Brand & Engine

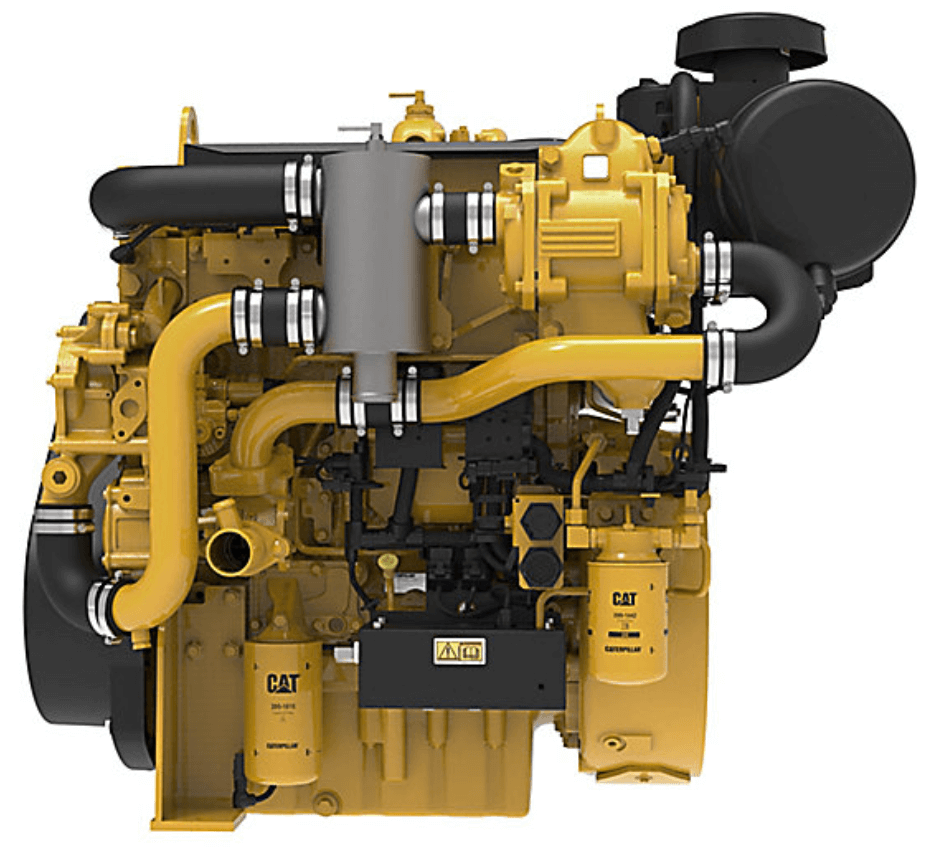

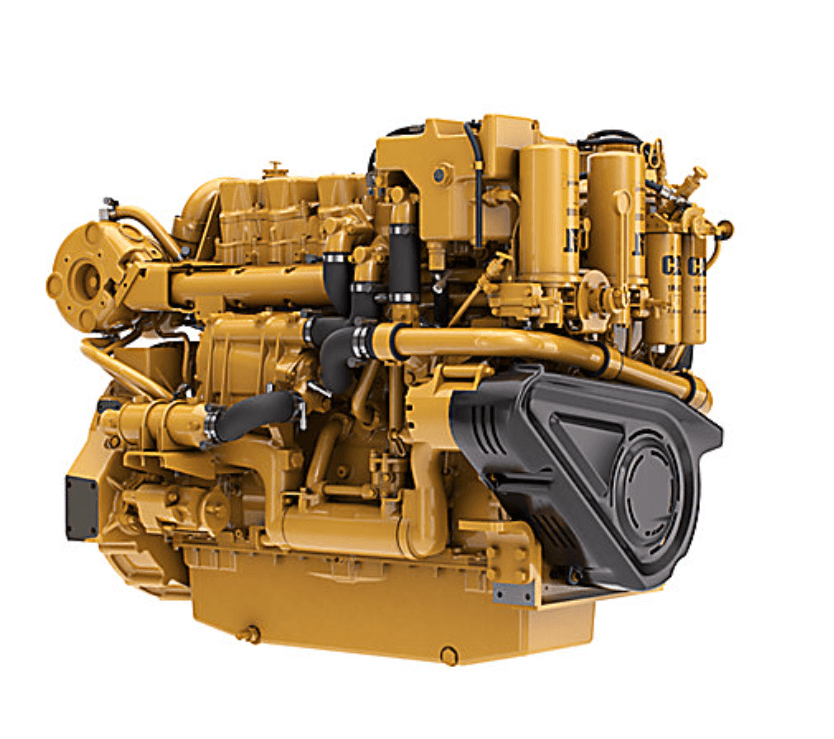

Caterpillar Engine 52 – Auxiliary Engines C4.4 (ELECTRONIC)

KEY SPECS

Power Range

71/81/108/129 bkW @ 1800 rpm, 71/86/108 bkW @ 1500 rpm

Length

33.7 in

Height

40.9 in

Overview

C4.4 (Electronic Control System)

Key Features and Benefits

- Simplicity = Reliability

- Configure the engine how you want it, package it yourself

- Compact engine profile with high power density

- Ease of repower with multiple cooling system options: Single circuit keel cooling /Separate circuit keel cooling / Heat exchanger

- Clean, smooth, and quiet operations

- Advanced fuel system provides excellent fuel consumption and low smoke

- Proven core engine design with millions of operating hours

- Fewer maintenance touchpoints and longer service intervals

- Global dealer network for unparalleled support

PRODUCT SPECIFICATIONS FOR C4.4 (ELECTRONIC)

POWER RATING

Power Range | 71/81/108/129 bkW @ 1800 rpm, 71/86/108 bkW @ 1500 rpm |

DIMENSIONS & WEIGHTS

Length | 33.7 in |

Height | 40.9 in |

Minimum Width | 30.6 in |

Maximum Width | 32 in |

Minimum Engine Dry Weight | 1200 lb |

Maximum Engine Dry Weight | 1278 lb |

ENGINE SPECIFICATIONS

Configuration | In-line 4, 4-stroke-cycle diesel |

Emissions | U.S. EPA Tier 3 certified, EU Stage V certified |

Rated Engine Speed | 1500/1800 rpm |

Bore | 4.13 in |

Stroke | 5 in |

Displacement | 268 in³ |

Aspiration | Turbocharged-aftercooled and turbo only aspiration (Turbocharged aspiration only for 65ekW (71bkW)) |

Governor | Electronic (A5 ECM) |

Refill Capacity | Lube Oil System w/Oil filter change: 11 L 2.8 gal) |

Oil Change Interval | 500 hrs |

Cooling | Heat exchanger, combined circuit keel cooling, or separate circuit keel cooling |

Flywheel Housing | SAE No. 03 with SAE 11.5 flywheel (126 teeth) |

C4.4 (ELECTRONIC) STANDARD EQUIPMENT

COOLING SYSTEM

- Gear-driven jacket-water and auxiliary water pumps

- Engine mounted air cleaner and expansion tank

- Integral plate-type oil cooler

EXHAUST SYSTEM

- Watercooled exhaust manifold and turbocharger

FUEL SYSTEM

- Common Rail fuel system

- Electric fuel priming pump

GENERAL

- Internal engine balancing shaft

- Self-tensioning multi-vee belt drive

LUBE SYSTEM

- Open crankcase ventilation system

MOUNTING SYSTEM

- Engine mounted fuel and oil filter

- Engine mounted customer interface and control relays

STARTING SYSTEM

- 12V or 24V starter motor

C4.4 (ELECTRONIC) OPTIONAL EQUIPMENT

GENERAL

- MGGP 200 Gauge Panel and interface harness

- Engine shutdown sensors and shutdown controller

- Double wall high pressure fuel lines

- EMCP engine control panel

- Exhaust elbow and bellows

- Rear mounting feet

- Glow plugs

- Jacket water heater

- Jacket water connections (keel cooled)

