum), 226.1 in/5742 mm (maximum) |

Width | 59.9 in/1521 mm (minimum), 89.8 in/2280 mm (maximum) |

Height | 70.4 in/1747 mm (minimum), 92.8 in/2356 mm (maximum) |

Package Dry Weight | 15721 lb/7131 kg (minimum), 21998 lb/9978 kg (maximum) |

ENGINE SPECIFICATIONS

Configuration | Vee-12, 4-stroke-Cycle-Diesel |

Aspiration | Turbocharged-aftercooled aspiration |

Bore | 5.71 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Emissions | IMO III emissions certified (SCR required) |

Rated Engine Speed | 1500 rpm |

Governor | Electronic (A5 ECM) |

Refill Capacity | Lube Oil System w/ oil filter change: 146 L (38.5 gal) |

Oil Change Interval | 750 hrs |

Cooling | Heat exchanger, keel or radiator cooled |

Generator | SR5 – Form Wound |

C32 IMO III STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooled (SCAC)

- Closed crankcase fumes disposal

CONTROL SYSTEM

- 24V control system

COOLING SYSTEM

- Heat exchanger or Keel Cooling

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

FUEL SYSTEM

- Primary fuel filter with water separator installed on base frame

- Duplex fuel filters with hybrid fuel lines

GENERATORS AND GENERATOR ATTACHMENTS

- IP23, air cooled, form wound SR5 generator offered in 380, 400, 415 and 690 V

LUBE SYSTEM

- Oil fill, simplex filter and dipstick

MOUNTING SYSTEM

- Helical spring/rubber isolated mounting for vibration and structure borne noise reduction

GENERAL

- Right or left hand service sides

- Customer wiring and service tool connector

C32 IMO III OPTIONAL EQUIPMENT

ALARM AND PROTECTION

- MGCPIIIB control panel with Cat® Alarm and Protection System

- IP44 generator protection

EXHAUST SYSTEM

- Muffler

- Water-in-fuel and exhaust temperature sensors

- SOLAS approved spray shielding

CHARGING SYSTEM

- Charging alternator

FUEL SYSTEM

- Manual or electric fuel priming pump

- Fuel cooler

LUBE SYSTEM

- Duplex oil filters

STARTING SYSTEM

- Starting motors – air, electric or redundant

Caterpillar Engine 46 – Marine Generator Sets C32 TIER 4 / IMO III

KEY SPECS

Minimum Rating

282 ekW

Maximum Rating

940 ekW

Frequency

60hz

Overview

Cat C32 Generator Set (US EPA Tier 4 / IMO III)

Key Features and Benefits

Emissions: Utilizes SCR Technology to enable U.S. EPA Tier 4 Final and IMO III emission regulations compliance while lowering operational costs

Control Strategy: Utilizes closed loop air assisted DEF dosing control strategy that delivers: Highest efficiency mixing and control to lower operational costs ; Extends emissions useful life ; Ensures compliance ; Flexible to urea quality

Fuel System: Enhanced control of fuel injection optimized through crank timing and the A5 ECM technology

Power Reserve: Industry leading power reserve

Certifications: Wide range of available Marine Society certifications

Warranty: Industry-leading warranty coverage for factory packaged components

Service: Global dealer network for service in any location

PRODUCT SPECIFICATIONS FOR C32 TIER 4 / IMO III

GENERATOR SET SPECIFICATIONS

Minimum Rating | 282 ekW |

Maximum Rating | 940 ekW |

Frequency | 60hz |

GENERATOR SET DIMENSIONS

Length | 167.2 in/4245 mm (minimum), 226.1 in/5742 mm (maximum) |

Width | 59.9 in/1521 mm (minimum), 89.8 in/2280 mm (maximum) |

Height | 70.4 in/1747 mm (minimum), 92.8 in/2356 mm (maximum) |

Engine Dry Weight | 15721 lb/7131 kg (minimum), 21998 lb/9978 kg (maximum) |

ENGINE SPECIFICATIONS

Configuration | Vee-12, 4-stroke-Cycle-Diesel |

Aspiration | Turbocharged-aftercooled aspiration |

Bore | 5.71 in |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Emissions | U.S. EPA Tier 4 Final certified / IMO III emissions certified (SCR required) |

