The 92 series, introduced in 1974, boasts a vast lineup of two-stroke marine engines. These engines, available in 6-, 8-, 12-, and 16-cylinder configurations, remain popular today for their simple user interface, robust power, and reliability. Expect superb efficiency and continued operation in stringent marine conditions. Additionally, the compact engines excel in performance and control during towing, manoeuvring, and hauling loads. The modules in this series are ideal for tugboats, fishing vessels, and offshore platforms.

This blog post highlights the primary models in the 92 series, specifically designed for marine applications, including engine specifications and basic maintenance recommendations.

Detroit Diesel 92 Series Engines Models for Marine Applications

The series 92 offers four models in the marine segment. When high power output is necessary in a stringent marine environment, these engines provide reliability, performance, and efficiency. These engines feature a simple design and ease of maintenance. There is sufficient scope for rebuilding these engines and repairing the parts at affordable costs.

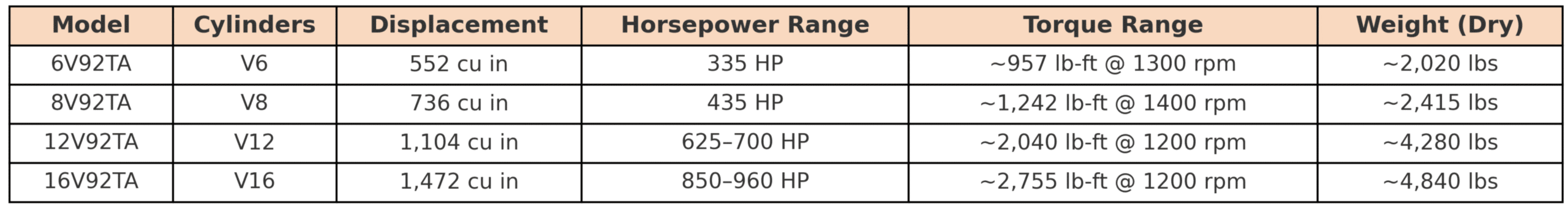

Engine Specifications

*The prefixes 6, 8, 12, and 16 denote the number of cylinders in the specific model. All engines feature a V-shaped block arrangement. All these engines boast a bore and stroke of approximately 4.84″ x 5.00″ and a 17:1 compression ratio when operating with a turbo system.