- S•O•SSM sample points

- Glow plugs

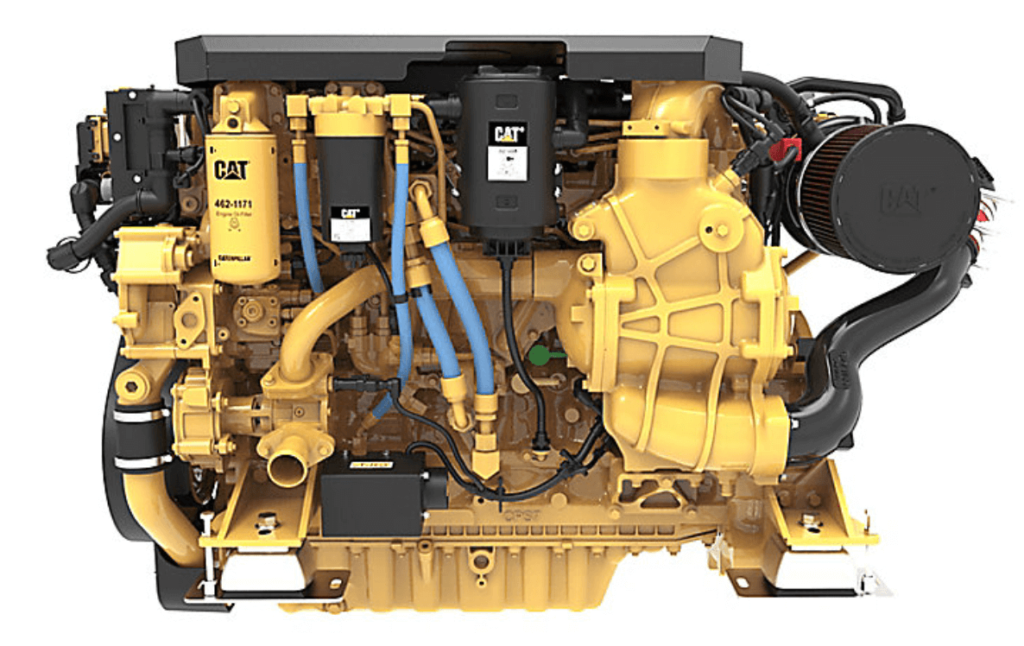

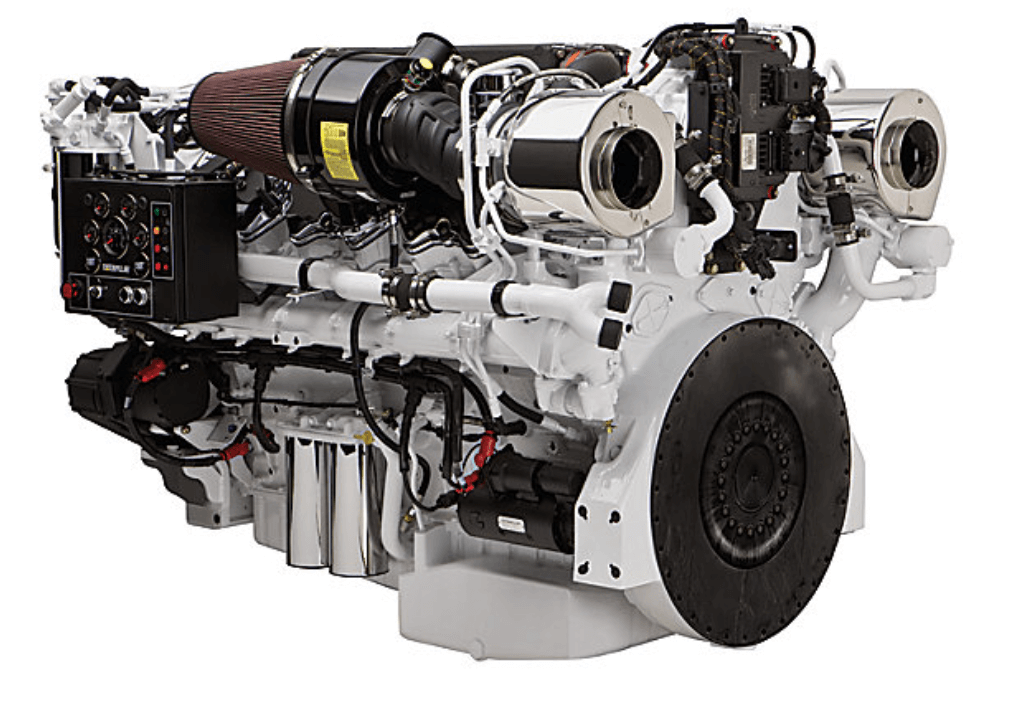

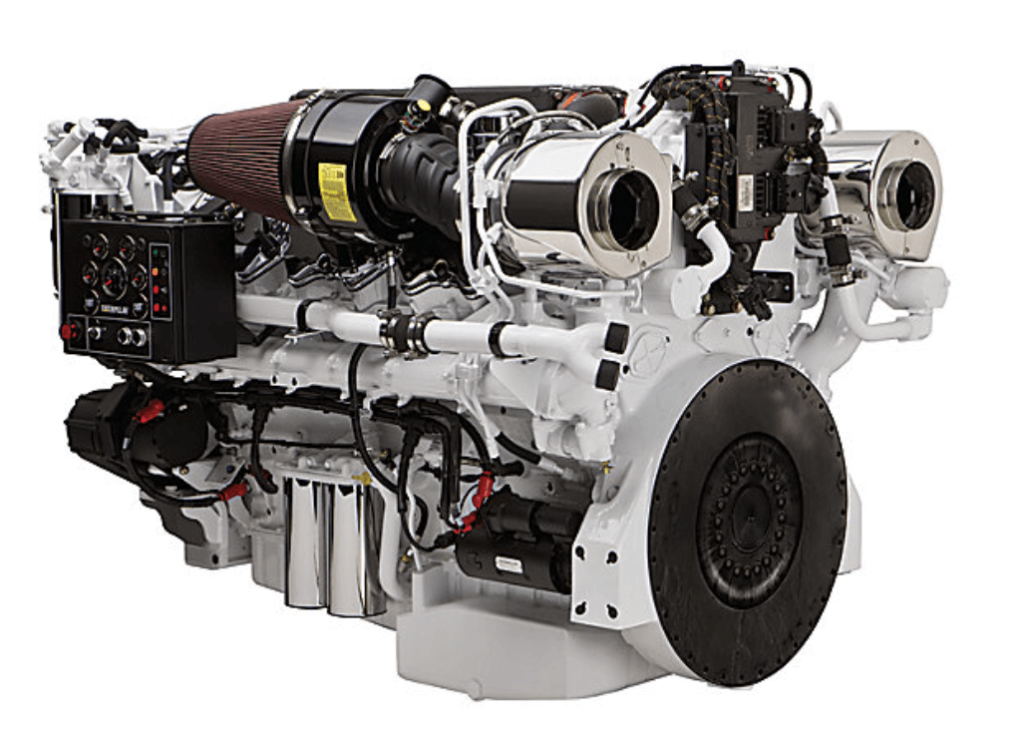

Caterpillar Engine 53 – Auxiliary Engines C7.1 TIER 3 / IMO II

KEY SPECS

Length

43.1 in

Power Range

208 bkW (280 bhp) @ 2300 rpm

Height

35.1 in

Overview

C7.1 Marine Auxiliary Engine (U.S. EPA Tier 3 / IMO II)

Key Features and Benefits

- Reliability & Durability: Superior response time and acceleration; 12V or 24V electrical system; Gear driven jacket water pump and sea water pump for superior reliability; Maintenance free valve train with hydraulic valve lash adjusters

- Easy to Use: Compatible with Cat® displays and electronics; Self priming fuel system ensures a smooth start every time

- Environment Friendly: No visible smoke; Common rail fuel system enables optimum combustion and low emissions; Reduced combustion noise through advanced electronic control; Closed crankcase ventilation system improves engine room cleanliness

PRODUCT SPECIFICATIONS FOR C7.1 TIER 3 / IMO II

DIMENSIONS & WEIGHTS

Length | 43.1 in |

Height | 35.1 in |

Minimum Width | 31.4 in |

Maximum Width | 33.5 in |

Minimum Engine Dry Weight | 1609 lb |

Maximum Engine Dry Weight | 1676 lb |

POWER RATING

Power Range | 208 bkW (280 bhp) @ 2300 rpm |

ENGINE SPECIFICATIONS

Configuration | In-line 6, 4-stroke-cycle diesel |

Emissions | U.S. EPA Tier 3 / IMO II emissions certified (commercial), RCD 2016 compliant, EU Stage IIIA compliant, CCNR Stage II through reciprocity with EU Stage IIIA |

Rated Engine Speed | 2300 rpm |

Bore | 4.13 in |

Stroke | 5.31 in |

Displacement | 428 in³ |

Aspiration | Turbocharged-aftercooled aspiration |

Governor | Electronic (A5E2 V2 ECM) |

Refill Capacity | Lube Oil System w/Oil filter change: 20 L (5.3 gal) |

Oil Change Interval | 500 hrs |

Cooling | Heat exchanger or keel cooled |

Flywheel Housing | SAE No. 03 with SAE 11.5 in flywheel |

Rotation | Counterclockwise from flywheel end |

C7.1 TIER 3 / IMO II STANDARD EQUIPMENT

COOLING SYSTEM

- Gear driven jacket water pump

- Corrosion resistant sea water aftercooler

- Fuel cooler

EXHAUST SYSTEM

- Watercooled turbocharger and exhaust manifold

FUEL SYSTEM

- Common rail fuel system

- Electric fuel priming pump

GENERAL

- Vibration damper and guard

- Self-tensioning multi-vee belt drive

LUBE SYSTEM

- Closed crankcase ventilation system

- Integral engine oil cooler

MOUNTING SYSTEM

- Front and rear engine mounting brackets

STARTING SYSTEM

- Starter motors – 12V or 24V

C7.1 TIER 3 / IMO II OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Various 6″ water cooled exhaust elbow configurations

COOLING SYSTEM

- Engine mounted bilge pumps and auxiliary water pumps with electromagnetic clutch

- Tube and bundle jacket water heat exchanger and gear-driven sea water pump (rubber impeller)

- Jacket water heater

- Cabin heater (calorifier) connections

FUEL SYSTEM

- SOLAS double wall high pressure fuel lines kit

LUBE SYSTEM

- Left-hand and right-hand oil dipsticks

- Transmission gear oil cooler (engine mounted)

PROTECTION SYSTEM

- Additional engine and transmission sensor packages for on or off vessel monitoring