Rated Engine Speed | 1800 rpm |

Governor | Electronic (A5 ECM) |

Generator | SR5 – Form Wound |

Cooling | Heat exchanger, keel or radiator cooled |

Oil Change Interval | 750 hrs |

Refill Capacity | Lube Oil System w/ oil filter change: 146 L (38.5 gal) |

CLEAN EMISSIONS MODULE (CEM) – DIMENSIONS

6 Brick Z-Flow – Length | 147.7 in |

Dosing Cabinet – Weight | 209 lb |

6 Brick Z-Flow – Weight | 1246 lb |

6 Brick U-Flow – Weight | 1235 lb |

Dosing Cabinet – Height | 22.8 in |

6 Brick U-Flow – Width | 56.9 in |

6 Brick U-Flow – Length | 85 in |

Dosing Cabinet – Width | 18.8 in |

6 Brick Z-Flow – Width | 43.5 in |

6 Brick U-Flow – Height | 23.5 in |

Dosing Cabinet – Length | 37.4 in |

6 Brick Z-Flow – Height | 23.5 in |

C32 TIER 4 / IMO III STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooled (SCAC)

- Closed crankcase fumes disposal

CONTROL SYSTEM

- 24V control system

COOLING SYSTEM

- Heat exchanger or Keel Cooling

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

FUEL SYSTEM

- Duplex fuel filters with hybrid fuel lines

- Primary fuel filter with water separator installed on base frame

GENERATORS AND GENERATOR ATTACHMENTS

- IP23, air cooled, form wound SR5 generator offered in 440, 480 and 690V

LUBE SYSTEM

- Oil fill, simplex filter and dipstick

MOUNTING SYSTEM

- Helical spring/rubber isolated mounting for vibration and structure borne noise reduction

GENERAL

- Right or left hand service sides

- Customer wiring and service tool connector

C32 TIER 4 / IMO III OPTIONAL EQUIPMENT

ALARM AND PROTECTION

- MGCP III B control panel with Cat® Alarm and Protection System

- IP44 generator protection

EXHAUST SYSTEM

- Muffler

- Water-in-fuel and exhaust temperature sensors

- SOLAS approved spray shielding

CHARGING SYSTEM

- Charging alternator

FUEL SYSTEM

- Manual or electric fuel priming pump

- Fuel cooler

LUBE SYSTEM

- Duplex oil filters

STARTING SYSTEM

- Starting motors – air, electric or redundant

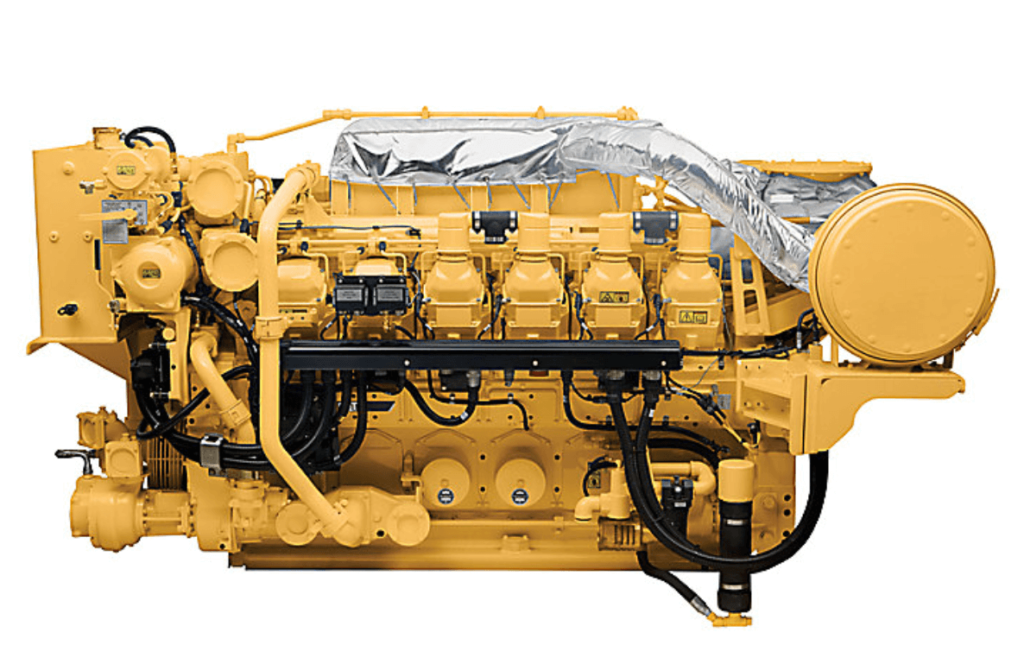

Caterpillar Engine 47 – Marine Generator Sets 3512C

KEY SPECS

Minimum Rating

1550 eKW (1937 kVA)

Maximum Rating

1700 eKW (2125 kVA)