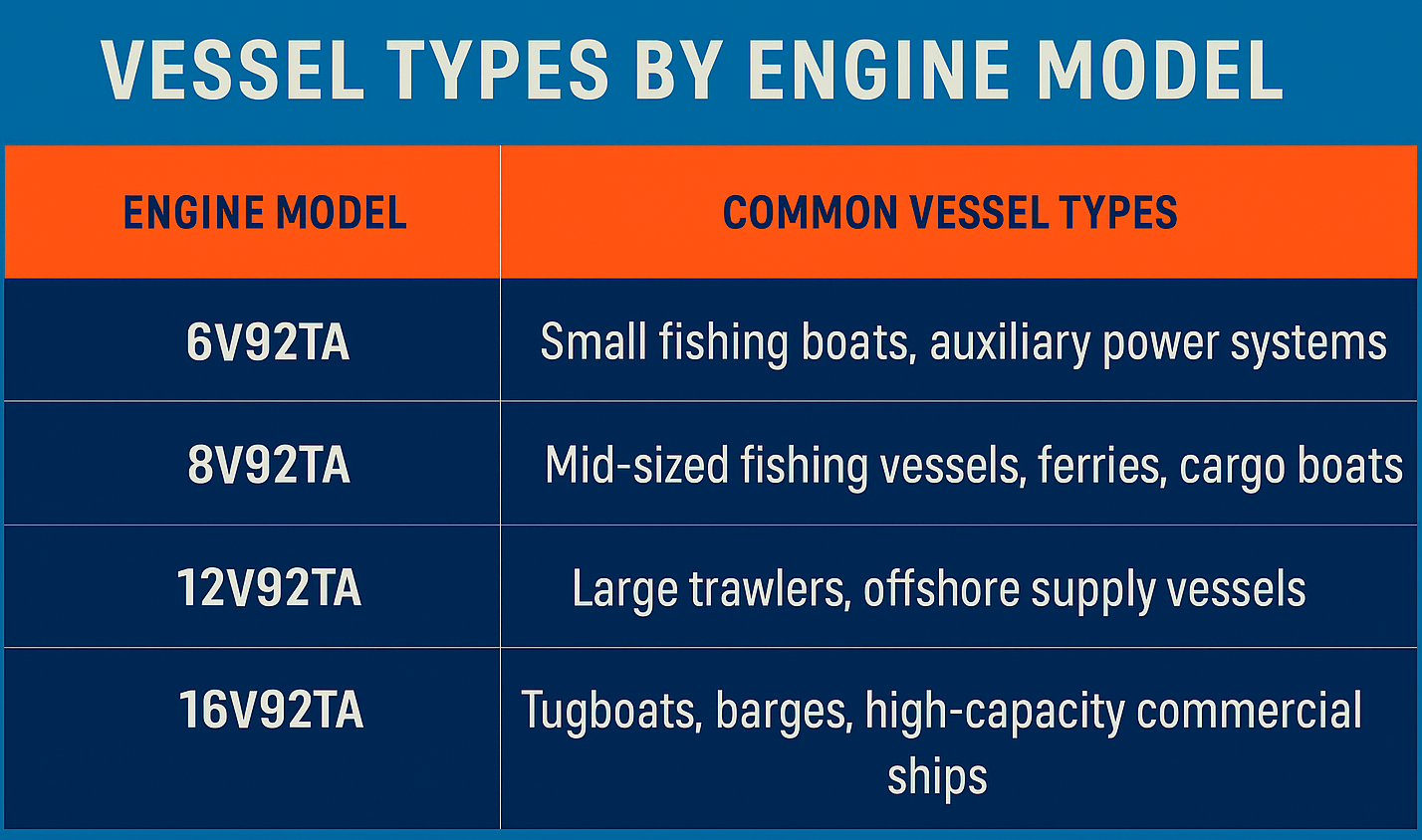

Supported Vessel Types

The Detroit Diesel series 92 marine engines are the best option for heavy-duty applications in a severe marine environment. These modules facilitate high-speed propulsion and torque necessary for towing and manoeuvring bulk carriers. It offers greater reliability and continued power efficiency for high-load operations, particularly during long-distance voyages.

- Large fishing carriers, including trawlers, longliners, and seiners

- Workboats

- Tugboats

- Barges

- Pleasure and recreational yachts

- Cargo ships

- Offshore supply watercrafts

- Passenger ferries

- Sports vessels

Cooling Options for 92 Series Diesel Engines

The 92 series engines offer flexibility to choose from two water-based closed-loop cooling systems –

#1. Heat Exchanger

The heater exchanger utilizes seawater to dissipate heat from the engine parts. The corrosion-resistant framework provides superb durability and protection against damage for years. However, the cooling system accumulates debris when the raw water pumps and freshwater circulation are in operation. Regular engine diagnosis, descaling treatment, and timely filter replacement are crucial for achieving top-notch performance without issues.

The cooling system is ideal for non-turbo modules, which are generally developed for light and short-term operations. It supports small and compact two-stroke engines with moderate power output and low exhaust gas emissions.

#2. Turbo-Aftercooling (TA)

The combined turbocharging-aftercooling technology is by far the most advanced cooling system for large vessels that deal with heavy workloads and weights. Integrating the aftercoolers is a safe option for maintaining the required engine temperature after exhaust gas treatment in the turbo system. The technology leverages permissible coolant fluid to eliminate heat from the air after processing the exhaust gases in the turbocharger. It boosts the efficiency of the safe combustion cycle and maximizes energy output. Continued aftercooling supports high-load operations in bulk watercrafts.

92 Series Marine Engine – Maintenance Recommendations

The maintenance schedules for Detroit Diesel 92 series engines can be grouped into various intervals, including daily, weekly, monthly, or by operation hour slabs (e.g., 250, 500 hours). Here is an overview of maintenance tasks for each of these intervals:

Daily Checking and Maintenance

- Check and fill the tank for an accurate engine oil level

- Clean the fuel tank, filters, and water separator to remove particulates and water

- Maintain accurate coolant level in the surge tank

- Check and fix the fasteners for precise tension

Additionally, vessel operators and technicians must inspect the seals, gaskets, O-rings, and fasteners for leaks and wear. Keep a watch on unusual noise, odour, and smoke quality.

Weekly Diagnosis and Care Measures

The weekly engine diagnosis and maintenance routine comprises inspection of the following parts:

- Air cleaner restriction indicator

- Battery electrolyte

- Specific gravity

- Apply lubricant to the throttle linkage adjustment

Inspect the exhaust system, pipes, and hoses for wear, cracks, and chipped parts.

Monthly / 250 Hours Machine Inspection and Overhaul

- Oil filter replacement

- Linkage lubrication

- Empty the old and contaminated engine oil and supply a fresh dose

- Clean the fuel tank and the strainers to remove debris deposits

- Diagnose the turbocharger both in on and off mode*

- Check for leaks around the blower

Run the turbocharger to check for unusual noise, vibration, excessive load, and leaks around lube oil pipes. Moreover, check the valve clearance, mounting bolts, and injector rack. These parts may require adjustment if there is any misalignment.

Conduct a demonstration vessel operation to verify the functionality of the sensors, switches, measuring gauges, indicators, alarm systems, and shutdown equipment.

For a comprehensive maintenance and replacement parts guide, consult a licensed marine engineer or a local service provider.

Buy Detroit Diesel Engines and Spare Parts

Do you want to purchase marine engines from Detroit Diesel?

Alfa Marine Spare Parts is one of the leading sellers offering the entire range of Detroit Diesel engines. Additionally, we sell an extensive collection of marine engines, spare parts, overhaul kits, maintenance kits, electrical systems, air starters, and other vessel accessories from renowned brands. Buy genuine OEM parts by Cat, Cummins, Deutz, Doosan, Perkins, Scania, Yanmar, and more.

Please don’t hesitate to contact us if you require assistance with replacement parts, upgrade options, or retrofit projects. Our team works closely with shipbuilders, repair service providers, and offshore units.