STARTING SYSTEM

- Engine mounted secondary alternator – 24V 100 amp or 12V 175 amp

- Glow plugs

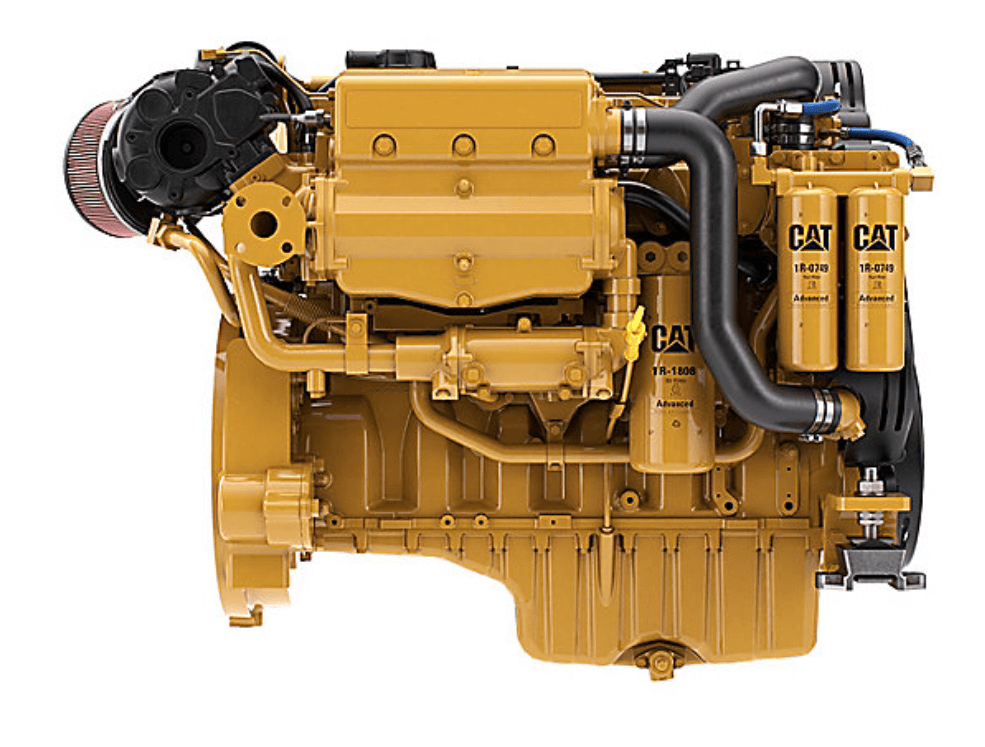

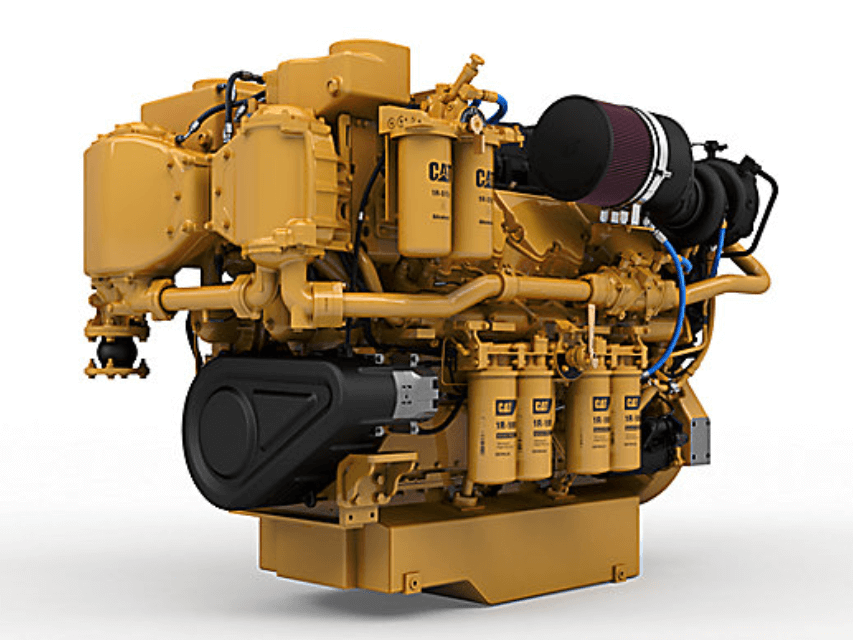

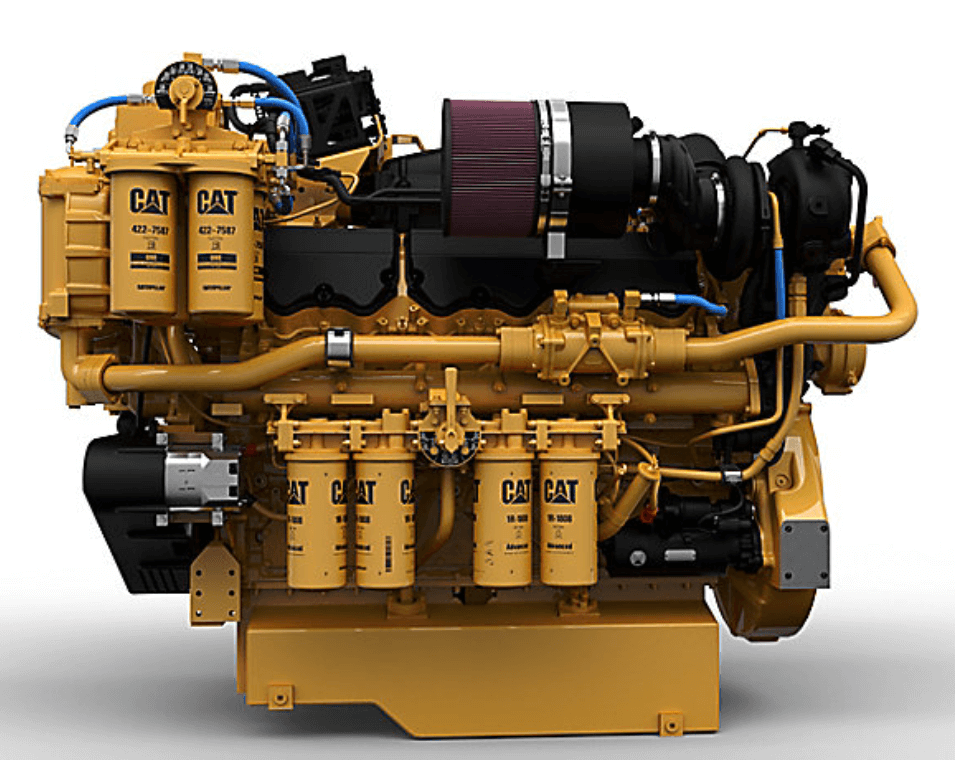

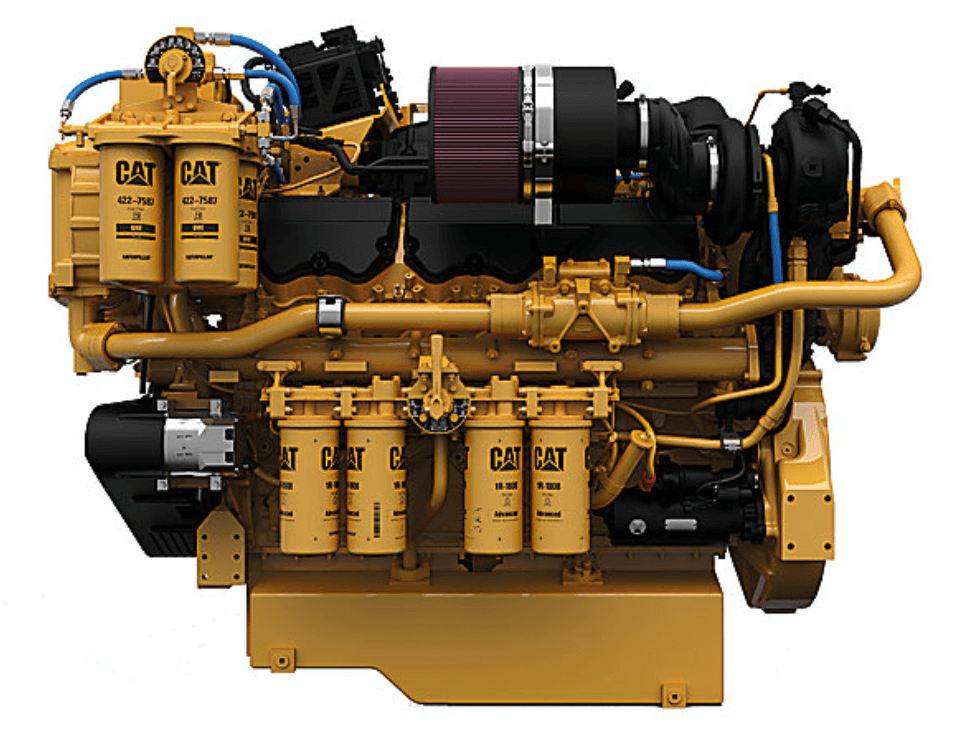

Caterpillar Engine 54 – Auxiliary Engines C9.3 AUXILIARY ENGINE

KEY SPECS

Power Range

292 bhp – 436 bhp (218 bkW – 325 bkW)

Rated Engine Speed

1,500, 1,800 rpm

Emissions

IMO II, IMO III, U.S. EPA Tier 3, China Stage II

Overview

C9.3 Marine Auxiliary Engine

Key Features & Benefits

- Electronic control system provides industry-leading torque and throttle response at low speeds, while maintaining fuel efficiency at high speeds

- Common rail fuel system enables optimum combustion and low emissions

- RH and LH locations service options for fuel and oil filters, as well as dipstick location for easily accessible service

- Compatible with Cat® displays

- Available remote-mounted display panel with start, stop, and engine diagnostics

- 12V or 24V electrical system

- Certified by all marine classification societies

- Utilizes SCR technology enabling IMO III emissions compliance while lowering operational costs

PRODUCT SPECIFICATIONS FOR C9.3 AUXILIARY ENGINE

POWER RATING

Power Range | 292 bhp – 436 bhp (218 bkW – 325 bkW) |

ENGINE SPECIFICATIONS

Rated Engine Speed | 1,500, 1,800 rpm |

Emissions | IMO II, IMO III, U.S. EPA Tier 3, China Stage II |

Aspiration | Turbocharged-aftercooled |

Stroke | 5.8 in |

Bore | 4.5 in |

Displacement | 567.5 in³ |

Rotation from Flywheel End | Counterclockwise |

Configuration | In-Line 6, 4-Stroke-Cycle Diesel |

Cooling | Heat exchanger and separate or combined keel cooled options |

Oil Change Interval | 500 hrs |

Governor | Electronic |

Flywheel Housing | SAE No. 1 (113 teeth) |

Refill Capacity | Lube Oil System w/oil filter change: 24.5 L (6.5 gal) |

DIMENSIONS & WEIGHTS

Width – Engine | 38.5 in |

Height | 43 in |

Length – Engine | 57.2 in |

Engine Dry Weight – Approximate | 2083-2474 lbs (945-1122 kg) |

C9.3 AUXILIARY ENGINE STANDARD EQUIPMENT

STANDARD EQUIPMENT

- Vibration damper and guard

- Engine oil cooler

- Thermostats and housing

- Gear-driven sea water pump (self-priming)