Frequency

60 hz

Overview

3512C High Displacement Marine Generator Set

Key Features and Benefits

- Emissions Flexibility and Capability

- High Power Density

- Improved Reliability and Durability

- Medium Speed Bsfc and Reliability in a High-speed Product

PRODUCT SPECIFICATIONS FOR 3512C

GENERATOR SET SPECIFICATIONS

Minimum Rating | 1550 eKW (1937 kVA) |

Maximum Rating | 1700 eKW (2125 kVA) |

Frequency | 60 hz |

Speed | 1800 |

GENERATOR SET CONFIGURATIONS

Emissions | IMO II |

ENGINE SPECIFICATIONS

Configuration | Vee 12 4-Stroke-Cycle Diesel |

Aspiration | TTA |

Bore | 6.7 in |

Stroke | 8.46 in |

Displacement | 3574 in³ |

GENERATOR SET DIMENSIONS

Length | 200.2 in |

Width | 84.3 in |

Height | 83.9 in |

Weight – Estimated | 28136 lb |

3512C STANDARD EQUIPMENT

AIR INLET SYSTEM

- Corrosion resistant separate circuit aftercooler core, regular duty air cleaners, dual turbochargers

CONTROL SYSTEM

- Caterpillar A-III electronic engine control, Electronic Unit Injection fuel system, rigid wiring harness

COOLING SYSTEM

- Auxiliary fresh water pump, centrifugal non-self-priming auxiliary sea water pump, gear driven centrifugal jacket water pump, expansion tank, engine oil cooler, thermostats and housing

EXHAUST SYSTEM

- Dry gas-tight exhaust manifolds with heat shields, dual turbochargers with water-cooled bearings and heat shields, vertical exhaust outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel, SAE No. 00, 183 teeth Flywheel housing, SAE No. 00

FUEL SYSTEM

- Fuel filter, RH, with service indicators

- Fuel transfer pump

- Electronically Controlled Unit Injectors

INSTRUMENTATION

- Engine mounted instrument panel with four position switch, over speed shutdown notification light, emergency stop notification light, graphical display unit for analog or digital display of: oil and fuel pressure, oil and fuel filter differential, system DC voltage, exhaust and water temperature, air inlet restriction, service meter, engine speed, fuel consumption (total and instantaneous)

LUBE SYSTEM

- Top mounted crankcase breather, RH oil filter, RH oil filler, gear type oil pump, deep sump oil pan, recommended use of Caterpillar Diesel Engine Oil 10W30 or 15W40

MOUNTING SYSTEM

- Industrial type engine mounting rails)

POWER TAKE-OFFS

- Accessory drive Lower RH, Lower LH Front housing, Two-sided

PROTECTION SYSTEM

- A-III Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection for oil pressure and water temperature, over speed protection

GENERAL

- Vibration damper and guard Paint, Caterpillar Yellow engine with black rails. Lifting eyes

3512C OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Air Cleaner Removal

- Remote Air Inlet Adapters

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

CONTROL SYSTEM

- Load Sharing module

- Local speed throttle control

COOLING SYSTEM

- Water level switch gauge

- Coolant level sensors

- Connections

- Keel Cooling Conversions

- Radiator cooling conversion

- Heat exchangers

- Auxiliary water pumps

- Sea water pump removal

- Air separator

EXHAUST SYSTEM

- Exhaust outlet

- Flexible fittings

- Elbows

- Flanges

- Flange and exhaust expanders

- Mufflers

FUEL SYSTEM

- Fuel Cooler

- Fuel priming pumps

- Flexible fuel lines

- Rigid Fuel Lines

- Primary fuel filter

- Fuel level switch

GENERATORS AND GENERATOR ATTACHMENTS

- 1500/1800 RPM, 1000/1200 RPM

- Low Voltage Connection

- Generator Conversion

- Low Voltage Extension Box

- RFI Filter

- Bearing Temperature Detectors

- Manual Voltage Control

- Air Filter

INSTRUMENTATION

- PL1000T Communication Module

- PL1000E Communication Module

- Customer Interface Box

- Thermocouples

- Remote panel display

- Remote cylinder temperature display

LUBE SYSTEM

- Oil Pan

- Oil pan accessories

- Sump pumps

- Prelubrication Options

- Lubricating oil

- Centrifugal Oil Filter

MOUNTING SYSTEM

- Vibration isolators

- Rails

POWER TAKE-OFFS

- Flywheel guard

- Flexible coupling

- Coupling hub

- Front housing accessories

- Upper left hand front location

- Upper left hand rear location

- Upper right hand front location:

