Few names are as well-known in the world of industrial and heavy equipment as Caterpillar Inc. In the mining, development, and energy enterprises, Caterpillar has gained notoriety for advancement and constancy throughout its over 90-year history.

Present-day gear configuration puts serious areas of strength for an on fuel economy for settling both monetary and natural issues.

Basically, the fuel inoculation siphon, a fundamental part that controls the specific measure of gas conveyed to the motor’s ignition chambers, is at the center of fuel economy.

This article takes a gander at the numerous ways that Caterpillar’s fuel injection pumps add to the most ideal fuel economy and execution.

It additionally takes a gander at the plan, advantages, and impacts these pumps have on motor execution.

Understanding Caterpillar Fuel Injection Pump

gas injection pumps direct the sum and timing of gas conveyed to a motor, going about as the watchmen of the fuel framework.

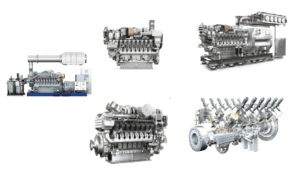

Moreover, their basic role is to work with productive burning by scattering and atomizing fuel into the ignition chambers. Two main types of fuel injection pumps dominate the industry: electronic and mechanical.

Diesel engines have traditionally used mechanical fuel inoculation pumps, which run on a mechanical linkage system. They depend on the engine’s motion to power the pump, which controls fuel flow according to load and engine speed.

By using electronic control units (ECUs) to precisely modify fuel supply based on real-time sensor data, electronic fuel injection pumps, on the other hand, offer a more sophisticated technique.

Contemporary engines favor electronic pumps for their advanced precision, allowing for excellent fuel economy and pollution management.

It is difficult to overstate the significance of fuel inoculation pumps for motor execution. They straightforwardly affect discharge levels, power creation, and fuel exercise.

Fuel injection pumps are essential for optimizing engine efficiency and minimizing environmental impact by ensuring precise fuel delivery in diverse operating conditions.

The Role of Caterpillar Fuel Injection Pump

Fuel injection pump innovation is just a single illustration of Caterpillar’s devotion to development. Caterpillar designs fuel inoculation pumps to withstand the demanding requirements of heavy-duty applications. They incorporate many highlights and advances that boost trustworthiness and execution.

Caterpillar designs its fuel injection pumps for durability and accuracy. Even in challenging working settings, long-term dependability and precise tolerances are guaranteed by advanced materials and production processes. Caterpillar also uses its electronic control systems to improve the responsiveness and precision of fuel distribution.

The fact that Caterpillar fuel injection pumps are integrated with Caterpillar engines and equipment is one of their main benefits. Caterpillar assures smooth compatibility and optimal performance by developing pumps that are especially suited to the performance attributes of their engines. This all-encompassing strategy sets Caterpillar apart from rivals and offers clients a complete answer for their power requirements.

Ensuring Fuel Efficiency with Caterpillar Fuel Injection Pump

Caterpillar’s engineering philosophy places a strong emphasis on fuel economy, and this is also true of their fuel injection pumps.

Optimization of Caterpillar Fuel Injection Pumps On Fuel Consumption

The fuel consumption of Caterpillar fuel inoculation pumps is carefully adjusted to maximize performance under a variety of operating circumstances.

These pumps provide effective combustion and little fuel waste by carefully regulating the amount, timing, and pressure of the fuel supply.

Caterpillar pumps ensure precise fuel delivery, promoting full combustion and reducing emissions. Their electronic control systems continuously adjust fuel supply for optimal performance and economy.

Impact of Fuel Injection Pumps on Engine Efficiency and Emissions

Caterpillar fuel injection pumps fundamentally affect emissions and engine efficiency. These pumps augment power production, pollution of the executives, and combustion efficiency by giving exact fuel metering and injection timing.

Engines can run as productively as conceivable under various working situations because of Caterpillar fuel injection pumps, which diminish poisons and fuel consumption while expanding power and efficiency. These pumps meet strict emissions regulations without sacrificing stability or performance.

Fuel Efficiency Improvements

Several case studies and practical demonstrations showcase the fuel economy improvements achievable with Caterpillar fuel injection pumps.

Caterpillar engines, equipped with high-level fuel injection systems, have significantly reduced fuel consumption and operating costs across various applications, from mining trucks to marine vessels.

An Australian mining company cut fuel consumption and operating costs by 10% by upgrading its haul trucks with Caterpillar engines and fuel injection pumps. Simila

rly, a European shipping company achieved a 15% decrease in emissions and fuel consumption by outfitting its vessels with Caterpillar marine engines and fuel injection systems.

So, these illustrations demonstrate the observable advantages of Caterpillar fuel inoculation pumps in terms of financial savings, ecological responsibility, and fuel economy.

Maintenance and Optimization

Fuel injection pumps should be appropriately kept up to work long term. Perceiving this, Caterpillar offers clients broad help and instruments to assist them with further developing the fuel framework on their hardware.

Fuel injection pumps need standard support and examination to distinguish any issues almost immediately and make a fitting move.

Moreover, Caterpillar’s extensive global network of dealers and service facilities provides expert maintenance services, including diagnostics, repairs, and part replacement.

Caterpillar gives supportive exhortation on expanding fuel economy using suitable gear activity and the board notwithstanding preventive upkeep. Specialized devices and instructional classes give administrators and support staff the ability they need to improve hardware execution while utilizing minimal measure of fuel.

Future Developments and Innovations

With an eye on the future, Caterpillar is currently at the front line of fuel injection pump innovation, continuously searching for better approaches to advance and turn out to be better.

Moreover, the goals of ongoing research include better fuel delivery precision, durability, and compatibility with alternative fuels.

Future developments for Caterpillar fuel injection pumps could incorporate coordinating state-of-the-art sensor innovation for continuous execution streamlining and checking.

Likewise, Caterpillar is exploring the exercise of elective fuels, like hydrogen and biofuels, utilizing their insight into fuel injection frameworks to conform to changing economic situations and legitimate prerequisites.

Besides, future advancements are expected to influence performance and fuel economy. Caterpillar is developing a gasoline inoculation pump technology that might save customers money on fuel, contamination, and outworking costs.

Conclusion

In conclusion, Caterpillar’s dedication to excellence in design and innovation is evident in its fuel inoculation pumps. Fuel injection pumps made by Caterpillar are inseparable from precision, trustworthiness, and productivity in both mechanical and electrical frameworks.

Caterpillar pumps are fundamental for improving motor execution and lessening ecological effects since they advance fuel conveyance and firing.

Moreover, Caterpillar excels in sustainability and fuel efficiency through ongoing research and support.

FAQs

What is a Caterpillar fuel injection pump?

It’s a crucial component in Caterpillar marine engines, responsible for delivering precise amounts of fuel into the engine’s combustion chambers.

Why is the Caterpillar fuel injection pump important for fuel efficiency?

The fuel injection pump ensures optimal fuel delivery, maximizing combustion efficiency and minimizing fuel wastage, thus enhancing overall fuel efficiency.

How does the Caterpillar fuel injection pump contribute to engine performance?

By delivering fuel at high pressure and precise timing, the injection pump facilitates efficient combustion, resulting in improved power output and reduced emissions.

What ensures reliability in Caterpillar fuel injection pumps?

Caterpillar designs its fuel injection pumps to withstand rigorous marine conditions, utilizing robust materials and advanced engineering for durability and consistent performance.

Where can one find genuine Caterpillar fuel injection pumps?

Genuine Caterpillar fuel injection pumps are available through authorized dealerships, ensuring compatibility, reliability, and warranty support for marine engines.