- Electronic control system

- Water-cooled turbocharger and exhaust manifold

- Primary fuel filters

- Common rail fuel system

- Corrosion-resistant Sea water aftercooler

- Shell and tube jacket water heat exchanger

C9.3 AUXILIARY ENGINE OPTIONAL EQUIPMENT

OPTIONAL ATTACHMENTS

- Electric fuel priming pump

- Fuel cooler

- Transmission gear oil cooler (engine mounted for HEX)

- Additional engine and transmission sensor packages

- Alternators – 24V 70 or 105 amp, 12V 110 amp

- Electric starting motors – 12V or 24V

- Instrument panels

- PTO Drives – V-belt pulley stack, stub shaft

- Double wall fuel rail

- Duplex fuel and oil filters

- Air starting motor

- Closed crankcase ventilation

- Dual electric starting motors or combined electric/air

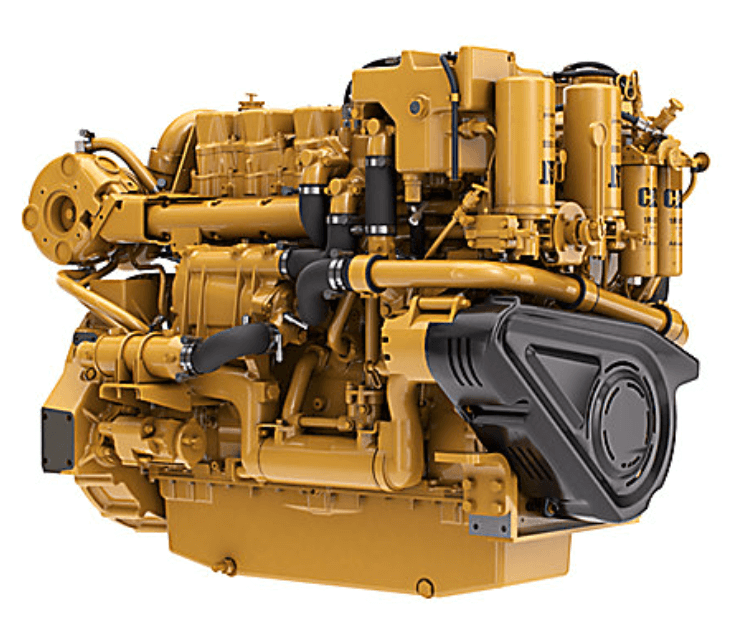

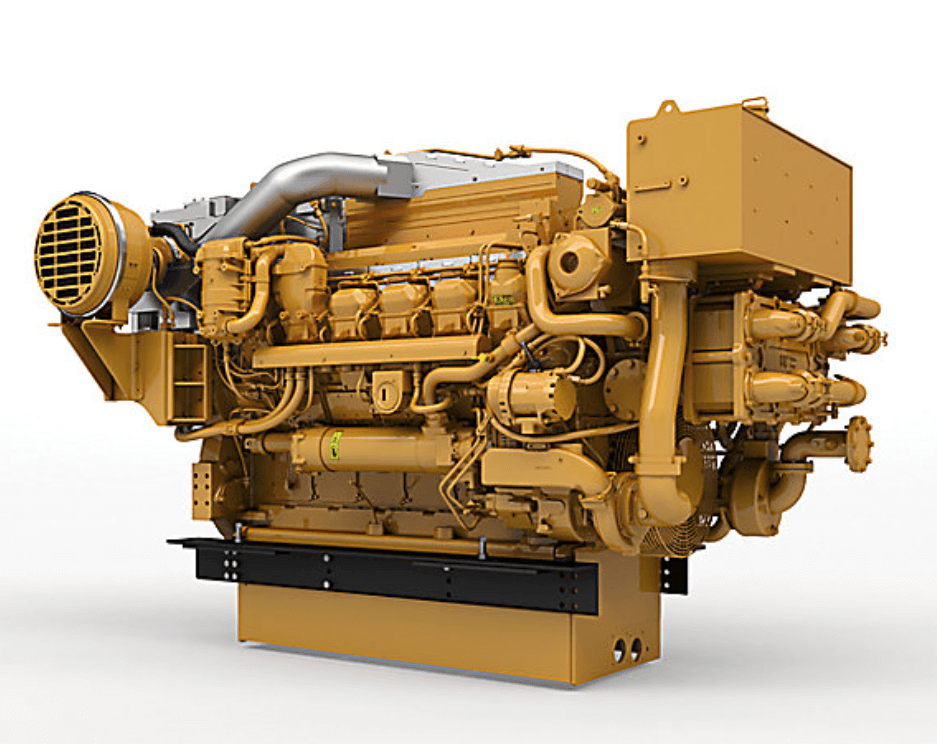

Caterpillar Engine 55 – Auxiliary Engines C18 IMO II

KEY SPECS

Minimum Rating

404 BHP

Maximum Rating

660 BHP

Aspiration

TA, TTA

Overview

C18 auxiliary/generator set engines incorporate a separate circuit aftercooling system (SCAC) for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines also contribute to minimizing owning and operating costs. The IMO II compliant ratings are available with heat exchanger or keel cooled options. All major MCS type approvals are available from the factory.

Key Features and Benefits

- Separate Circuit Aftercooling System: The primary advantage of the separate circuit aftercooling system (SCAC) is that no sea water circulates through the aftercooler

- Emissions: IMO II and EU IWW compliant

- Cooling System: Heat exchanger and Keel cooled options for all ratings

- Turbo Configurations: Single turbo configurations for all ratings

- Competitive Size and Weight:

- Marine Certifications: All major MCS type approvals available from factory

PRODUCT SPECIFICATIONS FOR C18 IMO II

POWER RATING

Minimum Rating | 404 BHP |

Maximum Rating | 660 BHP |

ENGINE SPECIFICATIONS

Aspiration | TA, TTA |

Rotation from Flywheel End | Counterclockwise |

Bore | 5.7 in |

Displacement | 1106 in³ |

Configuration | In-Line 6, 4-Stroke-Cycle Diesel |

Stroke | 7.2 in |

DIMENSIONS & WEIGHTS

Height | 51.2 in |

Length | 73 in |

Width | 44.6 in |

Dry Weight | 1950 lb |

C18 IMO II STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Open Crankcase Ventilation (OCV) system

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- Programmable low idle

- Electronic diagnostics and fault logging

- Electronic fuel/air ratio control

- Engine Protection Mode for extended ambient conditions – EPA Tier 3 Ratings Only

- 70-pin customer connector

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Engine JW and SCAC Shell & Tube Heat Exchangers for HEX cooled engines

- SCAC pump, gear driven, for HEX cooled engines only

- Jacket water pump, gear driven

- Auxiliary water pump, gear driven

- Sea water pump, bronze impeller, gear driven

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- 152 mm (6 in) round flanged outlet

- Water-cooled exhaust manifold & turbocharger

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

FUEL SYSTEM

- Front service simplex fuel system

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Front service simplex oil system

- Center sump oil pan:

- Front and top service oil filler locations

- Front service dipstick

- Oil pump, gear driven

MOUNTING SYSTEM

- Front support – adjustable

POWER TAKE-OFFS

- Hydraulic Pump Drive

- Crankshaft Pulleys

- Front Stub Shaft

- Front Enclosed Clutch

GENERAL

- Front damper guard

- Front service engine

- Common electrical bonding point

- Engine does not ship with zinc components

- NOTE: These engines are for constant speed generator set applications only, and NOT to be used for variable speed applications

C18 IMO II OPTIONAL EQUIPMENT

EXHAUST SYSTEM

- Dry Elbows

- Water-Cooled Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

AIR INLET SYSTEM

- Air Inlet Adapter

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- Alternator Mounting Group

- Ammeter

CONTROL SYSTEM

- MECP I – Marine Engine Control Panel

- Caterpillar Alarm and Protection

- Load Sharing Attachment

COOLING SYSTEM

- Aux Expansion Tank Flange Kit

FUEL SYSTEM

- Duplex Fuel Filters

- Fuel Cooler

- Primary Fuel Filters

- Flexible Fuel Lines

INSTRUMENTATION

- Instrument Panels

- OEM Wiring Harness

- Gauges

- Oil Level Sensor

LUBE SYSTEM

- Duplex Oil Filters

- Sump Pump

POWER TAKE-OFFS

- Crankshaft Pulleys

- Front Stub Shaft

- Hydraulic Pump Drive Adapter

- Front Enclosed Clutch

PROTECTION SYSTEM

- Marine Classification Society and SOLAS

STARTING SYSTEM

- Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

MOUNTING SYSTEM

- Front Support

- REAR ENGINE SUPPORT

PACKING

- Engine Protective Cover

- Storage Preservation

- Export Packing

Caterpillar Engine 56 – Auxiliary Engines C18 TIER 3

KEY SPECS

Minimum Rating

624 BHP

Maximum Rating

803 BHP

Aspiration

TA, TTA

Overview

C18 ACERT auxiliary/generator set engines incorporate a separate circuit aftercooling system (SCAC) for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines also contribute to minimizing owning and operating costs. The EPA Tier 3, IMO II, EU Stage IIIA compliant ratings are available with heat exchanger or keel cooled options. All major MCS type approvals are available from the factory.

