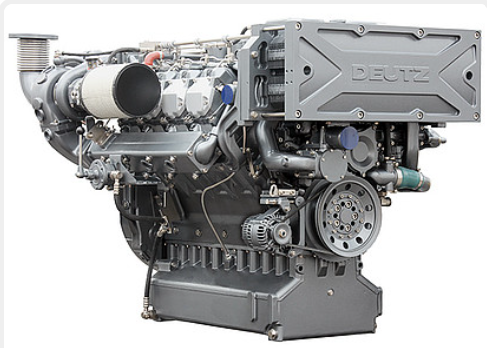

An air compressor is a vital equipment on-board in the engine room. It is used for starting low and medium-speed diesel engines. While a single air compressor is enough for tiny vessels, a large ship may have multiple air compressors to regulate the operations. Therefore, the DEUTZ Air Compressor Cylinder Head Kit plays a crucial role in DEUTZ marine engine maintenance.

Explore how to take care of the DEUTZ air compressor cylinder heads in this maintenance and troubleshooting guide.

Tips for Diesel Engine Air Compressor Maintenance

#1. Check the Manufacturer’s Instructions

DEUTZ Air compressor configurations may vary from one model to another. All original parts carry a maintenance instruction manual for the ship owners. It is vital to schedule an appointment with certified marine engineers for maintenance at regular intervals to avoid breakdowns.

#2. Monitor the Air Compressor Regularly

Breakdowns in air compressors can be unpredictable. Watching the cylinder parts’ performance is the best practice to detect the signs of problems early. Here are the measures to ensure problem-free operations:

Check the lube oil level every day and consider refill when necessary.

Monitor the pressure and temperature of discharge at various stages.

Keep an eye on the engine running time.

#3. Change the Air Filters Cartridge When Necessary

A clean air filter ensures the functionality of the DEUTZ air compressor cylinder heads. Replace this part with a genuine air filter after 250 hours of operation. Moreover, this may be necessary at high air discharge temperatures.

#4. Always Keep the Screwed Connections Tight

The screws may loosen through vibrations and movement in the piston and other parts. DIY job is fine to tighten the screws when needed.

#5. Check the Air Compressor When Running for Long Hours

The best practice to keep the air compressors in good shape is limiting the running time to 3-4 hours on the MR tanker. If this period exceeds, it is mandatory to watch the parts for accurate functioning.

#6. Change the Lubricating Oils DEUTZ Air Compressor Cylinder Heads

Besides saving vital engine parts from frictional wear and tear, lube oils help regulate the temperature in the engine. Replace the lubrication oil at regular intervals (usually every 1000 hours or as advised by the marine specialists) to prevent overheating and air compressor malfunctioning.

First, run the compressor for some time to ensure sludge and particulate suspension.

Second, remove the drain plug to flush out the used oil and fill fresh oil.

Finally, clean the crankcase with a lint-free cloth. Check the bearing for wearing and other issues.

#7. Clean the Filter and the Oil Strainer

It is mandatory to clean the filter and the oil strainer mesh when changing the lube oil. This keeps the oil free from pollutants for a long time.

#8. Check the Valves for Leakage Issues

Leaking is more than oil wastage, resulting in wearing and grease deposits on the engine walls. Call a repair professional if any of the oil is leaking from the valves.

Do you want to buy an OEM DEUTZ Air Compressor Cylinder Head Kit?

Alfa Marine Spare Parts has got the stocks ready for your needs. Contact us with the DEUTZ diesel engine air compressor cylinder head part number by filling out the inquiry form.

Our sales representatives will reach out with a quote in less than 24 hours. We offer affordable rates and a comprehensive warranty on all spare parts. Our partners are based across various locations worldwide to ensure fast and efficient consignment delivery to your location.