- Upper right hand rear location

- Lower left hand front location

- Front housing accessory drives

- Front power take-offs

- Crankshaft pulleys

- Damper guard removals

PROTECTION SYSTEM

- Air inlet shutoffs

- Switches and contactors

- Explosion relief valve

- Sensors

STARTING SYSTEM

- Starting motors or barring divice

- Air starting motors options

- Battery sets – 24 volt – Dry

- Battery rack

- Jacket Water Heater

GENERAL

- Tool set

- Caterpillar datalink wire

SVCE TOOLS/SHIP PROT/FACTORY SUPPORT

- Commissioning

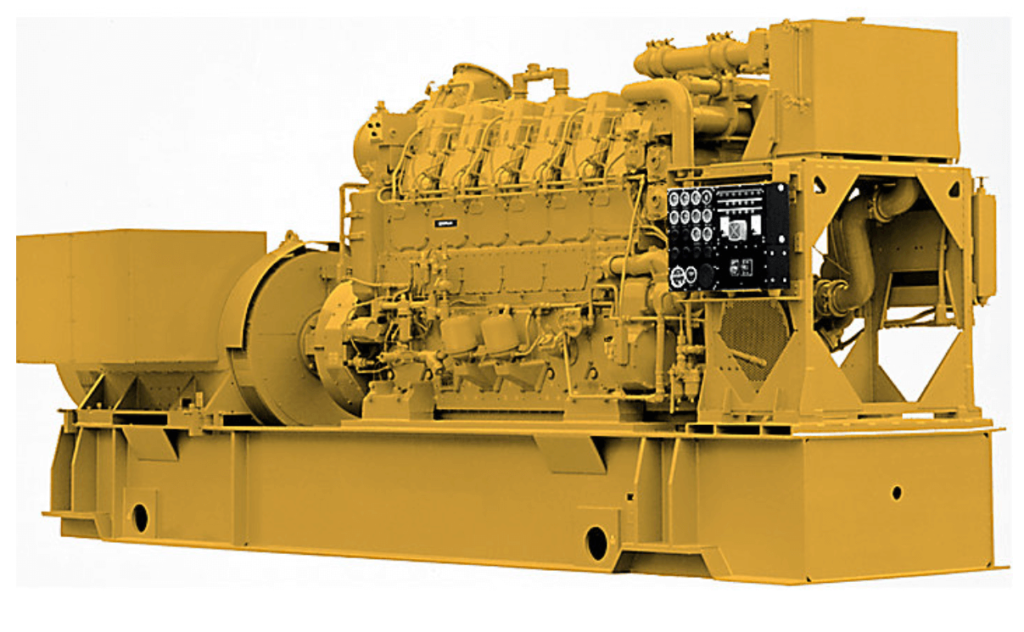

Caterpillar Engine 48 – Marine Generator Sets C280-6

KEY SPECS

Minimum Rating

1760 ekW (2200 kVA)

Maximum Rating

1820 ekW (2275 kVA)

Frequency

50 Hz or 60 Hz

Overview

Cat C280-6 Marine Generator Set

Key Features and Benefits

A3 Ecu:

Advantages

CAN J1939 data link Waterproof connectors, Maintenance-free, Backup ECU for redundant governing

Electronic Advantages

Load feedback, Programmable droop, Adjustable gain, Adjustable fuel/air ratio control, Histograms of engine operation, Cat Messenger display presents diagnostics and other engine parameters

Data Advantages Through J1939 Link

Engine speed, Boost pressure, Throttle position, Fuel consumption rate, Inlet manifold temperature, Diagnostic codes and events, Configuration, Desired engine speed, Battery voltage, Engine load, Lifetime totals — engine hours, fuel burned, idle fuel, idle hours, Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

- Customer Interface Panel:

Advantages

Interfaces with standard Cat® Marine Monitoring System (PLC in Price List), Provides visual indication of ECU functionality, Accepts 4 — 20 mA or PWM remote throttle speed input, Marine alarm and protection

- Electronic Unit Injectors

Advantages

“Drop-in” installation, No threaded fuel connections, High pressure inside injector only, Does not require double wall fuel lines or leak collection device, Injector synchronization not required

PRODUCT SPECIFICATIONS FOR C280-6

GENERATOR SET SPECIFICATIONS

Minimum Rating | 1760 ekW (2200 kVA) |

Maximum Rating | 1820 ekW (2275 kVA) |

Frequency | 50 Hz or 60 Hz |

Speed | 1000 rpm (50 hz) or 900 rpm (60 hz) |

Emissions/Fuel Strategy | EPA Tier 2, IMO II |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-Aftercooled |