Key Features and Benefits

- Separate Circuit Aftercooling System: The primary advantage of the separate circuit aftercooling system (SCAC) is that no sea water circulates through the aftercooler

- Emissions: EPA Tier 3 compliant, IMO II and EU IWW compliant

- Cooling System: Heat exchanger and Keel cooled options for all ratings

- Turbo Configurations: Single turbo configurations for all ratings

- Competitive Size and Weight:

- Marine Certifications: All major MCS type approvals available from factory

PRODUCT SPECIFICATIONS FOR C18 TIER 3

POWER RATING

Minimum Rating | 624 BHP |

Maximum Rating | 803 BHP |

ENGINE SPECIFICATIONS

Aspiration | TA, TTA |

Bore | 5.7 in |

Displacement | 1106 in³ |

Configuration | In-Line 6, 4-Stroke-Cycle Diesel |

Stroke | 7.2 in |

Rotation from Flywheel End | Counterclockwise |

DIMENSIONS & WEIGHTS

Length | 73 in |

Height | 51.2 in |

Dry Weight | 1950 lb |

Width | 44.6 in |

C18 TIER 3 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Open Crankcase Ventilation (OCV) system

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- Programmable low idle

- Electronic diagnostics and fault logging

- Electronic fuel/air ratio control

- Engine Protection Mode for extended ambient conditions – EPA Tier 3 Ratings Only

- 70-pin customer connector

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Engine JW and SCAC Shell & Tube Heat Exchangers for HEX cooled engines

- SCAC pump, gear driven, for HEX cooled engines only

- Jacket water pump, gear driven

- Auxiliary water pump, gear driven

- Sea water pump, bronze impeller, gear driven

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- 152 mm (6 in) round flanged outlet

- Water-cooled exhaust manifold & turbocharger

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

FUEL SYSTEM

- Front service simplex fuel system

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Front service simplex oil system

- Center sump oil pan:

- Front and top service oil filler locations

- Front service dipstick

- Oil pump, gear driven

MOUNTING SYSTEM

- Front support – adjustable

POWER TAKE-OFFS

- Hydraulic Pump Drive

- Crankshaft Pulleys

- Front Stub Shaft

- Front Enclosed Clutch

GENERAL

- Front damper guard

- Front service engine

- Common electrical bonding point

- Engine does not ship with zinc components

- NOTE: These engines are for constant speed generator set applications only, and NOT to be used for variable speed applications

C18 TIER 3 OPTIONAL EQUIPMENT

EXHAUST SYSTEM

- Dry Elbows

- Water-Cooled Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

AIR INLET SYSTEM

- Air Inlet Adapter

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- Alternator Mounting Group

- Ammeter

CONTROL SYSTEM

- MECP I – Marine Engine Control Panel

- Caterpillar Alarm and Protection

- Load Sharing Attachment

COOLING SYSTEM

- Aux Expansion Flange Kit

FUEL SYSTEM

- Duplex Fuel Filters

- Fuel Cooler

- Primary Fuel Filters

- Flexible Fuel Lines

INSTRUMENTATION

- Instrument Panels

- OEM Wiring Harness

- Gauges

- Oil Level Sensor

LUBE SYSTEM

- Duplex Oil Filters

- Sump Pump

POWER TAKE-OFFS

- Crankshaft Pulleys

- Front Stub Shaft

- Hydraulic Pump Drive Adapter

- Front Enclosed Clutch

PROTECTION SYSTEM

- Marine Classification Society and SOLAS

STARTING SYSTEM

- Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

MOUNTING SYSTEM

- Front Support

- REAR ENGINE SUPPORT

PACKING

- Engine Protective Cover

- Storage Preservation

- Export Packing

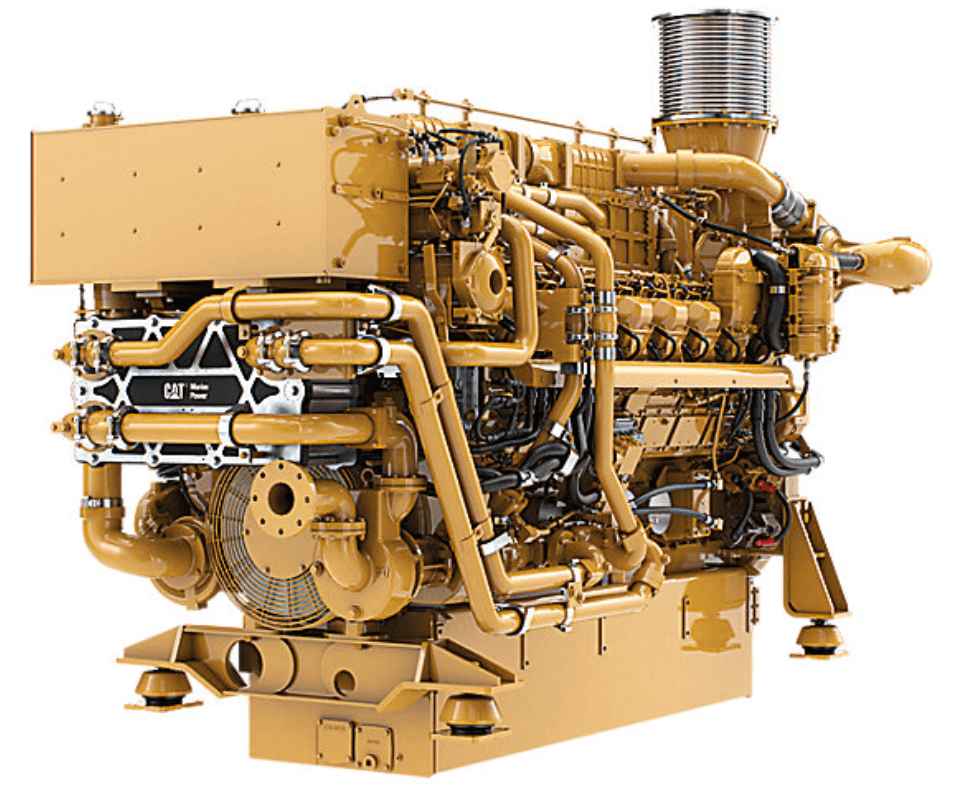

Caterpillar Engine 57 – Auxiliary Engines C32 IMO II

KEY SPECS

Minimum Rating

791 BHP

Maximum Rating

1333 BHP

Aspiration

TTA

Overview

C32 ACERT auxiliary/generator set engines incorporate a separate circuit aftercooling system (SCAC) for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines also contribute to minimizing owning and operating costs. The IMO II compliant ratings are available with heat exchanger or keel cooled options. Heat exchanger configurations have an optional front mounted sea water pump.

Key Features and Benefits

- Emissions: IMO II compliant for all ratings

- Worldwide Support: Extensive service network of dealers; Unparalleled service from authorized marine dealers

- Durability: Proven engine operating history; Performance iron with thousands of hours of validation testing for quality and durability

- Reliability: 60 months standard warranty

- Cooling System: Heat Exchanger or Keel Cooling; Heat exchanger configurations: optional front mounted sea water pump

- Aftercooling System: Separate circuit aftercooling system (SCAC): no seawater circulating through the aftercooler

PRODUCT SPECIFICATIONS FOR C32 IMO II

POWER RATING

Minimum Rating | 791 BHP |

Maximum Rating | 1333 BHP |

ENGINE SPECIFICATIONS

Aspiration | TTA |

Displacement | 1959 in³ |

Rotation from Flywheel End | Counterclockwise |

Stroke | 6.4 in |

Bore | 5.7 in |

Configuration | Vee 12, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Minimum Dry Weight | 6950 lb |

Minimum Length | 83.5 in |

Minimum Height | 60.9 in |

Maximum Length | 89.9 in |

Maximum Dry Weight | 7160 lb |

Maximum Height | 62.5 in |

Width | 60.2 in |

C32 IMO II STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Air cleaner

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- Programmable Low Idle (550 – 750 rpm)

- Programmable High Idle Limit for WOSR Ratings

- Electronic diagnostics and fault logging

- Engine and transmission monitoring (speed, temperature, pressure)

- Electronic fuel/air ratio control

- Engine Protection Mode for extended ambient conditions

- 70-pin customer connector

- Throttle Input signal options

- 0 – 5 Volts

- 4 – 20 mA

- PWM (Pulse Width Modulated)

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Jacket Water (JW) and SCAC Heat Exchangers Shell & Tube for HEX cooled engines

- SCAC pump, gear driven

- Jacket water pump, gear driven

- Sea water pump, bronze impeller, gear driven, when selected for Hex cooled engines

- Sea water Pump & JW Heat Exchanger Connection: 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange Connection

- Keel Connections: 76.2 mm (3in) ID Standard 4 Bolt

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 4 Bolt 130 mm (5.12 in) diameter flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- SAE standard rotation (CCW facing exciter end)

- Flywheel Housing: SAE No. 0, Flywheel: 18 inch, 136 teeth

FUEL SYSTEM

- Duplex Fuel Filters, Spin-on, RH & LH service

- Fuel connections size: r driven

- Plate-type fuel cooler installed behind Aftercooler Shunt Tank

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Simplex Oil Filters, RH or LH service

- Deep sump oil pan

- RH or LH service oil filler locations

- RH or LH service dipstick

- Oil pump, gear driven

MOUNTING SYSTEM

- Front support – 33 inches wide

POWER TAKE-OFFS

- Front Poly-V groove pulley (Quantity 1) for auxiliary drives

GENERAL

- Common electrical bonding point

- Engine does not ship with zinc components

C32 IMO II OPTIONAL EQUIPMENT

EXHAUST SYSTEM

- Dry Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

AIR INLET SYSTEM

- Air Inlet Adapter

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- Ammeter

CONTROL SYSTEM

- Load Sharing Attachment

- Instrument Panels

- Caterpillar Alarm Protection

- Fuel and Oil Shielding

FUEL SYSTEM

- Water Separator

GENERAL

- Fumes Disposal System

INSTRUMENTATION

- Instrument Panels

- OEM Wiring Harness

- Engine to Engine Harness

- Gauges

- Transmission Sensors

- Exhaust Temperature Sensors

LUBE SYSTEM

- Duplex Oil Filters

- Sump Pump

POWER TAKE-OFFS

- Rear Hydraulic Pump Drive

STARTING SYSTEM

- Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Dual Starting Motors (Electric and Air)

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

MOUNTING SYSTEM

- Front Support

- Rear Support

- Isolators Mounts

- Adapter Kits

PACKING

- Engine Protective Cover

- Storage Preservation

- Export Packing

Caterpillar Engine 58 – Auxiliary Engines C32 TIER 3

KEY SPECS

Minimum Rating

1047 BHP

Maximum Rating

1333 BHP

Aspiration

TTA

Overview

C32 ACERT auxiliary/generator set engines incorporate a separate circuit aftercooling system (SCAC) for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines also contribute to minimizing owning and operating costs. The EPA Tier 3, IMO II, EU Stage IIIA compliant ratings are available with heat exchanger or keel cooled options. Heat exchanger configurations have an optional front mounted sea water pump.

