What is an Aftercooler? Have you ever wondered how heavy-duty machinery keeps cool under intense pressure and heat? Enter the aftercooler – the unsung hero of industrial equipment.

At Alfa Marine Spare Parts, we understand the importance of reliable aftercoolers in maintaining optimal operating conditions for marine engines and systems.

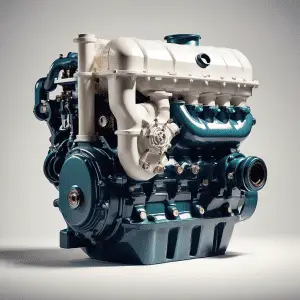

Marine engines are marvels of engineering, powering vessels across vast oceans. Several intricate components ensure smooth operation and optimal performance of these engines. One such component is the aftercooler, an essential part of marine engines like the Caterpillar C32.

What is an Aftercooler?

When it comes to optimizing the performance of air compression systems, aftercoolers play a crucial role. These often-overlooked components are essential for maintaining the efficiency and longevity of various industrial processes.

An aftercooler is a heat exchanger that cools and removes moisture from compressed air. When air is compressed, its temperature rises. This hot, humid air can cause problems in pneumatic systems, such as:

- Corrosion of pipes and equipment

- Reduced efficiency of air tools

- Growth of mold and bacteria in the compressed air system

Why Choose Aftercoolers from Alfa Marine Spare Parts?

Superior Performance:

In marine engines and systems, our aftercoolers reduce compressed air temperature effectively and prevent overheating.

Durability and Reliability:

Built to withstand harsh marine environments, our aftercoolers are crafted from high-quality materials and undergo rigorous testing to ensure durability and long-lasting performance.

Compatibility:

We offer a diverse range of aftercoolers compatible with various marine equipment, including fishing boats, yachts, vessels, towboats, and offshore marine applications.

Trusted Brands:

Choose from a wide selection of aftercoolers from reputable global brands such as Caterpillar, Cummins, Volvo Penta, and more, known for their excellence in engineering and reliability.

Expert Support:

Our experienced sales team is dedicated to providing personalized assistance, helping you find the perfect after-cooler solution tailored to your specific requirements.

Caterpillar Marine Aftercooler for C32 Engines: A Closer Look

Caterpillar is renowned for its high-quality marine engine components, and the aftercooler designed for the C32 engines exemplifies this commitment to excellence. Specifically engineered to meet the rigorous demands of marine applications, the Caterpillar marine aftercooler for C32 engines offers several key benefits:

Efficient Cooling

The aftercooler efficiently cools the compressed air, ensuring the engine operates within optimal temperature ranges even under heavy loads or in challenging marine environments.

Enhanced Performance

By delivering cooler, denser air to the engine, the aftercooler enhances combustion efficiency, resulting in improved power output and fuel efficiency.

Durability and Reliability

High-quality materials, rigorous testing, and rigorous inspection ensure the durability and reliability of Caterpillar marine aftercoolers.

Easy Maintenance

Designed for easy installation and maintenance, the aftercooler facilitates hassle-free servicing, minimizing downtime and maximizing vessel uptime.

Why is Aftercooler used in engines?

An aftercooler, also known as an intercooler, plays a crucial role in enhancing the performance of engines by efficiently cooling the compressed air before it enters the engine.

This process significantly increases the engine’s efficiency and power output by reducing the temperature of the intake air.

By lowering the temperature of the air, an aftercooler helps prevent pre-detonation and improves fuel combustion within the engine.

Moreover, aftercoolers are commonly used in turbocharged or supercharged engines to address the issue of increased heat generated during compression.

An aftercooler boosts engine efficiency as well as extends its lifespan by reducing wear and tear on components.

Overall, integrating an aftercooler into an engine’s design is essential for optimal performance, fuel efficiency, and reliability in demanding industrial applications.

When to add an aftercooler?

Aftercoolers are typically added to engines when there is a need to optimize performance, particularly in high-performance or high-demand applications.