Bore | 11 in |

Stroke | 11.8 in |

Displacement | 6773 in³ |

Governor Type | Electronic |

Fuel System | EUI |

Compression Ratio 50 Hz | 13.1 |

Compression Ratio 60 Hz | 13:1 |

Engine Model | In-line 6, 4-Stroke-Cycle Diesel |

GENERATOR SET DIMENSIONS

Length | 280.3 in |

Width | 77.2 in |

Height | 154.9 in |

Weight – Estimated | 18000 lb |

C280-6 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler — fresh water, corrosion resistant coated (air side); air inlet shutoff; breather — crankcase, top-mounted; turbocharger — engine oil lubricated

CONTROL SYSTEM

- Single Caterpillar® A3 electronic control unit (ECU) with electronic unit injector fuel system, rigid wiring harness (10 amp, 24 volt power required to drive ECUs)

COOLING SYSTEM

- Engine coolant water drains

EXHAUST SYSTEM

- Dry, gas tight, exhaust manifold

FUEL SYSTEM

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38° C), fuel transfer pump (mounted on left-hand side), duplex fuel filters, electronically controlled unit injectors

LUBE OIL SYSTEM

- Centrifugal oil filters with single shutoff, service side engine mounted on cylinder block inspection covers includes installed oil lines and single shutoff valve, filters centrifuge bypass oil from the main lubricating oil pump, can be serviced with the engine running, oil filler and dipstick valve, oil pressure regulating valves, crankcase explosion relief valves

GENERAL

- Caterpillar yellow paint; gear-driven pumps: fuel, oil, jacket water, aftercooler/oil cooler water; service literature

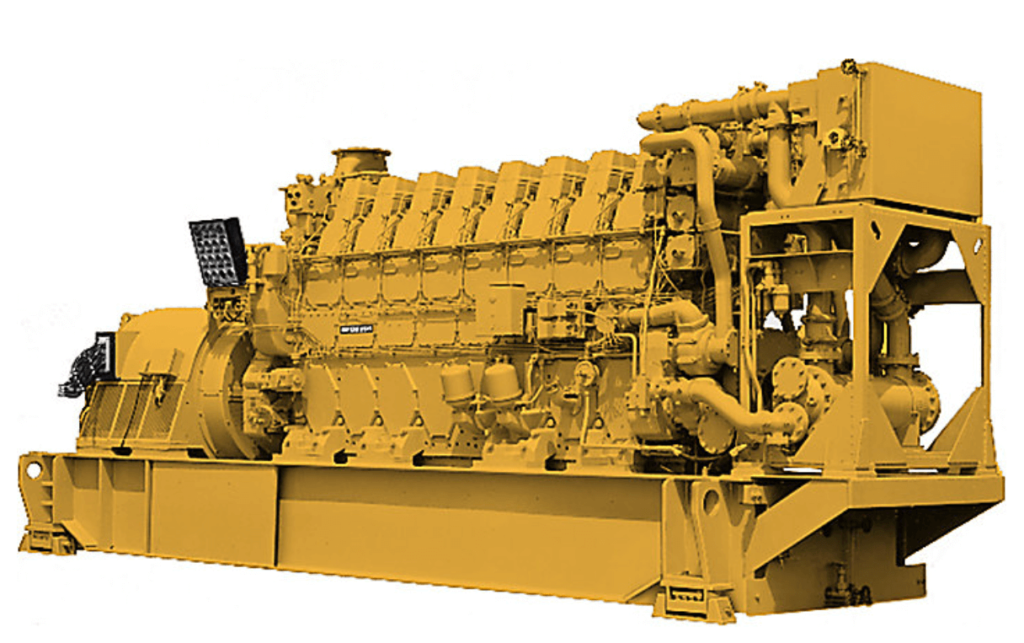

Caterpillar Engine 49 – Marine Generator Sets C280-8

KEY SPECS

Minimum Rating

2350 ekW (2938 kVA)

Maximum Rating

2420 ekW (3025 kVA)

Frequency

50 Hz or 60 Hz

Overview

Cat C280-8 Marine Generator Set

Key Features and Benefits

A3 Ecu

ADVANTAGES:

CAN J1939 data link Waterproof connectors, Maintenance-free, Backup ECU for redundant governing

ELECTRONIC ADVANTAGES:

Load feedback, Programmable droop, Adjustable gain, Adjustable fuel/air ratio control, Histograms of engine operation, Cat Messenger display presents diagnostics and other engine parameters

DATA ADVANTAGES THROUGH J1939 LINK:

Engine speed, Boost pressure, Throttle position, Fuel consumption rate, Inlet manifold temperature, Diagnostic codes and events, Configuration, Desired engine speed, Battery voltage, Engine load, Lifetime totals — engine hours, fuel burned, idle fuel, idle hours, Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

Customer Interface Panel

ADVANTAGES:

Interfaces with standard Cat® Marine Monitoring System (PLC in Price List), Provides visual indication of ECU functionality, Accepts 4 — 20 mA or PWM remote throttle speed input, Marine alarm and protection

Electronic Unit Injectors

ADVANTAGES:

“Drop-in” installation, No threaded fuel connections, High pressure inside injector only, Does not require double wall fuel lines or leak collection device, Injector synchronization not required

PRODUCT SPECIFICATIONS FOR C280-8

GENERATOR SET SPECIFICATIONS

Minimum Rating | 2350 ekW (2938 kVA) |

Maximum Rating | 2420 ekW (3025 kVA) |

Frequency | 50 Hz or 60 Hz |

Speed | 1000 rpm (50 hz) or 900 rpm (60 hz) |

Emissions/Fuel Strategy | EPA Tier 2, IMO II |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-Aftercooled |

Bore | 11 in |

Stroke | 11.8 in |

Displacement | 9031 in³ |

Governor Type | Electronic |

Fuel System | EUI |

Compression Ratio 50 Hz | 13.1 |

Compression Ratio 60 Hz | 13:1 |

Engine Model | In-line 8, 4-Stroke-Cycle Diesel |

GENERATOR SET DIMENSIONS

Length | 316.5 in |

Width | 77.2 in |

Height | 155 in |

Weight – Estimated | 25000 lb |

C280-8 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler — fresh water, corrosion resistant coated (air side); air inlet shutoff; breather — crankcase, top-mounted; turbocharger — engine oil lubricated

CONTROL SYSTEM

- Single Caterpillar® A3 electronic control unit (ECU) with electronic unit injector fuel system, rigid wiring harness (10 amp, 24 volt power required to drive ECUs)

COOLING SYSTEM

- Engine coolant water drains

EXHAUST SYSTEM

- Dry, gas tight, exhaust manifold

FUEL SYSTEM

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38° C), fuel transfer pump (mounted on left-hand side), duplex fuel filters, electronically controlled unit injectors

LUBE OIL SYSTEM

- Centrifugal oil filters with single shutoff, service side engine mounted on cylinder block inspection covers includes installed oil lines and single shutoff valve, filters centrifuge bypass oil from the main lubricating oil pump, can be serviced with the engine running, oil filler and dipstick valve, oil pressure regulating valves, crankcase explosion relief valves

GENERAL

- Caterpillar yellow paint; gear-driven pumps: fuel, oil, jacket water, aftercooler/oil cooler water; service literature

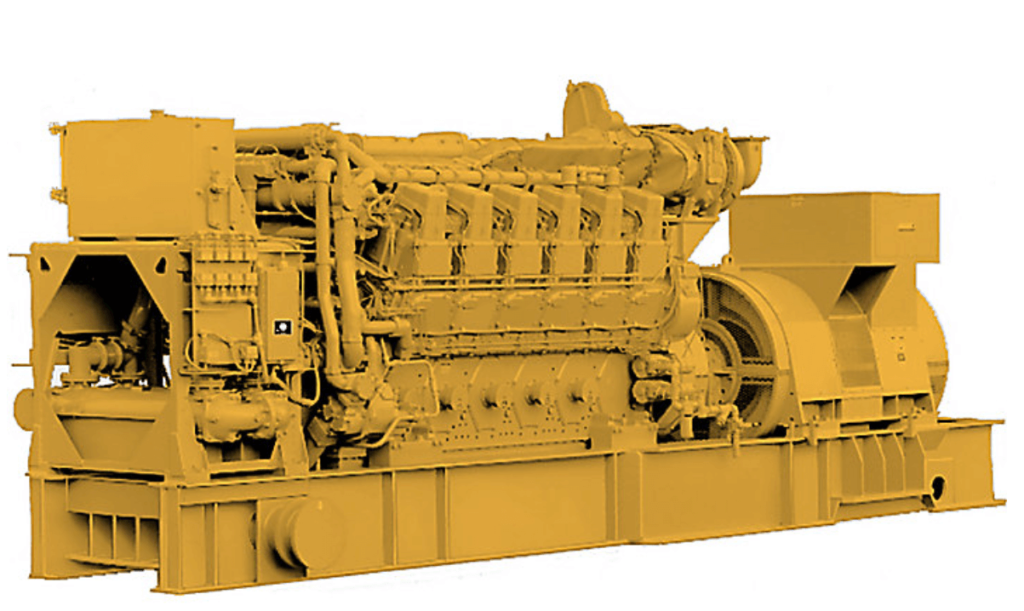

Caterpillar Engine 50 – Marine Generator Sets C280-12

KEY SPECS

Minimum Rating

3520 ekW (4400 kVA)