Key Features and Benefits

- Emissions: U.S. EPA Tier 3 compliant

- Worldwide Support: Extensive service network of dealers; Unparalleled service from authorized marine dealers

- Durability: Proven engine operating history; Performance iron with thousands of hours of validation testing for quality and durability

- Reliability: 60 months standard warranty

- Cooling System: Heat Exchanger or Keel Cooling; Heat exchanger configurations: optional front mounted sea water pump

- Aftercooling System: Separate circuit aftercooling system (SCAC): no seawater circulating through the aftercooler

PRODUCT SPECIFICATIONS FOR C32 TIER 3

POWER RATING

Minimum Rating | 1047 BHP |

Maximum Rating | 1333 BHP |

ENGINE SPECIFICATIONS

Aspiration | TTA |

Displacement | 1959 in³ |

Bore | 5.7 in |

Stroke | 6.4 in |

Rotation from Flywheel End | Counterclockwise |

Configuration | Vee 12, 4-Stroke-Cycle Diesel |

DIMENSIONS & WEIGHTS

Minimum Height | 60.9 in |

Maximum Height | 62.5 in |

Maximum Width | 60.2 in |

Maximum Dry Weight | 7160 lb |

Maximum Length | 89.9 in |

Minimum Dry Weight | 6950 lb |

Minimum Length | 83.5 in |

Minimum Width | 60.2 in |

C32 TIER 3 STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Air cleaner

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- Programmable Low Idle (550 – 750 rpm)

- Programmable High Idle Limit for WOSR Ratings

- Electronic diagnostics and fault logging

- Engine and transmission monitoring (speed, temperature, pressure)

- Electronic fuel/air ratio control

- Engine Protection Mode for extended ambient conditions

- 70-pin customer connector

- Throttle Input signal options

- 0 – 5 Volts

- 4 – 20 mA

- PWM (Pulse Width Modulated)

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Jacket Water (JW) and SCAC Heat Exchangers Shell & Tube for HEX cooled engines

- SCAC pump, gear driven

- Jacket water pump, gear driven

- Sea water pump, bronze impeller, gear driven, when selected for Hex cooled engines

- Sea water Pump & JW Heat Exchanger Connection: 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange Connection

- Keel Connections: 76.2 mm (3in) ID Standard 4 Bolt

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 4 Bolt 130 mm (5.12 in) diameter flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- SAE standard rotation (CCW facing exciter end)

- Flywheel Housing: SAE No. 0, Flywheel: 18 inch, 136 teeth

FUEL SYSTEM

- Duplex Fuel Filters, Spin-on, RH & LH service

- Fuel connections size: r driven

- Plate-type fuel cooler installed behind Aftercooler Shunt Tank

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Simplex Oil Filters, RH or LH service

- Deep sump oil pan

- RH or LH service oil filler locations

- RH or LH service dipstick

- Oil pump, gear driven

MOUNTING SYSTEM

- Front support – 33 inches wide

POWER TAKE-OFFS

- Front Poly-V groove pulley (Quantity 1) for auxiliary drives

GENERAL

- Common electrical bonding point

- Engine does not ship with zinc components

C32 TIER 3 OPTIONAL EQUIPMENT

EXHAUST SYSTEM

- Dry Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

AIR INLET SYSTEM

- Air Inlet Adapter

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- Ammeter

CONTROL SYSTEM

- Load Sharing Attachment

- Instrument Panels

- Caterpillar Alarm Protection

- Fuel and Oil Shielding

FUEL SYSTEM

- Water Separator

GENERAL

- FUMES DISPOSAL SYSTEM

INSTRUMENTATION

- Instrument Panels

- OEM Wiring Harness

- Engine to Engine Harness

- Gauges

- Transmission Sensors

- Exhaust Temperature Sensors

LUBE SYSTEM

- Duplex Oil Filters

- Sump Pump

POWER TAKE-OFFS

- Rear Hydraulic Pump Drive

STARTING SYSTEM

- Electric Starting Motors – Single 24 Volt

- Air Starting Motor

- Dual Starting Motors (Electric and Air)

- Air Start Accessories

- Starting Aids – JW Heaters

- Battery Sets – 24 Volt – Dry

MOUNTING SYSTEM

- Front Support

- Rear Support

- Isolators Mounts

- Adapter Kits

PACKING

- Engine Protective Cover

- Storage Preservation

- Export Packing

Caterpillar Engine 59 – Auxiliary Engines C32 TIER 3 / IMO II

KEY SPECS

Minimum Rating

314 BHP

Maximum Rating

1333 BHP

Aspiration

Turbocharged-aftercooled aspiration

Overview

Cat C32 Auxiliary / Diesel Electric Propulsion (US EPA Tier 3 / IMO II)

Key Features and Benefits

Scac: Separate-circuit aftercooling – no sea water in aftercooler

Fuel System: Reliable electronic controlled unit injector fuel system. Enhanced control of fuel injection optimized through crank timing and the A4 ECM technology. Advanced combustion technology to optimize fuel consumption and meet emissions without aftertreatment.

Power Reserve: Industry-leading power reserve

Certifications: Wide range of available Marine Society certifications

Warranty: Industry-leading warranty coverage for factory packaged components

Service: Global dealer network for service in any location

PRODUCT SPECIFICATIONS FOR C32 TIER 3 / IMO II

POWER RATING

Minimum Rating | 314 BHP |

Maximum Rating | 1333 BHP |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-aftercooled aspiration |

Emissions | U.S. EPA Tier 3 / IMO II emissions certified |

Displacement | 1959 in³ |

Bore | 5.71 in |

Stroke | 6.38 in |

Rotation | Counterclockwise from flywheel end |

Configuration | Vee 12, 4-stroke-cycle diesel |

Oil Change Interval | 750 hrs |

Flywheel Housing | SAE No. 0 with SAE No. 18 flywheel (136 teeth) |

Refill Capacity | Lube Oil System w/Oil filter change: 146 L (38.5 gal) |

Governor | Electronic (A4 ECM) |

Rated Engine Speed | 1800 rpm |

Cooling | Heat exchanger or keel cooled |

DIMENSIONS & WEIGHTS

Minimum Length | 83.9 in |

Maximum Width | 57.3 in |

Minimum Engine Dry Weight | 6950 lb |

Minimum Width | 57.1 in |

Minimum Height | 59.3 in |

Maximum Length | 89.8 in |

Maximum Engine Dry Weight | 7160 lb |

Maximum Height | 63.5 in |

C32 TIER 3 / IMO II STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooled (SCAC)

CONTROL SYSTEM

- 24V control system

COOLING SYSTEM

- Heat exchanger or Keel Cooling

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

FUEL SYSTEM

- Duplex fuel filters with hybrid fuel lines

- Fuel transfer and priming pump

LUBE SYSTEM

- Oil fill, simplex filter and dipstick

- Deep or shallow sump oil pan

MOUNTING SYSTEM

- Adjustable front support mounting system

GENERAL

- Right or left hand service sides

- Customer wiring and service tool connector

C32 TIER 3 / IMO II OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Closed crankcase fumes disposal

ALARM AND PROTECTION

- MECP I control panel

- MGCP II or MGCP IIIB control panel with Cat® Alarm and Protection System

CHARGING SYSTEM

- Charging alternator

FUEL SYSTEM

- Primary fuel filter with water separator, fuel cooler

LUBE SYSTEM

- Duplex oil filters

POWER TAKE-OFFS

- Front drives including stub shaft and pump drive

- Rear SAE A or B pump drives

STARTING SYSTEM

- Starting motors – air, electric or dual

Caterpillar Engine 60 – Auxiliary Engines C32 IMO III

KEY SPECS

Minimum Rating

1047 BHP

Maximum Rating

1332 BHP

Aspiration

Turbocharged-aftercooled

Overview

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (IMO III)

Key Features and Benefits

Emissions: Utilizes SCR Technology to enable IMO III emission regulations compliance while lowering operational costs

Control Strategy: Utilizes closed loop air assisted DEF dosing control strategy that delivers: Highest efficiency mixing and control to lower operational costs; Extends emissions useful life; Ensures compliance; Flexible to urea quality

Fuel System: Enhanced control of fuel injection optimized through crank timing and the A5 ECM technology

Power Reserve: Industry leading power reserve

Certifications: Wide range of available Marine Society certifications

Warranty: Industry-leading warranty coverage for factory packaged components

Service: Global dealer network for service in any location

PRODUCT SPECIFICATIONS FOR C32 IMO III

POWER RATING

Minimum Rating | 1047 BHP |

Maximum Rating | 1332 BHP |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-aftercooled |

Emissions | IMO III emissions certified (SCR required) |

Displacement | 1959 in³ |

Stroke | 6.38 in |

Rotation | Counterclockwise from flywheel end |

Bore | 5.71 in |

Configuration | Vee 12, 4-stroke-cycle diesel |

Cooling | Heat exchanger or keel cooled |

Flywheel Housing | SAE No. 0 with SAE No. 18 flywheel (136 teeth) |

Rated Engine Speed | 1500 rpm |

Governor | Electronic (A5 ECM) |

Oil Change Interval | 750 hrs – deep pan |

Refill Capacity | Lube Oil System w/ oil filter change: 146 L (38.5 gal) – deep pan |

DIMENSIONS & WEIGHTS

Maximum Engine Dry Weight | 7160 lb |

Minimum Height | 59.3 in |

Minimum Engine Dry Weight | 6950 lb |

Minimum Width | 57.1 in |

Maximum Length | 89.8 in |

Minimum Length | 83.9 in |

Maximum Width | 57.3 in |

Maximum Height | 63.5 in |

CLEAN EMISSIONS MODULE (CEM) – DIMENSIONS

6 Brick Z-Flow – Weight | 1246 lb |

6 Brick U-Flow – Width | 56.9 in |

6 Brick U-Flow – Length | 85 in |

6 Brick U-Flow – Height | 23.5 in |

Dosing Cabinet – Width | 18.8 in |

6 Brick Z-Flow – Height | 23.5 in |

Dosing Cabinet – Weight | 209 lb |

6 Brick Z-Flow – Length | 147.7 in |

6 Brick U-Flow – Weight | 1235 lb |

Dosing Cabinet – Length | 37.4 in |

Dosing Cabinet – Height | 22.8 in |

6 Brick Z-Flow – Width | 43.5 in |

C32 IMO III STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooled (SCAC)