You’ve optimized your air compressor system for maximum efficiency, but you’re still facing issues with high-discharge temperatures.

This is where an aftercooler comes into play. An aftercooler is a vital component that helps reduce the temperature of compressed air before it enters the distribution system.

The system is both better performing and more reliable as a result of preventing moisture condensation and potential damage.

So, when should you consider adding an aftercooler? Well, If you notice excessive heat buildup or if you operate in a high-temperature environment, it might be time to invest in an aftercooler.

When you use an aftercooler, you can effectively cool down compressed air and ensure consistent performance.

Remember, a well-maintained and properly functioning aftercooler can make a significant difference in the longevity and efficiency of your entire compressed air system.

How To Size An Aftercooler?

When sizing an aftercooler for your compressed air system, it’s essential to consider the flow rate and inlet temperature of the air.

Furthermore, it’s crucial to consider the pressure drop across the aftercooler when choosing the right size to guarantee optimal performance.

So, let’s actively calculate the heat load that the aftercooler needs to remove by factoring in ambient conditions and compressor efficiency.

Sizing an aftercooler involves determining the appropriate dimensions and specifications to effectively cool the compressed air for a given application. Here are the general steps to size an aftercooler:

Determine Required Cooling Capacity:

In order to attain the desired intake temperature, you must remove heat from the compressed air. This involves considering factors such as the compressor’s discharge temperature, ambient temperature, and desired intake temperature.

Select Cooling Medium:

Decide whether to use air or liquid (such as water or a water-glycol mixture) as the cooling medium based on available resources, space constraints, and cooling efficiency requirements.

Calculate Heat Transfer Rate:

Determine the heat transfer rate required to achieve the desired cooling capacity. This involves considering the selected cooling medium’s heat transfer characteristics and the aftercooler’s design.

Choose Aftercooler Type and Configuration:

You should select the type of aftercooler based on factors such as space, cooling efficiency requirements, and application limitations.

Consider Pressure Drop:

Account for the pressure drops across the aftercooler to ensure that it does not significantly affect the performance of the compressor or engine.

Size Aftercooler Components:

Determine the size and dimensions of the aftercooler components, including the heat exchanger surface area, tube or fin dimensions, and coolant flow rate (if applicable).

Account for Safety Factors:

Calculate safety factors to account for uncertainties in operating conditions, variations in ambient temperature, and fouling and scaling of the aftercooler.

Verify Design:

Validate the aftercooler design using simulation software or prototype testing to ensure that it meets the cooling requirements and performance expectations.

Moreover, these steps will help engineers size aftercoolers for industrial and automotive compressed air systems to optimize efficiency and performance.

Frequently Asked Questions

What is the purpose of an Aftercooler?

The aftercooler cools air from a turbocharger or supercharger before entering the engine’s intake manifold.

This cooling process increases the density of the air, resulting in improved combustion efficiency and increased power output.

What is an aftercooler in diesel engines?

In diesel engines, an aftercooler plays a crucial role in enhancing performance by cooling down the compressed air from the turbocharger. This is before it enters the engine’s intake system.

Reduced intake air temperatures increase air density, improving combustion efficiency and power delivery.

What is the Aftercooler on a turbo?

The aftercooler on a turbocharged system is a component designed to lower the temperature of the compressed air generated by the turbocharger before it enters the engine.

The aftercooler improves engine efficiency and performance by reducing air temperature.

Final Thought of What is an Aftercooler

As you navigate the vast seas of the marine industry, trust in Alfa Marine Spare Parts to be your steadfast companion on your journey.

At Alfa Marine, we understand the critical role that each component plays in the smooth operation of your vessel. That’s why we meticulously source, stock, and supply a comprehensive range of marine spare parts, including essential components like aftercoolers for engines such as the Caterpillar C32 and Cummins.

So, choose Alfa Marine Spare Parts for reliability, quality, and peace of mind on every voyage.