Maximum Rating

3640 ekW (4550 kVA)

Frequency

50 Hz or 60 Hz

Overview

Cat C280-12 Marine Generator Set

Key Features and Benefits

- A3 Ecu – Advantages: CAN J1939 data link Waterproof connectors, Maintenance-free, Backup ECU for redundant governing

- A3 Ecu – Electronic Advantages: Load feedback, Programmable droop, Adjustable gain, Adjustable fuel/air ratio control, Histograms of engine operation, Cat Messenger display presents diagnostics and other engine parameters

- A3 Ecu – Data Advantages Through J1939 Link: Engine speed, Boost pressure, Throttle position, Fuel consumption rate, Inlet manifold temperature, Diagnostic codes and events, Configuration, Desired engine speed, Battery voltage, Engine load, Lifetime totals — engine hours, fuel burned, idle fuel, idle hours, Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

- Customer Interface Panel: Interfaces with standard Cat® Marine Monitoring System (PLC in Price List), Provides visual indication of ECU functionality, Accepts 4 — 20 mA or PWM remote throttle speed input, Marine alarm and protection

- Electronic Unit Injectors: “Drop-in” installation, No threaded fuel connections, High pressure inside injector only, Does not require double wall fuel lines or leak collection device, Injector synchronization not required

PRODUCT SPECIFICATIONS FOR C280-12

GENERATOR SET SPECIFICATIONS

Minimum Rating | 3520 ekW (4400 kVA) |

Maximum Rating | 3640 ekW (4550 kVA) |

Frequency | 50 Hz or 60 Hz |

Speed | 1000 rpm (50 hz) or 900 rpm (60 hz) |

Emissions/Fuel Strategy | EPA Tier 2, IMO II |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-Aftercooled |

Bore | 11 in |

Stroke | 11.8 in |

Displacement | 13546 in³ |

Governor Type | Electronic |

Fuel System | EUI |

Compression Ratio 50 Hz | 13.1 |

Compression Ratio 60 Hz | 13:1 |

Engine Model | Vee 12, 4-Stroke-Cycle Diesel |

GENERATOR SET DIMENSIONS

Length | 316.5 in |

Width | 77.2 in |

Height | 155 in |

Weight – Estimated | 25000 lb |

C280-12 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler — fresh water, corrosion resistant coated (air side); air inlet shutoff; breather — crankcase, top-mounted; turbocharger — engine oil lubricated

CONTROL SYSTEM

- Single Caterpillar® A3 electronic control unit (ECU) with electronic unit injector fuel system, rigid wiring harness (10 amp, 24 volt power required to drive ECUs)

COOLING SYSTEM

- Engine coolant water drains

EXHAUST SYSTEM

- Dry, gas tight, exhaust manifold

FUEL SYSTEM

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38° C), fuel transfer pump (mounted on left-hand side), duplex fuel filters, electronically controlled unit injectors

LUBE OIL SYSTEM

- Centrifugal oil filters with single shutoff, service side engine mounted on cylinder block inspection covers includes installed oil lines and single shutoff valve, filters centrifuge bypass oil from the main lubricating oil pump, can be serviced with the engine running, oil filler and dipstick valve, oil pressure regulating valves, crankcase explosion relief valves

GENERAL

- Caterpillar yellow paint; gear-driven pumps: fuel, oil, jacket water, aftercooler/oil cooler water; service literature