- Closed crankcase fumes disposal

CONTROL SYSTEM

- 24V control system

COOLING SYSTEM

- Heat exchanger or Keel Cooling

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

FUEL SYSTEM

- Duplex fuel filters with hybrid fuel lines

- Shipped loose primary fuel filter with water separator

- Fuel transfer and priming pump

LUBE SYSTEM

- Oil fill, simplex filter and dipstick

- Deep or shallow sump oil pan

MOUNTING SYSTEM

- Adjustable front support mounting system

GENERAL

- Right or left hand service sides

- Customer wiring and service tool connector

C32 IMO III OPTIONAL EQUIPMENT

ALARM AND PROTECTION

- MECP I control panel

- MECP III control panel with Cat® Alarm and Protection System

EXHAUST SYSTEM

- Water-in-fuel and exhaust temperature sensors

- Muffler

CHARGING SYSTEM

- Charging alternator

FUEL SYSTEM

- Manual or electric fuel priming pump

- Fuel cooler

LUBE SYSTEM

- Duplex oil filters

POWER TAKE-OFFS

- Front drives including stub shaft and pump drive

- Rear SAE A or B pump drives

STARTING SYSTEM

- Starting motors – air, electric or redundant

Caterpillar Engine 61 – Auxiliary Engines C32 TIER 4 / IMO III

KEY SPECS

Minimum Rating

400 BHP

Maximum Rating

1333 BHP

Aspiration

Turbocharged-aftercooled

Overview

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (US EPA Tier 4 / IMO III)

Key Features and Benefits

- Emissions: Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs

- Control Strategy: Utilizes closed loop air assisted DEF dosing control strategy that delivers: Highest efficiency mixing and control to lower operational costs; Extends emissions useful life; Ensures compliance; Flexible to urea quality

- Fuel System: Enhanced control of fuel injection optimized through crank timing and the A5 ECM technology

- Power Reserve: Industry leading power reserve

- Certifications: Wide range of available Marine Society certifications

- Warranty: Industry-leading warranty coverage for factory packaged components

- Service: Global dealer network for service in any location

PRODUCT SPECIFICATIONS FOR C32 TIER 4 / IMO III

POWER RATING

Minimum Rating | 400 BHP |

Maximum Rating | 1333 BHP |

ENGINE SPECIFICATIONS

Aspiration | Turbocharged-aftercooled |

Emissions | U.S. EPA Tier 4 Final certified, IMO III emissions certified (SCR required) |

Rotation | Counterclockwise from flywheel end |

Bore | 5.71 in |

Configuration | Vee 12, 4-stroke-cycle diesel |

Stroke | 6.38 in |

Displacement | 1959 in³ |

Oil Change Interval | 750 hrs – deep pan |

Rated Engine Speed | 1800 rpm |

Governor | Electronic (A5 ECM) |

Refill Capacity | Lube Oil System w/ oil filter change: 146 L (38.5 gal) – deep pan |

Cooling | Heat exchanger or keel cooled |

Flywheel Housing | SAE No. 0 with SAE No. 18 flywheel (136 teeth) |

DIMENSIONS & WEIGHTS

Maximum Width | 57.3 in |

Maximum Height | 63.5 in |

Maximum Engine Dry Weight | 7160 lb |

Minimum Engine Dry Weight | 6950 lb |

Minimum Length | 83.9 in |

Maximum Length | 89.8 in |

Minimum Width | 57.1 in |

Minimum Height | 59.3 in |

CLEAN EMISSIONS MODULE (CEM) – DIMENSIONS

6 Brick U-Flow – Length | 85 in |

C32 TIER 4 / IMO III STANDARD EQUIPMENT

AIR INLET SYSTEM

- Separate circuit aftercooled (SCAC)

- Closed crankcase fumes disposal

CONTROL SYSTEM

- 24V control system

COOLING SYSTEM

- Heat exchanger or Keel Cooling

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

FUEL SYSTEM

- Duplex fuel filters with hybrid fuel lines

- Shipped loose primary fuel filter with water separator

- Fuel transfer and priming pump

LUBE SYSTEM

- Oil fill, simplex filter and dipstick

- Deep or shallow sump oil pan

MOUNTING SYSTEM

- Adjustable front support mounting system

GENERAL

- Right or left hand service sides

- Customer wiring and service tool connector

C32 TIER 4 / IMO III OPTIONAL EQUIPMENT

ALARM AND PROTECTION

- MECP I control panel

- MECP III control panel with Cat® Alarm and Protection System

EXHAUST SYSTEM

- Water-in-fuel and exhaust temperature sensors

- Muffler

CHARGING SYSTEM

- Charging alternator

FUEL SYSTEM

- Manual or electric fuel priming pump

- Fuel cooler

LUBE SYSTEM

- Duplex oil filters

POWER TAKE-OFFS

- Front drives including stub shaft and pump drive

- Rear SAE A or B pump drives

STARTING SYSTEM

- Starting motors – air, electric or redundant

Caterpillar Engine 62 – Auxiliary Engines 3512E

KEY SPECS

Aspiration

TA

Power Range

732-2399 bhp (546-1789 bkW)

Emissions

U.S. EPA Tier 4 Final, IMO III

Overview

The 3512E marine auxiliary engine is now available in a wide range of ratings that meet U.S. EPA Tier 4 Final and IMO III marine emissions regulations. As the commercial marine industry adjusts their operations to meet U.S. EPA Tier 4 Final and IMO III emissions standards, Caterpillar Marine has introduced a solution built to maximize performance while meeting regulations. Caterpillar’s combination of a fuel-efficiency-optimized engine and a selective catalytic reduction (SCR) aftertreatment system is a solution that not only reduces NOx emissions, but can also lower a customer’s owning and operating costs in the process.

Key Features and Benefits

- Emissions: Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs, IMO III emissions compliant

- Utilizes Closed Loop Air Assisted Def Dosing Control Strategy: Highest efficiency mixing and control to lower operational costs, extends emissions useful life, ensures compliance, flexibility regarding urea quality

- Advanced Engine Combustion Design: Advanced engine combustion design process utilizing optimum configurations and cylinder geometry for maximum engine efficiency

- Enhanced Control of Fuel Injection: Enhanced control of fuel injection optimized through crank timing and thelatest A5 ECM technology

- Enhanced Fuel Delivery: Optimal fuel injector nozzle geometry and electronic injection control for improved fuel delivery

- Increased Durability and Higher Engine Duty Cycle Capability: Strengthened cylinder heads and valves for increased durability and peak cylinder pressure capability resulting in higher engine duty cycle capability

- Caterpillar Warranty: Industry-leading warranty coverage for factory packaged components

- Global Dealer Network: No matter where or when, our extensive global dealer network is ready to provide support.

PRODUCT SPECIFICATIONS FOR 3512E

ENGINE SPECIFICATIONS

Aspiration | TA |

Emissions | U.S. EPA Tier 4 Final, IMO III |

Bore | 6.69 in |

Displacement | 3574 in³ |

Stroke | 8.46 in |

Rotation from Flywheel End | Counterclockwise |

Configuration | Vee 12, 4-Stroke-Cycle Diesel |

POWER RATING

Power Range | 732-2399 bhp (546-1789 bkW) |

DIMENSIONS & WEIGHTS

Maximum Width | 81.9 in |

Minimum Width | 71.2 in |

Maximum Height | 91.9 in |

Minimum Height | 91.9 in |

Minimum Dry Weight | 18025 lb |

Maximum Length | 125.4 in |

Minimum Length | 104.2 in |

3512E STANDARD EQUIPMENT

AIR INLET SYSTEM

- Corrosion-resistant aftercooler core

CONTROL SYSTEM

- Dual A5 engine control modules with electronic unit injection and low pressure fuel system

EXHAUST SYSTEM

- Dual turbochargers with water-cooled bearings and heat shields

GENERAL

- Vibration damper and guard

- Meets SOLAS regulations

FUEL SYSTEM

- Duplex Fuel and Oil Filtration

COOLING SYSTEM

- Auxiliary fresh water pump

- Gear Driven, centrifugal jacket water pump with 40% more capacity

Caterpillar Engine 63 – Auxiliary Engines 3516E

KEY SPECS

Aspiration

TA

Power Range

787-3175 bhp (587-2368 bkW)

Emissions

U.S. EPA Tier 4 Final, IMO III

Overview

The 3516E marine auxiliary engine is now available in a wide range of ratings that meet U.S. EPA Tier 4 Final and IMO III marine emissions regulations. As the commercial marine industry adjusts their operations to meet EPA Tier 4 Final and IMO III emissions standards, Caterpillar Marine has introduced a solution built to maximize performance while meeting regulations. Caterpillar’s combination of a fuel-efficiency-optimized engine and a selective catalytic reduction (SCR) aftertreatment system is a solution that not only reduces NOx emissions, but can also lower a customer’s owning and operating costs in the process.