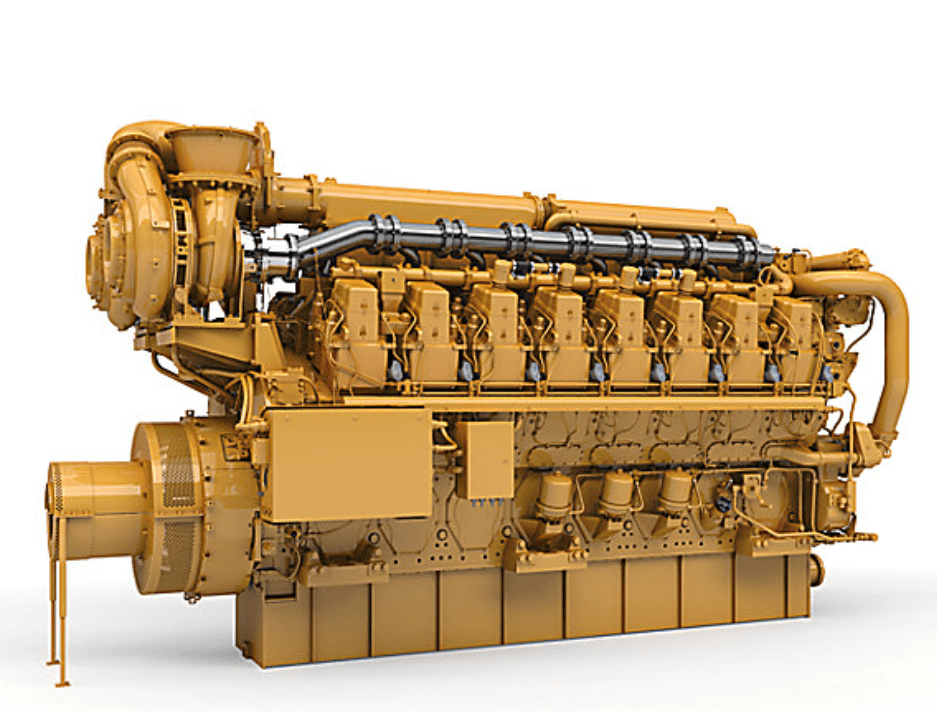

Caterpillar Engine 51 – Marine Generator Sets C280-16

KEY SPECS

Minimum Rating

4700 ekW (5875 kVA)

Maximum Rating

4840 ekW (6050 kVA)

Frequency

50 Hz or 60 Hz

Overview

Cat C280-16 Marine Generator Set

Key Features and Benefits

- A3 Ecu – Advantages: CAN J1939 data link Waterproof connectors, Maintenance-free, Backup ECU for redundant governing

- A3 Ecu – Electronic Advantages: Load feedback, Programmable droop, Adjustable gain, Adjustable fuel/air ratio control, Histograms of engine operation, Cat Messenger display presents diagnostics and other engine parameters

- A3 Ecu – Data Advantages Through J1939 Link: Engine speed, Boost pressure, Throttle position, Fuel consumption rate, Inlet manifold temperature, Diagnostic codes and events, Configuration, Desired engine speed, Battery voltage, Engine load, Lifetime totals — engine hours, fuel burned, idle fuel, idle hours, Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

- Customer Interface Panel – Advantages: Interfaces with standard Cat® Marine Monitoring System (PLC in Price List) Provides visual indication of ECU functionality, Accepts 4 — 20 mA or PWM remote throttle speed input, Marine alarm and protection

- Electronic Unit Injectors – Advantages: “Drop-in” installation, No threaded fuel connections, High pressure inside injector only, Does not require double wall fuel lines or leak collection device, Injector synchronization not required

PRODUCT SPECIFICATIONS FOR C280-16

GENERATOR SET SPECIFICATIONS

Minimum Rating | 4700 ekW (5875 kVA) |

Maximum Rating | 4840 ekW (6050 kVA) |

Frequency | 50 Hz or 60 Hz |

Speed | 1000 rpm (50 hz) or 900 rpm (60 hz) |

Emissions/Fuel Strategy | EPA Tier 2, IMO II |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-Aftercooled |

Bore | 11 in |

Stroke | 11.8 in |

Displacement | 18062 in³ |

Governor Type | Electronic |

Fuel System | EUI |

Compression Ratio 50 Hz | 13.1 |

Compression Ratio 60 Hz | 13:1 |

Engine Model | Vee 16, 4-Stroke-Cycle Diesel |

GENERATOR SET DIMENSIONS

Length | 366.7 in |

Width | 78.3 in |

Height | 164.1 in |

Weight | 31000 kg/ 68343 lb (engine dry weight), 18145 kg/ 40000 lb (generator weight) |

C280-16 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Aftercooler — fresh water, corrosion resistant coated (air side); air inlet shutoff; breather — crankcase, top-mounted; turbocharger — engine oil lubricated

CONTROL SYSTEM

- Single Caterpillar® A3 electronic control unit (ECU) with electronic unit injector fuel system, rigid wiring harness (10 amp, 24 volt power required to drive ECUs)

COOLING SYSTEM

- Engine coolant water drains

EXHAUST SYSTEM

- Dry, gas tight, exhaust manifold

FUEL SYSTEM

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38° C), fuel transfer pump (mounted on left-hand side), duplex fuel filters, electronically controlled unit injectors

LUBE OIL SYSTEM

- Centrifugal oil filters with single shutoff, service side engine mounted on cylinder block inspection covers includes installed oil lines and single shutoff valve, filters centrifuge bypass oil from the main lubricating oil pump, can be serviced with the engine running, oil filler and dipstick valve, oil pressure regulating valves, crankcase explosion relief valves

GENERAL

- Caterpillar yellow paint; gear-driven pumps: fuel, oil, jacket water, aftercooler/oil cooler water; service literature