Key Features and Benefits

- Emissions: Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs, IMO III emissions compliant

- Utilizes Closed Loop Air Assisted Def Dosing Control Strategy: Highest efficiency mixing and control to lower operational costs, extends emissions useful life, ensures compliance, flexibility regarding urea quality

- Advanced Engine Combustion Design: Advanced engine combustion design process utilizing optimum configurations and cylinder geometry for maximum engine efficiency

- Enhanced Control of Fuel Injection: Enhanced control of fuel injection optimized through crank timing and the latest A5 ECM technology

- Enhanced Fuel Delivery: Optimal fuel injector nozzle geometry and electronic injection control for improved fuel delivery

- Increased Durability and Higher Engine Duty Cycle Capability: Strengthened cylinder heads and valves for increased durability and peak cylinder pressure capability resulting in higher engine duty cycle capability

- Caterpillar Warranty: Industry-leading warranty coverage for factory packaged components

- Global Dealer Network: No matter where or when, our extensive global dealer network is ready to provide support

PRODUCT SPECIFICATIONS FOR 3516E

ENGINE SPECIFICATIONS

Aspiration | TA |

Emissions | U.S. EPA Tier 4 Final, IMO III |

Stroke | 8.46 in |

Displacement | 4765 in³ |

Configuration | Vee 16, 4-Stroke-Cycle Diesel |

Bore | 6.69 in |

Rotation from Flywheel End | Counterclockwise |

POWER RATING

Power Range | 787-3175 bhp (587-2368 bkW) |

DIMENSIONS & WEIGHTS

Minimum Width | 72.8 in |

Dry Weight | 22060 lb |

Height | 90.9 in |

Length | 146.6 in |

Maximum Width | 87.9 in |

3516E STANDARD EQUIPMENT

AIR INLET SYSTEM

- Corrosion-resistant aftercooler core

CONTROL SYSTEM

- Dual A5 engine control modules with electronic unit injection and low pressure fuel system

COOLING SYSTEM

- Auxiliary fresh water pump

- Gear Driven, centrifugal jacket water pump with 40% more capacity

EXHAUST SYSTEM

- Dual turbochargers with water-cooled bearings and heat shields

FUEL SYSTEM

- Duplex Fuel and Oil Filtration

GENERAL

- Vibration damper and guard

- Meets SOLAS regulations

Caterpillar Engine 64 – Auxiliary Engines C280

KEY SPECS

Minimum Rating

2320 BHP

Maximum Rating

7268 BHP

Aspiration

TA

Overview

Cat C280 Marine Auxiliary Engines

Key Features and Benefits

- A3 Ecu – Advantages: CAN J1939 data link Waterproof connectors, Maintenance-free, Backup ECU for redundant governing

- A3 Ecu – Electronic Advantages: Load feedback, Programmable droop, Adjustable gain, Adjustable fuel/air ratio control, Histograms of engine operation, Cat Messenger display presents diagnostics and other engine parameters

- A3 Ecu – Data Advantages Through J1939 Link: Engine speed, Boost pressure, Throttle position, Fuel consumption rate, Inlet manifold temperature, Diagnostic codes and events, Configuration, Desired engine speed, Battery voltage, Engine load, Lifetime totals — engine hours, fuel burned, idle fuel, idle hours, Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

- Customer Interface Panel: Interfaces with standard Cat® Marine Monitoring System (PLC in Price List) Provides visual indication of ECU functionality, Accepts 4 — 20 mA or PWM remote throttle speed input, Marine alarm and protection

- Electronic Unit Injectors: “Drop-in” installation, No threaded fuel connections, High pressure inside injector only, Does not require double wall fuel lines or leak collection device, Injector synchronization not required

PRODUCT SPECIFICATIONS FOR C280

POWER RATING

Minimum Rating | 2320 BHP |

Maximum Rating | 7268 BHP |

ENGINE SPECIFICATIONS

Aspiration | TA |

Configuration | In-Line 6, Vee 8, Vee 12, Vee 16, 4-Stroke-Cycle Diesel |

Bore | 11 in |

Stroke | 11.8 in |

DIMENSIONS & WEIGHTS

Maximum Width | 69 in |

Minimum Height | 108 in |

Minimum Dry Weight | 34496 lb |

Maximum Height | 140 in |

Minimum Width | 67 in |

Minimum Length | 145 in |

Maximum Length | 197 in |

Maximum Dry Weight | 62832 lb |

C280 STANDARD EQUIPMENT

AIR INLET SYSTEM

- R INLET SYSTEM Aftercooler, fresh water, corrosion resistant coated (air side) Air inlet shutoff Breather, crankcase, top-mounted Turbocharger, rear-mounted, engine oil lubricated

CONTROL SYSTEM

- Single Caterpillar A-III Electronic Engine Control Modules with Electronic Unit Injector Fuel System Rigid Wiring Harness (10 amp 24volt power required to drive Electronic Engine Control Modules)

COOLING SYSTEM

- Engine coolant water drains

EXHAUST SYSTEM

- Dry, gas tight, exhaust manifold

FUEL SYSTEM

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38 degrees C) Fuel transfer pump (mounted on left hand side) Duplex fuel filters Electronically Controlled Unit Injectors

LUBE SYSTEM

- Centrifugal oil filters with single shutoff. Service side engine mounted on cylinder block inspection covers. Includes installed oil lines and single shutoff valve. Filters centrifuge bypass oil from the main lubricating oil pump. Can be serviced with the engine running. Oil filler and dipstick Valve, oil pressure regulating Valves, crankcase explosion relief

GENERAL

- Paint, Caterpillar yellow Pumps, gear driven: fuel, oil, jacket water, aftercooler/oil cooler water

SVCE TOOLS/SHIP PROT/FACTORY SUPPORT

- Service literature. Included standard with each engine are two (2) complete sets of service literature listed below: 1. Custom parts book CD (serial number specific) 2. Service manual, which includes: Operation & Maintenance, Specifications, Systems Operation, Testing and Adjusting, Disassembly and Assembly manual. Available in paper media and English language only. 3. Technical manual (parts/service information for special equipment). Available in paper media in English language only. NOTE: Custom parts book CD and service manual can be re-ordered through the normal Caterpillar literature ordering system. The technical manual can only be re-ordered through the Project Services at the Caterpillar Lafayette Engine Center facility.

C280 OPTIONAL EQUIPMENT

AIR INLET SYSTEM

- Air Cleaners

COOLING SYSTEM

- Jacket Water Heaters

- Heat Recovery System

- Heat Recovery Thermostats

- Cooling System Connection Groups

- De-Aerator

CONTROL SYSTEM

- Load Sharing module

- Direct Rack Module

EXHAUST SYSTEM

- Outlet Expander

- Flexible Exhaust Fittings

- Weld Flange – Optional

FUEL SYSTEM

- Fuel Priming Pump

- Duplex Primary Fuel Strainer

- Fuel System Connections

LUBE SYSTEM

- Oil Pan Drain Valve

- Prelubrication Connections

- Lube Oil Heater

MOUNTING SYSTEM

- Vibration Isolators

MARINE SOCIETY REQUIREMENTS

- Spray shielding

PROTECTION SYSTEM

- PLC Monitoring System Options

- ECP Relay System Options

- ECP Mechanical Gauge Instrument Panel

- Turbocharger Speed Sensor

- Cylinder Pressure Relief Valve

- Oil Mist Detector

- Protection System Components

- Magnetic Pickup

SPARE PART KITS

- Intake and Air System

- Basic Engine

- Cylinder Head

- Fuel System

- Cooling System

- Instrumentation

- Cylinder Valve Kits

ENGINE TESTING

- Basic System Testing

- Special Witness Test

- Torsional Vibration Analysis

SERVICE TOOLS / SHIPPING PROTECTION / FACTORY SUPPORT

- Commissioning

- Service Tools

- Factory Packaging

- Shipping Protection-Shrink Wrap or Tarp

- Shipping Protection-Export Boxing

- AID Emblem

- Storage Preservation

Caterpillar Engine 65 – Controls MPC100

KEY SPECS

Overview

The Cat® MPC100 is the new Propulsion Control System solution designed for commercial vessels and yachting.

It is the ideal control system for single and twin-propeller applications, providing the captain reliable control of his vessel at any given time even in the harshest marine environments. Particular attention has been paid to the design and ergonomics, which not only adapts to a luxurious environment but also provides ease of operation and unmatched user experience. MPC100 is featuring extensive capabilities for integration into the vessel’s ecosystem.

Key Features and Benefits

- Supports 12 and 24VDC powered applications

- Available for all electronically controlled Cat Marine Propulsion Engines

- Compatible with all major Marine transmissions

- Control from up to 8 Command Stations

- Built-in Control of the Engine, Transmission incl. Trolling Valve

- Mode Selector incl. Warm-up, Trolling, Advanced Trolling, Slow Vessel and Cruising Modes

- Synchronization Mode for Twin Propeller Operation using Single Lever

- Engine Start Interlocks

- Highly configurable for multiple powertrain configurations

- Easy Plug & Play Installation supported by Cat ET (Electronic Technician)

- Optional backup control panel

Ergonomic Handle and Lever: Comfortable to grip in all ways and directions

Exchangeable Handle: Top surface of handle is possible to change to fit the environment and helm design

Safe Operation: Buttons are recessed to prevent unintentional actuation

Clear Haptics: Rubber buttons with metal domes give a distinct and clear haptic feedback

Small, Rectangular Footprint: Requires less helm panel real estate and facilites installation

Solid Chrome: Resisting weather challenges

Black Head Body: Fits with other components in the helm and makes the conrol blend in

Glass Interface: Consistent with other components in a glass bridge helm

Distinct, Dynamically Adaptable User Interface: Only shows the information that is relevant and vital at each specific time

MPC100 STANDARD EQUIPMENT

MCL100 – INTEGRATED MARINE CONTROL LEVER HEAD

- Small footprint offering an integrated mode selector

- Built-in display using dynamic user interface enhancing user experience

- General alarm status indicators in the lever head itself

MPL100 – MARINE PALM BEACH LEVER ASSEMBLY

- Interface unit to the larger side-mounted handles

MCD100 – MARINE CONTROL DISPLAY

- Multi-purpose control device with integrated backup control unit used for the palm beach lever head integration point as well as the interface to the advanced lever head.

MCP100/300 – MARINE CONTROL PROCESSOR

- Redundant control processor unit for controlling single or twin-powertrain configurations, incl. engine transmissions and trolling valves

- Configurable interface for integration into vessel’s ecosystem

CMD – CAT MARINE DISPLAYS

- CMD5, CMD8, and CMD13 with easy access to operating data and alarm notification for engine and powertrain control systems

HARNESSING

- Standardized control and engine room harnessing available in various lengths